UserGuide

ADJUSTMENTSEQUENCE

SYMPTOM SOLUTION

SlowResponse

DecreasePB

(1)ProportionalBand(PB)

Highovershootor

Oscillations

IncreasePB

SlowResponse

DecreaseIT

(2)IntegralTime(IT)

Instabilityor

Oscillations

IncreaseIT

SlowResponseor

Oscillations

DecreaseTD

(3)DerivativeTime(TD)

HighOvershoot

IncreaseTD

33

USERGUIDE

n AUTOTUNING:

Auto tuning is a function whereby the controller

learns the process characteristics by itself and

automatically sets the required P,I and D values.

The auto-tuning function can be activated at any

time during the process after power ON , while

temperature is rising or when control has

stabilized. Autotune is indicated by T LED blinking

After the auto tuning procedures are completed,

the T LED will stop flashing and the unit will

revert to PID control by using its new PID values.

The PID values obtained are stored in the nonvolatile memory.

Initial setup for a new process

The set point is changed substanitally from the previous auto-tuning value.

The control result in unsatisfactory.

The following controller parameters are automatically adjusted by Auto- tune

according to the characteristics of the process:

Proportional Band (Pb-1)

Integral Time (It-1)

Derivative Time (dt-1)

Input Filter (FtC)

The auto-tuning is applied in cases of:

=

=

=

If the control performance by using auto-tuning is still unsatisfactory, the following rules

can be applied for further adjustment of PID values:

setpoint

Temp.

Proportionalband

PID-timeproportioning

withautoreset&rate

Reduced overshoot

Time

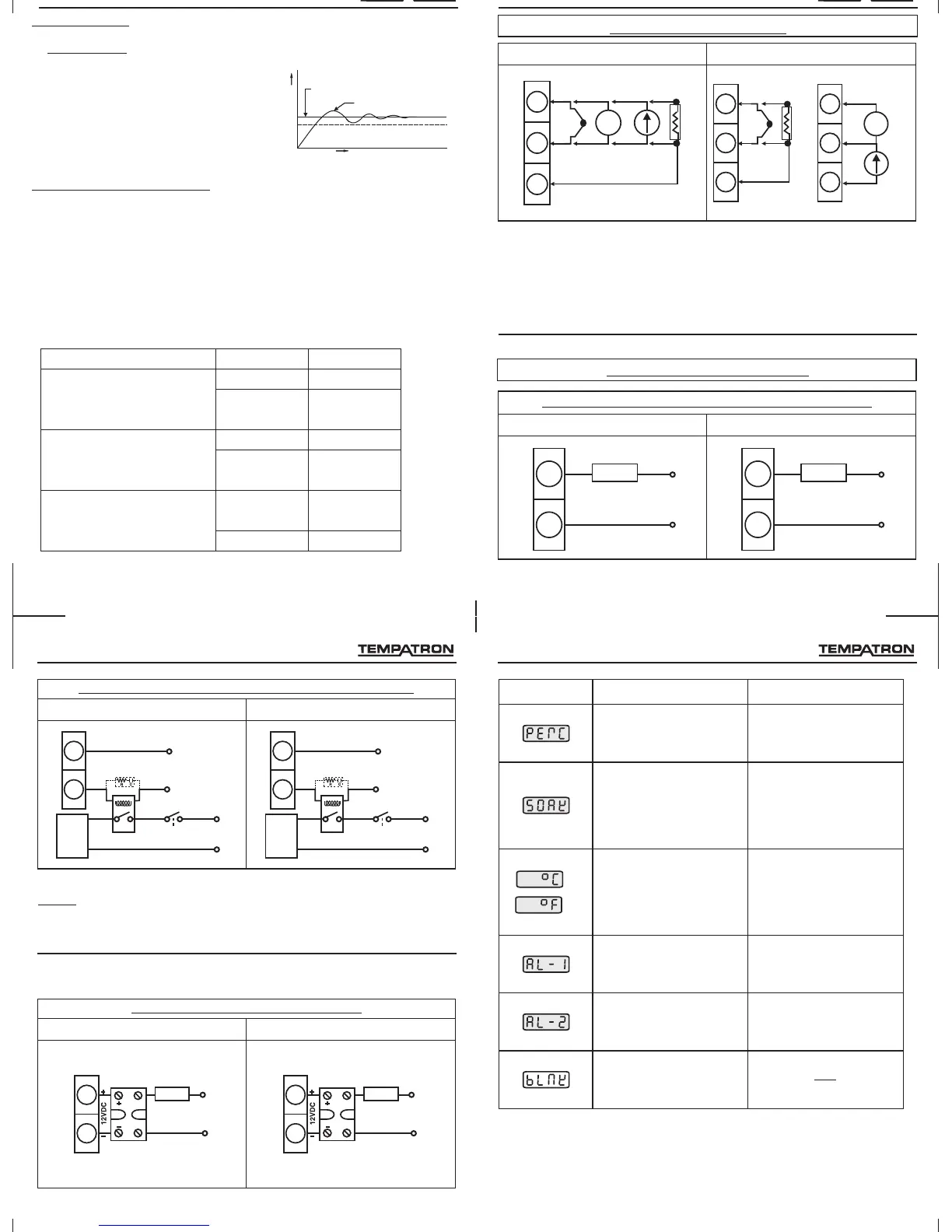

3.SENSORINPUTWIRING

TC - Thermocouple (J, K, T, R, S, C, E, B, N, L, U, W, Platinel II).

V - Voltage Input (0 to 10 V DC).

mA- Current Input (0 to 20mA DC)

RTD - PT100.

NOTE : 1) Refer input type selection in level 0 of programming menu.

2) For PID500 refer input jumper selection as in point no. 12 on page 6.

3) For 2 wire RTD short terminals 8 & 9 (for PID500) and terminals 3 & 4

(for PID110 & PID330) .

4.CONTROL OUTPUTWIRING

4

5

LOAD

230VAC

SUPPLY

NO

COM

10

Installation

RTD2

7

8

9

TC

+

-

V

+

-

+

-

mAV

RTD3

RTD1

PID500 PID110&330

PID500 PID110&330

11

12

LOAD

230VAC

SUPPLY

NO

COM

Fig1.Output1-Relaytodriveload(resistiveloadlessthan1A).

5

6

7

V

+

-

mA

V

RTD2

2

3

4

TC

+

-

RTD3

RTD1

+

-

N

L

N

L

32

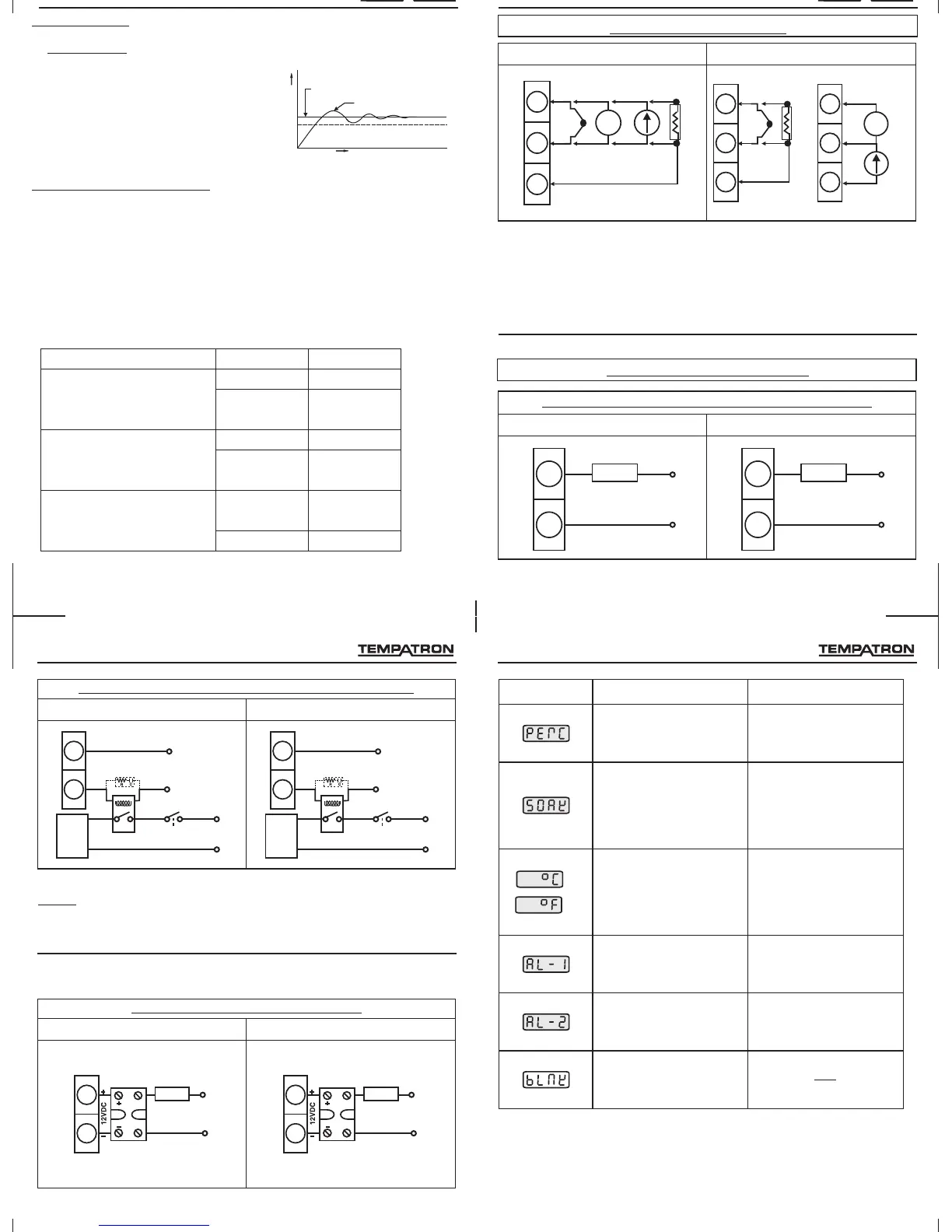

DISPLAY CONDITIONDISPLAY DESCRIPTION

Outputpercentage

Elapsedsoaktime

Temperatureunit

Alarmacknowledge1

Alarmacknowledge2

Blank

Programming

This parameter is read only

and cannot be altered.

Note: This parameter is

prompted only if Ramp is ON /

Hold. This parameter is read

only and cannot be altered.

Note: This parameter is not

prompted for 0-10 V / 4-20mA.

This parameter is read only

and cannot be altered.

Note: This parameter is

prompted only if Alarm1 is ON

and Latch is ON.

Note: This parameter is

prompted only if Alarm2 is ON

and Latch is ON.

/

PID500 PID110&330

4

5

NO

Snubber(Optional)

(PartNo:APRC-01)

230VAC

SUPPLY

COM

L

LOAD

Contactor

N

Fig3.Output1-PulsedvoltagetodriveSSR.

NOTE: Use snubber as shown above to increase life of internal relay of

temperature controller.

11

Installation

4

5

LOAD

230VAC

SUPPLY

SSR

11

12

NO

Snubber(Optional)

(PartNo:APRC-01)

230VAC

SUPPLY

COM

L

LOAD

Contactor

N

Fig2.Output1-Relay/SSRtodrivecontactor(Forsinglephase).

PID500 PID110&330

11

12

LOAD

230VAC

SUPPLY

SSR

Loading...

Loading...