6

Sensortype

Range

Sensortype

Range

J

-200to750 C

o

E

K

-200to1350 C

o

B

T

-200to400 C

o

N

R

0to1750 C

o

L

S

0to1750 C

o

U

C

0to2300 C

o

W

PlatinelII

0to1390 C

o

PT100

-200to750 C

o

+149to1820 C

o

-200to1300 C

o

-200to C600

o

-200to C900

o

0to2300 C

o

-100to850 C

o

Signalinputs:

Inputtype

LinearmV

Voltage

Current

Range

-5to56mV

0to10VDC

0to20mA

Specifications

CE.

AsperBSEN61010.

AsperBSEN61326.

IP66.

Compliance

LVD

EMC

Panelsealing

8.SAFETY ANDEMCSTANDARDS.

9.WEIGHT:

10.HOUSING:

11.INPUTSENSORRANGES(for1 Cresolution):

PID500:195gms;PID110:250gms;PID330:295gms

Flameretardantengineeringplastic.

o

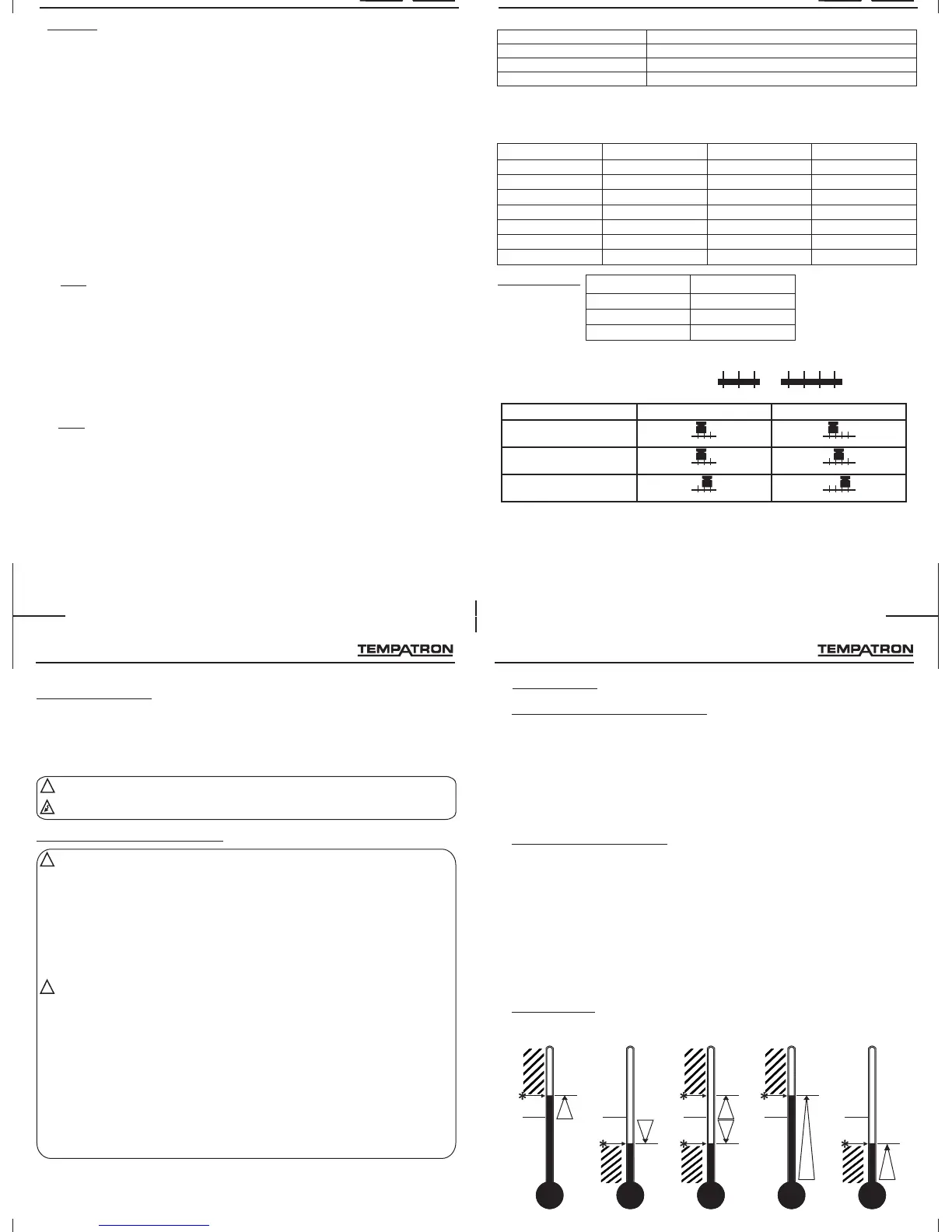

12.INPUTSELECTIONJUMPERASSIGNMENTS:

NOTE: SensorselectiontobedoneinLevel0ofprogrammingalso.

ShortrespectivepinsofJP3&JP4asper

thetablegivenbelowforhardwareselection

ofinputsensortypes:

JP4

FECD

JP3

XBA

4-20mA

(BA)

(CD)

XBA

FECD

TC/RTD/LIN(mV)

Inputtype

0-10V

JP3

(XB)

(XB)

JP4

(FE)

(EC)

XBA

XBA

FECD

FECD

UserGuide

!

How to tune the Zones

To tune, say, Zone 1 program the following:

Zone PID:

There are 4 control Zones each having a set point and associated P, I and D values which

can be programmed as per the process requirements. A control Zone is selected

automatically and implemented as per the set value programmed, to accommodate

changing process requirements. The corresponding P, I,D values will be used to control

the process. The main advantage of Zone PID is in processes where there is a

requirement of frequent tuning, due to change in setpoint. Consider a case where the

process needs to be controlled at two different set points: 100 C and 400 C.

The Zone set points may be programmed as:

1. Zone setpoint 1 (Level1) : 150 C (This implies that for 0 < set1 < 150, Zone1 PID

values will be considered.)

2. Zone setpoint 2 (Level1) : 450 C (This implies that for 150 < set1 < 450, Zone2 PID

values will be considered.)

The P, I, D values for the respective Zones can be manually fed or can be tuned

automatically.

NOTE : Zone setpoint is not the tuning setpoint.

1. Set1 (Online) = 100 C (for eg.) (Zone 1 : 0 - 150 C)

• Set1 < Zone setpoint 1.

• The PID settings derived after tuning are stored in Zone 1.

• After tuning, for 0 < Set1 < 150 C, PID settings of Zone 1 are applicable.

2. Program Tune = ON (in Level 1 or Online)

3. After tuning the controller is automatically loaded with the new PID values.

Now to tune the next Zone, Zone 2, program the following:

1. Set 1 (Online) = 400 C (Zone 2 :150 - 450 C)

• Zone Setpoint 1 < Set 1 < Zone setpoint 2.

• The PID settings derived after tuning are stored in Zone 2.

• After tuning, for 150 < Set1 < 450 C, PID settings of Zone 2 are applicable.

Similarly, the four different Zones can be programmed.

O O

O

O

O O

O

O O

O

Note:

Note:

37

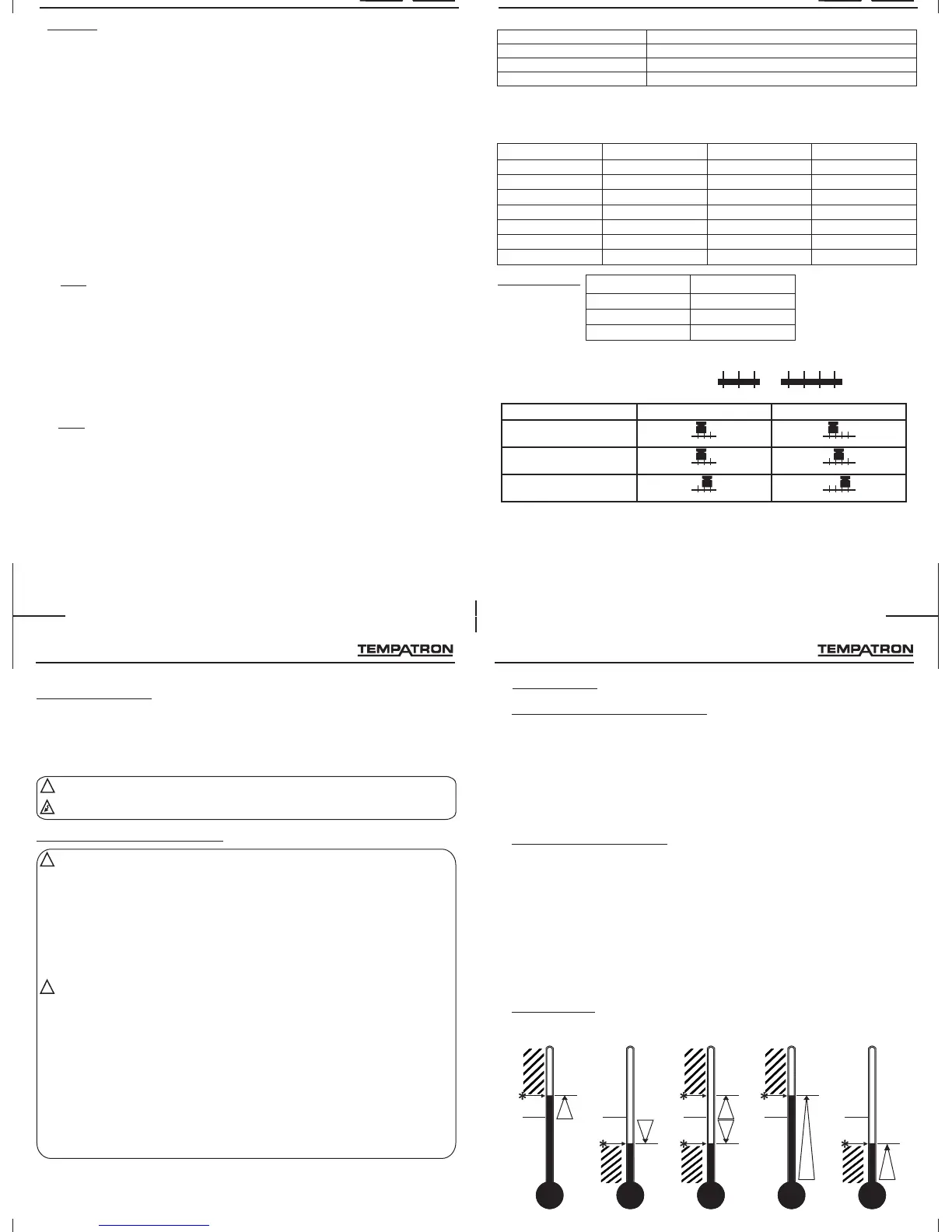

!

1.

Full scale High Alarm:

Refer Fig: d.

Full scale Low Alarm:

Refer Fig: e.

2.

Deviation High Alarm:

Refer Fig: a.

Deviation Low Alarm:

Refer Fig: b.

Deviation Band Alarm:

Refer Fig: c.

3.

ALARM MODES:

Absolute alarms (Independent Alarm) :

Deviation alarms (Error alarm):

BREAK ALARM:

Absolute alarm is a self-existent alarm independent of the main set point.For eg. If the

main set point is 100 C and absolute alarm is set as 110 C, the alarm will be activated at

110 C.

There are two absolute alarms-

sets off alarm signal when temperature rises above set point to a

pre-set temperature above scale minimum.

sets off alarm signal when temperature falls below setpoint to a

pre-set temperature above scale minimum.

This alarm is activated at an error on the main set point. For eg. If the main set point is

100 C and deviation alarm is set to +5 C then the alarm will be activated at 100+5=105

C. Incase of deviation band alarm the alarm will be activated on both sides of set point i.e.

At 95 and 105.

There are three deviation alarms -

sets off alarm signal when temperature rises above a pre-set

temperature above the set point.

sets off alarm signal when temperature falls below a pre-set

temperature below the set point.

sets off alarm signal when temperature rises above or falls below

a pre-set temperature above or below the set point.

Break Alarm: sets off alarm signal when sensor break / under range occurs.

O O

O

O O

O

UserGuide

Deviationlowalarm Deviationbandalarm Fullscalehighalarm FullscalelowalarmDeviationhighalarm

SP2

SP2

SP2

SP2 SP2

SP2

SP

setpoint

SP

setpoint

SP

setpoint

SP

setpoint

SP

setpoint

Alarm

state

Fig:a.Fig:b.Fig:c.Fig:d.Fig:e.

36

!

SAFETY SUMMARY

This manual is meant for the personnel involved in wiring, installation, operation, and

routine maintenance of the equipment. All safety related codifications; symbols and

instructions that appear in this operating manual or on the equipment must be strictly

followed to ensure the safety of the operating personnel as well as the instrument.

If the equipment is not handled in a manner specified by the manufacturer it might

impair the protection provided by the equipment.

Read complete instructions prior to installation and operation of the unit.

Risk of electric shock.

CAUTION:

CAUTION:

1.SAFETY INFORMATION

INSTALLATIONINSTRUCTIONS

CAUTION:

CAUTION:

1.Thisequipment,beingbuilt-in-type,normallybecomesapartofthemaincontrol

panelandinsuchcasetheterminalsdonotremainaccessibletotheenduser

afterinstallationandinternalwiring.

2.Conductorsmustnotcomeincontactwiththeinternalcircuitryoftheequipment

orelseitmayleadtoasafetyhazardthatmayinturnendangerlifeorcause

electricalshocktotheoperator.

3.Circuitbreakerormainsswitchmustbeinstalledbetweenpowersourceand

supplyterminalstofacilitatepower'ON' or'OFF' function.Howeverthisswitchor

breakermustbeinstalledinaconvenientpositionnormallyaccessibletoan

operator.

1.Theequipmentshallnotbeinstalledinenvironmentalconditionsotherthan those

specifiedinthismanual.

2.FuseProtection-Theequipmentdoesnotcontainbuilt-infuse.Installationof

externalfuseforelectricalcircuitryishighlyrecommended.Recommendedrating

ofsuchfuseshallbe275VAC/1Amp.

3.Sincethisisabuilt-intypeequipment(findsplaceinmaincontrolpanel),its

outputterminalsgetconnectedtohostequipment.Suchequipmentshallalso

complywithbasicEMI/EMCandsafetyrequirementslikeBSEN61326-1and

BSEN61010respectively.

4.Thermaldissipationofequipmentismetthroughventilationholesprovidedon

chassisofequipment.Suchventilationholesshallnotbeobstructedelseitcan

leadtoasafetyhazard.

5.Theoutputterminalsshallbestrictlyloadedtothemanufacturerspecified

values/range.

!

!

7

Installation

MAINTENANCE

1.The equipment should be cleaned regularly to avoid blockage of ventilating parts.

2.Use soft cloth for cleaning. Do not use isopropyl alcohol or any other organic

cleaning agent.

Loading...

Loading...