November 2021 Maintenance Manual

Programmed Maintenance Procedures

Part No. 1305686GT Scissor Lifts 83

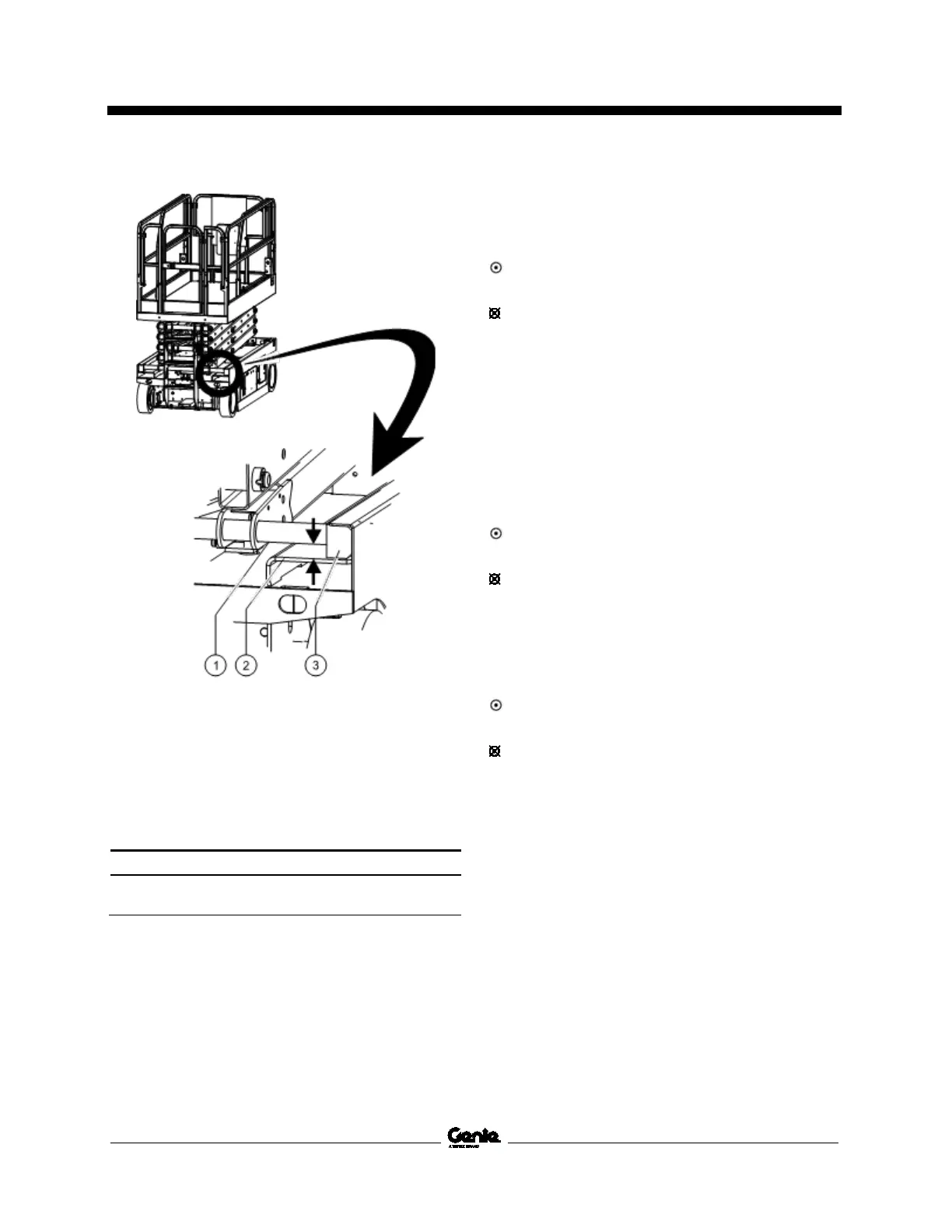

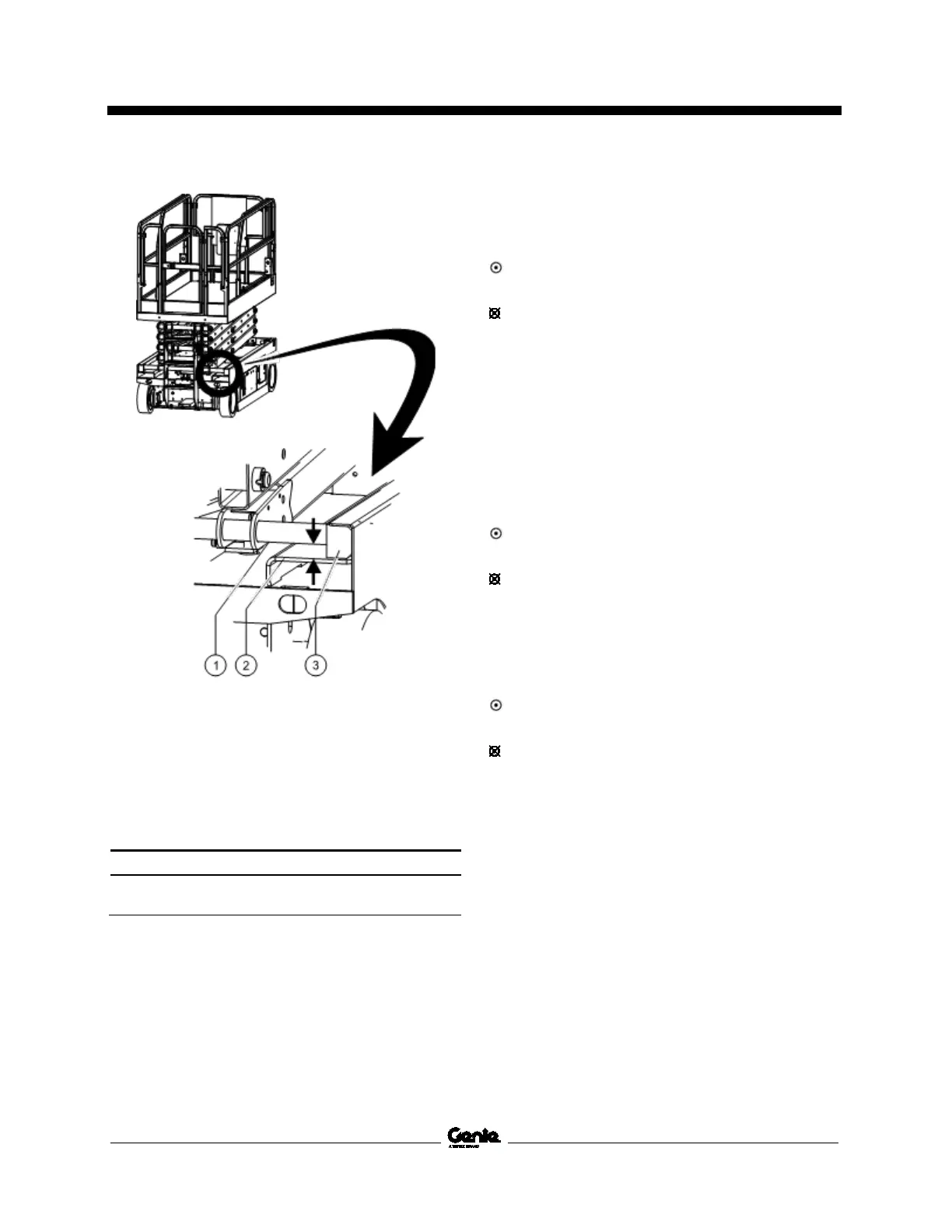

Illustration 2

1 Outer arm cross tube

2 fork lift tube

3 wear pad

3 Apply a thin layer of dry film lubricant to the

area of the chassis where the scissor arm

wear pads make contact.

Cross tube to chassis specification

0.88 i

22.4 m

GS-4655:

1 Measure the thickness of each chassis wear

pad at the non-steer end of the machine.

Result: The measurement is 4.89 inch /

12.42 cm or more. Proceed to step 2.

Result: The measurement is less than

4.89 inch / 12.42 cm. Replace both wear

pads.

2 Apply a thin layer of dry film lubricant to the

area of the chassis where the scissor arm

wear pads make contact.

GS-2669, GS-3369, GS-4069:

1 Measure the thickness of each platform

scissor arm slider blocks at the non-steer end

of the machine.

Result: The measurement is 3.875 inch /

9.843 cm or more. Proceed to step 2.

Result: The measurement is less than

3.875 inch / 9.843 cm. Replace both slider

blocks.

2 Measure the thickness of each chassis

scissor arm upper and lower slider wear pads

at the non-steer end of the machine.

Result: The measurement is 1/4 inch /

6.35 mm or more.

Result: The measurement is less than

11/32 inch / 8.71 mm. Replace both upper

and lower slider wear pads.

Loading...

Loading...