INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)9MAE

46 440 01 4300 02

Specifications subject to change without notice.

19. Use appropriate methods to seal openings where

combustion air pipe and vent pipe pass through roof or

sidewall.

!

WARNING

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal

injury or death.

DO NOT use cement to join polypropylene venting

systems. Follow the polypropylene venting system

manufacturer’s instructions for installing polypropylene

venting systems.

Optional Installation of the vent pipe

NOTE: DO NOT USE THIS TECHNIQUE FOR

POLYPROPYLENE VENTING SYSTEMS.

This option provides a disconnect point for the vent pipe. The

vent pipe must be cemented to the plastic vent pipe adapter to

maintain a sealed vestibule. See Figure 41 and Figure 42

1. Insert a length of vent pipe through the casing into the

outlet of the vent elbow.

2. Slide the plastic vent pipe adapter over the length of the

vent pipe down to the furnace casing. Mark the pipe

where it is flush with the outlet of the adapter.

3. Remove the pipe from the furnace and the adapter and

cut off any excess pipe.

4. Clean and prime the end of the pipe that is flush with the

vent adapter with a primer that is appropriate for the type

of pipe being used.

5. Re−insert the pipe through the casing into the vent

elbow.

6. Tighten the clamp around the outlet of the vent elbow.

Torque the clamp to 15 lb−in.

7. Apply cement to the end of the pipe and to the inside of

the plastic vent adapter.

8. Slide the adapter over the vent pipe and align the screw

holes in the adapter with the dimples in the furnace

casing.

9. Pilot drill 1/8−in. screw holes for the adapter in the casing

and secure the adapter to the furnace with sheet metal

screws.

10. Loosen the clamps on the rubber vent coupling.

11. Slide the end of the coupling with notches in it over the

standoffs in the vent pipe adapter.

12. Tighten the clamp of the coupling over the vent pipe

adapter. Torque the lower clamp around the vent pipe

adapter to 15 lb−in.

13. Pilot drill a 1/8−in. hole in the combustion air pipe

adapter.

14. Complete the vent and combustion air pipe as shown in

“Install the Vent and Combustion Air Pipe”

NOTICE

For Polypropylene Venting Systems

When using polypropylene venting systems, all venting ma-

terials used, including the vent terminations, must be from the

same manufacturer.

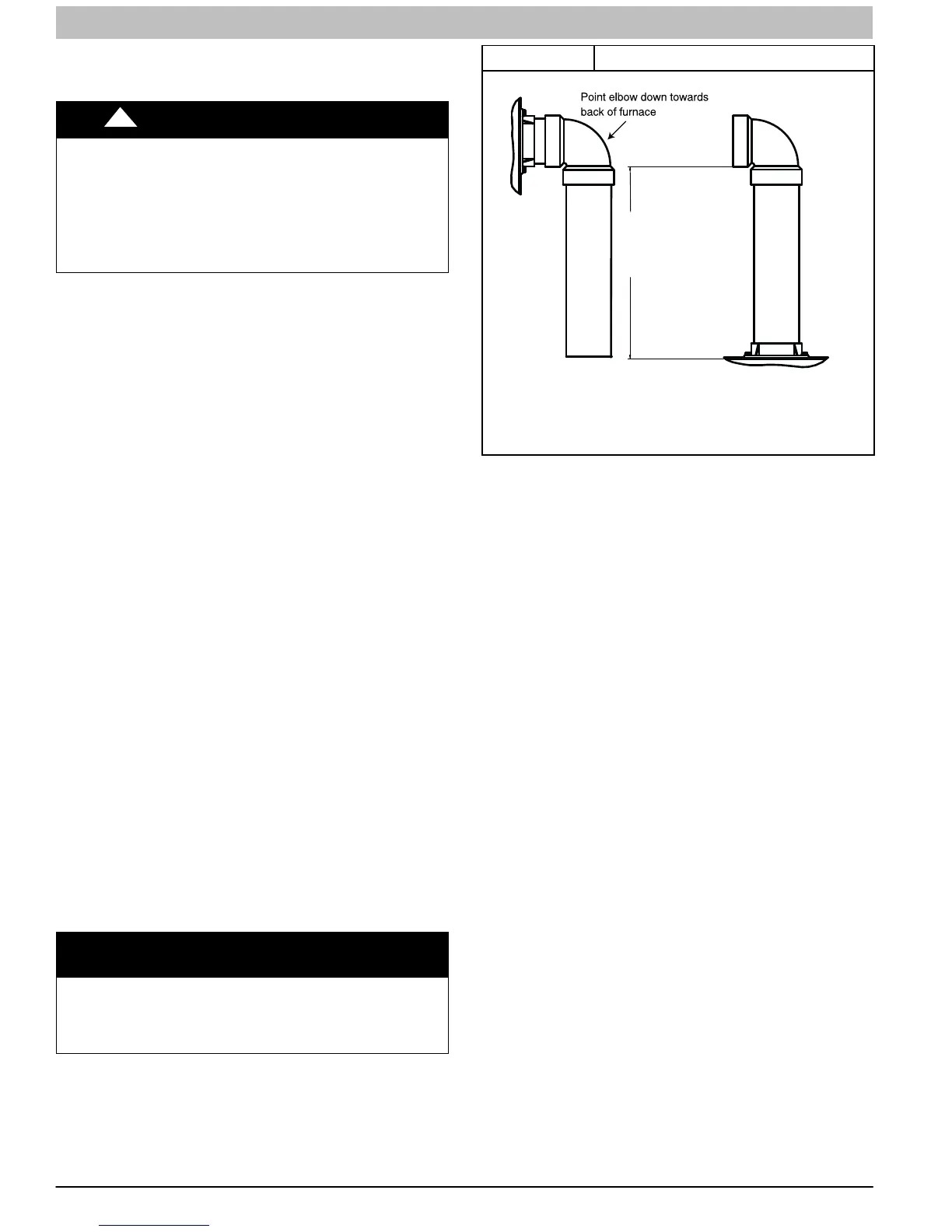

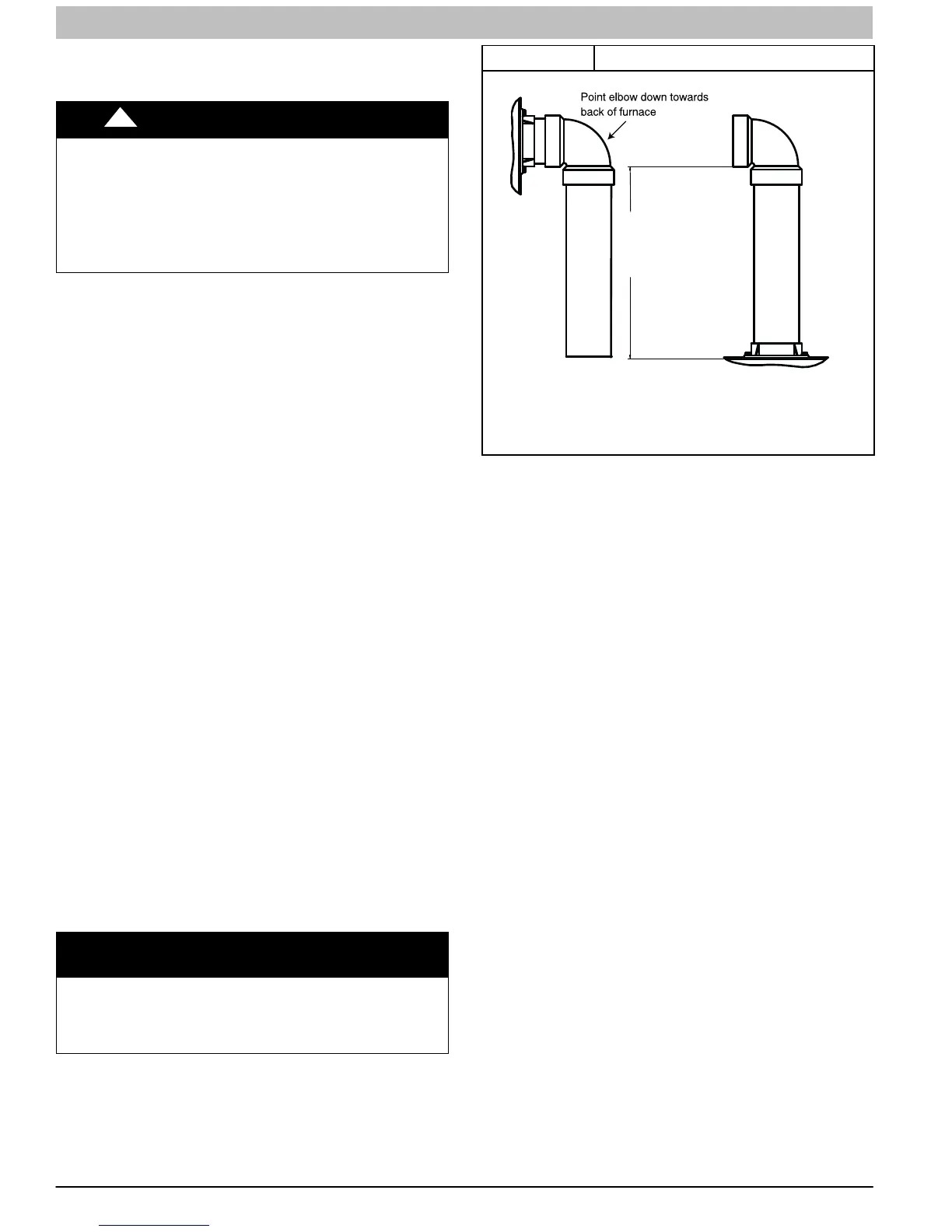

Figure 55 Combustion Air Pipe

A13406

12" (256mm) minimum

to

60”(1524 mm) or

1 additional elbow maximum

CASING SIDE OR TOP ATTACHMENT

COMBUSTION AIR PIPE

(NON-DIRECT VENT FOR ALL MODELS EXCEPT MODULATING UNLESS

INSTALLED IN ATTIC OR CRAWL SPACE)

Installing the Vent Termination

Roof Terminations

A roof termination of any type will require a 4-in. (102 mm)

flashing for a 2−in. (50 mm ND) concentric vent or a 5−in. (127

mm) diameter flashing for a 3-in. (80 mm ND) concentric vent

kit. For 2-pipe or single pipe vent systems, a flashing for each

pipe of the required diameter will be necessary.

It is recommended that the flashing be installed by a roofer or

competent professional prior to installing the concentric vent.

The terminations can be installed on a flat or pitched roof.

Concentric Vent

Single or multiple concentric vent must be installed as shown in

Figure 46. Maintain the required separation distance between

vents or pairs of vents as shown in Figure 46 and all

clearance shown in Figure 58.

NOTE: Follow the instructions of the vent terminal

manufacturer. These instructions are provided as a reference

only.

Cut one 4−in. (102 mm) diameter hole for 2−in. (50 mm ND) kit,

or one 5−in. (127 mm) diameter hole for 3−in. (80 mm ND) kit in

the desired location.

Loosely assemble concentric vent/combustion air termination

components together using instructions in kit.

Slide assembled kit with rain shield REMOVED through hole in

wall or roof flashing.

NOTE: Do not allow insulation or other materials to accumulate

inside of pipe assembly when installing it through hole.

Disassemble loose pipe fittings. Clean and cement using same

procedures as used for system piping. DO NOT CEMENT

POLYPROPYLENE FITTINGS.

Two−Pipe (Direct Vent)Terminations

Two pipe vent terminals must be installed as shown in

Figure 46 and Figure 47. Maintain the required separation

distance between vents or pairs of vents as shown in

Figure 46 and Figure 47 and all clearance shown in Figure 58

or Figure 59.

Loading...

Loading...