KB21 Service Manual Pub 09-14

90

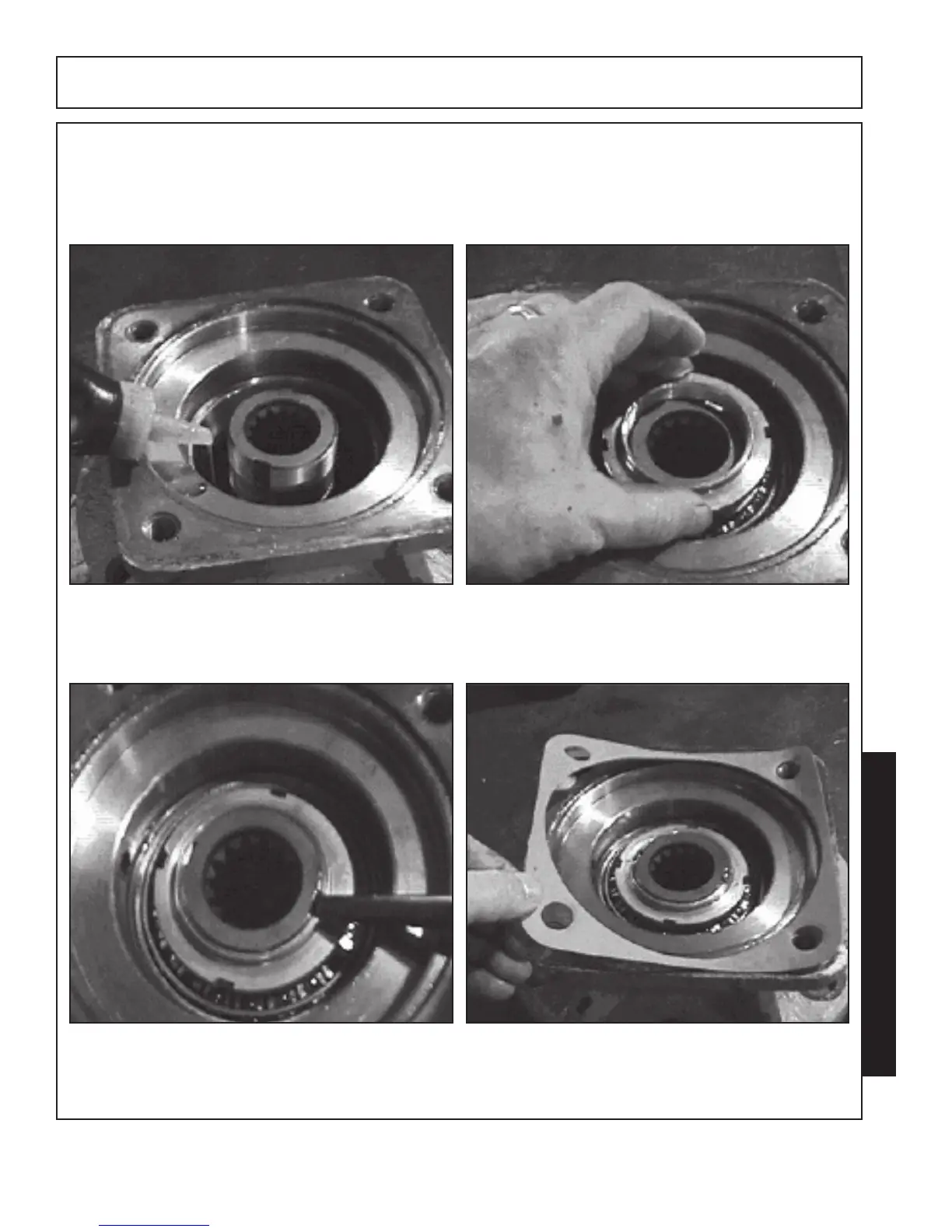

FIGURE - W FIGURE - X

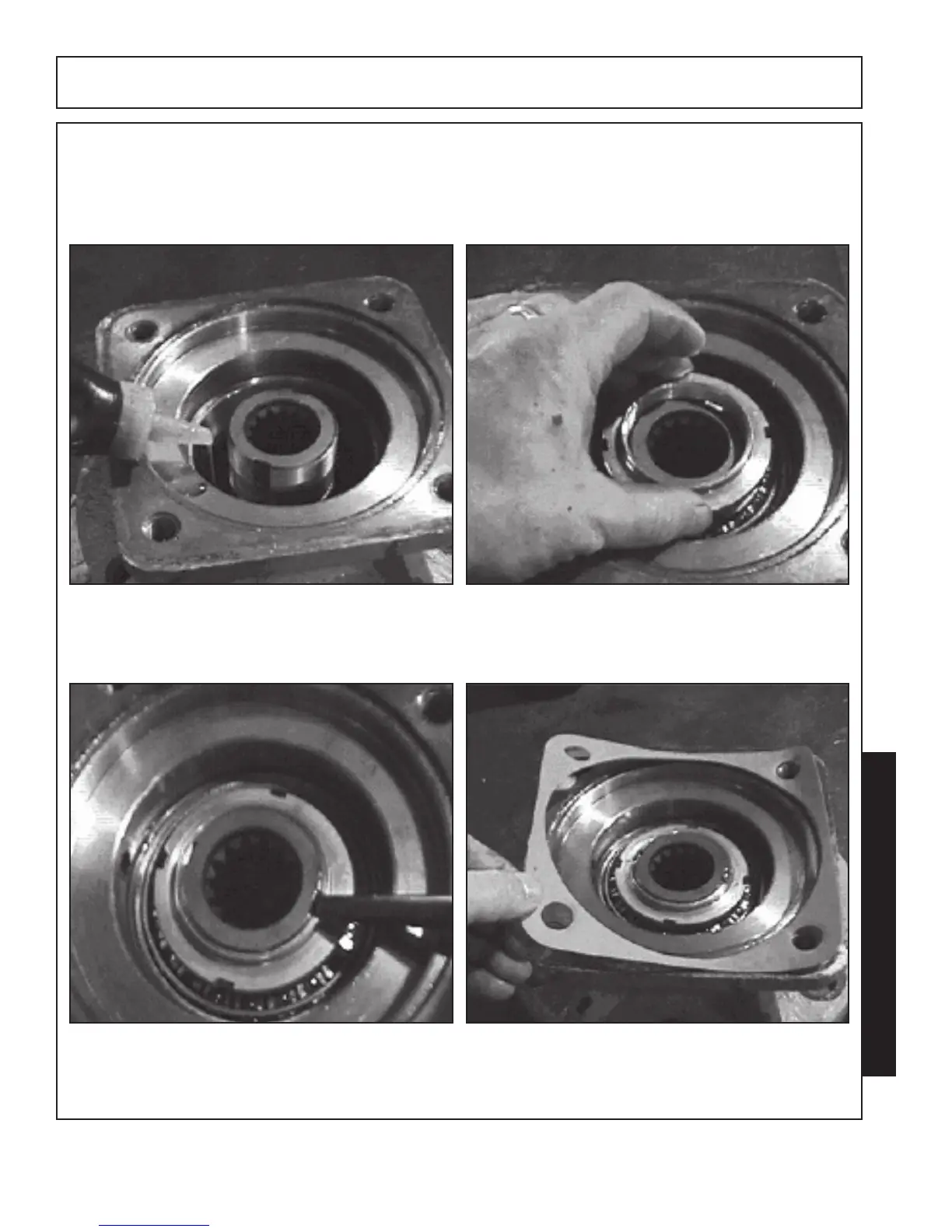

FIGURE - Y

FIGURE - Z

Mowers & Spindles

Fill the spindle housing with EP#2 grease (FIG-W). Th proper oil level is indicated when the spindle is sitting

upright. The oil level should be flush with the bottom of the oil fill hole when it is in this position. Install the upper

bearing and race along with the bearing nut (FIG-X). Tighten the new lock nut with a 4 prong socket and hand

ratchet until tight. Back the nut off until 12 to 15 INCH POUNDS of rolling resistence is achieved.

Use a punch to stake the bearing nut in place. Be sure to stake the nut at both slot locations (FIG-Y). Install the

new motor flange gasket. Apply a thin film of silicone to both sides of the gasket to ensure a good seal (FIG-Z).

Loading...

Loading...