WIRINGINSTRUCTIONS

CAUTION:

1.Topreventtheriskofelectricshockpowersupplytotheequipmentmustbe

keptOFFwhiledoingthewiringarrangement.

2.Terminalsandelectricallychargedpartsmustnotbetouchedwhenthepower

isON.

3.Wiringshallbedonestrictlyaccordingtotheterminallayoutwithshortest

connections.Confirmthatallconnectionsarecorrect.

4.UseluggedterminalstomeetM3.5screws.

5.Toeliminateelectromagneticinterferenceuseofshortwirewithadequate

ratingsandtwistsofthesameinequalsizeshallbemade.

6.Cableusedforconnectiontopowersource,musthaveacrosssectionof1or

greater.Thesewiresshallhaveinsulationcapacitymadeofatleast1.5KV.

INSTALLATIONGUIDELINES

MechanicalInstallation:

Forinstallingthecontroller

1.Preparethepanelcutoutwithproperdimensionsasshown.

2.Removetheclampfromthecontroller.

3.Pushthecontrollerintothepanelcutout.Securethecontrollerinits

placebypushingtheclampfromtherearside.

CAUTION:

The equipment in its installed state must not come in close proximity to any

heating sources, caustic vapors, oils, steam, or other unwanted process by-

products.

!

8

Installation

ELECTRICAL PRECAUTIONSDURINGUSE

Electricalnoisegeneratedbyswitchingofinductiveloadscancreatemomentary

disruption,erraticdisplay,latchup,datalossorpermanentdamagetotheinstrument.

Toreducenoise:

A)UseofMOVacrosssupplyoftemperaturecontroller&snubbercircuits

acrossloadsarerecommended.Partnumbersareasfollows:

1.Snubber:APRC-01.

B)Useseparateshieldedwiresforinputs.

C)Theunitshouldpreferablybeshieldedfromthecontactor.

EMC Guidelines:

1.Use proper input power cables with shortest connections and twisted type.

2.Layout of connecting cables shall be away from any internal EMI source.

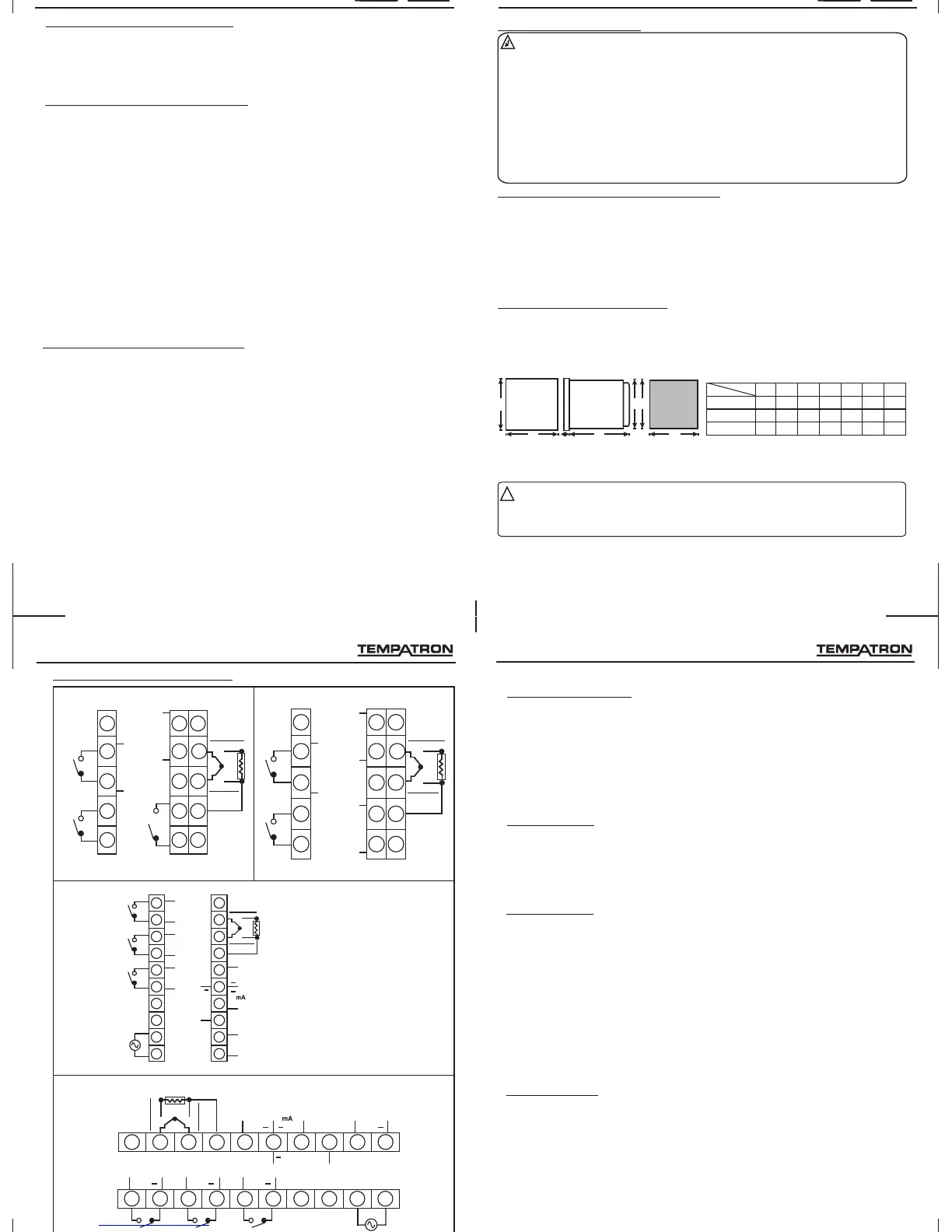

OVERALL DIMENSIONS (Alldimensionsinmm)

E

A

PanelCutout

F

D

B

C

G

A

B C D E F G

PID500

48 48 100 45 7 45 45

96 96

74.5

90

10

92 92

PID330

96 48

74.5

90 10 92 45

PID110

MODEL

S

DIM

! DERIVATIVE APPROACH CONTROL:

AUTO-TUNE OF HEAT/COOL SYSTEMS:

ANALOG OUTPUT-RETRANSMISSION:

Derivative approach control (DAC) helps in reducing overshoot at startup. The control

output cutoff point is derived as DAC x Proportional band. Note that the DAC value is

automatically calculated and fed after autotuning (if tuning is initiated at startup).

During Autotune of heat/cool systems, the controller switches the cooling output (O2) ON

and OFF in addition to the heat output (O1). The heat/cool overlap deadband parameter

(db in Level 2) determines the amount of overlap or deadband between the two outputs

during Autotune.

For most applications, set this parameter to 0.0 prior to starting Autotune. After the

completion of Autotune, this parameter may need to be reset. It is important that external

load disturbances be minimized, and if present, other zone controllers idled as these may

have an effect on the PID constant determination.

Some water cooled processes exhibit an extreme non-linear gain characteristic. That is,

the process cooling gain starts very high and flattens out deeper into the cooling region.

This effect may result in regular oscillations at setpoint as the controller applies heat to

counteract the effect. These processes may benefit from a lower cooling fan setting and/or

reduced water flow in the jacket or manifold. The process heat and cool gains should be

balanced as much as possible, and the controller gains adjusted to the process.

1. The analog retransmission output feature allows the retransmission of the control

output to an external device.

2. The output is scaled by use of Analog low and high scaling points in level 2 of the

programming menu. The analog output will be proportional to PV (derived from

Analog Low and High scaling.)

3. A-LO : Displays the value that corresponds to 0V, 0/4mA as selected.

A-HI : Displays the value that corresponds to 10V or 20mAas selected.

4. Note that the main output selection in level 4 has to be relay 2.

!

!

UserGuide

35

!

!

!

“antireset wind-up”

PROPORTIONAL BAND:

MANUAL RESET:

INTEGRAL TIME:

DERIVATIVE TIME

Proportional band is the area around the set point where the controller is actually

controlling the process; the output is at some level other than 100% or 0%.

Proportional band is expressed in terms of degree centigrade.

If the proportional band is too narrow an oscillation around the setpoint will result. If the

proportional band is too wide the control will respond in a sluggish manner, could take a

long time to settle at set point and may not respond adequately to upsets.

Virtually no process requires precisely 50% output on single output controls or 0% output

on two output controls. The adjustment called manual reset allows the user to redefine the

output requirement at the setpoint. A proportioning control without manual or automatic

reset will settle out somewhere within the proportioning band but likely not on the setpoint.

Integral time is defined as the time, in seconds, which corrects for any offset (between

setpoint and process variable) automatically over time by shifting the proportioning band.

Integral action (also known as “automatic reset”) changes the output power to bring the

process to setpoint. Integral times that are too fast (small times) do not allow the process

to respond to the new output value. This causes over-compensation and leads to an

unstable process with excessive overshoot. Integral times that are too slow (large times)

cause a slow response to steady state errors. Integral action may be disabled by setting

the time to zero. If time is set to zero, the previous integral output power value is

maintained. If integral action is disabled, manual reset is available by modifying the output

power offset (“MNL.r” initially set to zero) to eliminate steady state errors. The controller

has the feature to prevent integral action when operating outside the proportional band.

This feature is called .

Derivative action is used to shorten the process response time and helps to stabilize the

process by providing an output based on the rate of change of the process. In effect,

derivative action anticipates where the process is headed and changes the output before

it actually “arrives”. The derivative time is calculated in seconds. Increasing the derivative

time helps to stabilize the response, but too much derivative time coupled with noisy

signal processes, may cause the output to fluctuate too greatly, yielding poor control.

None or too little derivative action usually results in decreased stability with higher

overshoots. No derivative action usually requires a wider proportional and slower integral

times to maintain the same degree of stability as with derivative action. Derivative action is

disabled by setting the time to zero.

!

34

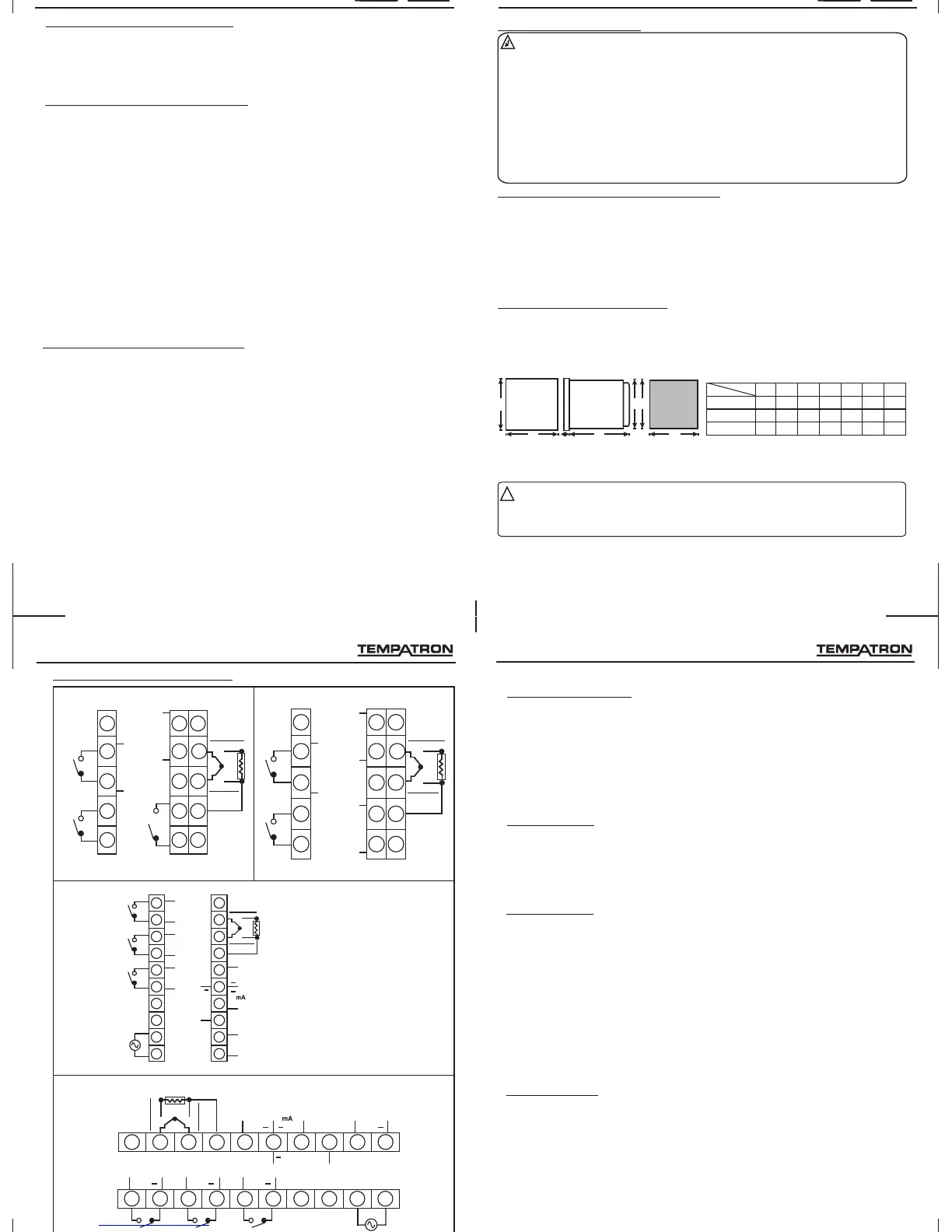

2. TERMINAL CONNECTIONS

9

Installation

PID500

+

SSR1/

ANA OP

COM1

COM2

COM3

NO1

NO2

NO3

+

+

+

+

-

-

-

-

SSR2

SSR3

N

L

-

11

12

13

14

15

16

17

18

19

20

RS485

RTD3

mV

TC/RTD1

+

+

mV

TC/RTD2

-

-

1

2

3

4

5

6

7

8

9

10

+

V

+

+

MI/

CT/

R-SP

PID110

PID330

1

6

8

9 10

5

4

3

2

16 17 18

19 20

15

14

13

1211

7

+

SSR1/

ANA OP

COM1 COM2 COM3NO1 NO2 NO3

+

+

+

+

+

+

SSR2 SSR3

LN

RS485

V

RTD3

mV

TC/RTD1

+

+

mV

TC/RTD2

-

-

-

MI/CT/R-SP

+

RTD3

ANA IP

TC/RTD1

+

+

+

-

ANA IP

TC/RTD2

-

-

RS485

12

7

13 8

14

9

15 10

COM2

SSR1/0-5V/

0-10V/4-20mA

SSR2

NO1

COM1

NO2

2

1

3

4

5

+

-

+

-

L (+)

6

11

(-)N

COM3

NO3

+

-

SSR3

NOTE: Terminals11to15areoptional

NOTE: Validforoptionalconfiguration.

RTD3

ANA IP

TC/RTD1

+

+

ANA IP

TC/RTD2

-

-

7

13 8

14

9

15 10

COM2

SSR1/0-5V/

0-10V/4-20mA

SSR2

NO1

COM1

NO2

2

1

3

4

5

+

-

+

-

L (+)

6

12

11

(-)N

+

-

+

-

RS485

CT/MI/R-SP

UserGuide

Loading...

Loading...