KB21 Service Manual Pub 09-14

111

References

90 - C. PUMP SHAFT ISSUES

Common pump shaft Issues

Straight Shafts

1. Misalignment - This is the most common mode of failure associated

with the straight shaft (no U-Joint) design. Typically this failure will

result in excessive wear to all the splined areas of the shaft assembly

including the pump shaft, coupler and both ends of the drive shaft.

Typical wear results in a barrel shaped pump drive shaft such that the

splines are worn down on each end. Likewise, the internal splines of

the coupler may be worn in a concave shape around the inside diameter.

Progression will result in the total loss of spline engagement and loss of power to the pump. Other

symptoms include pump shaft fatigue failures, fretting and pump bearing failures. Alignment should be

checked with a straight edge between the new pump shaft and the splines of the crank shaft adapter

without the shaft in the system. Likewise, vibration can be observed by watching for high frequency

movement of the shaft during operation.

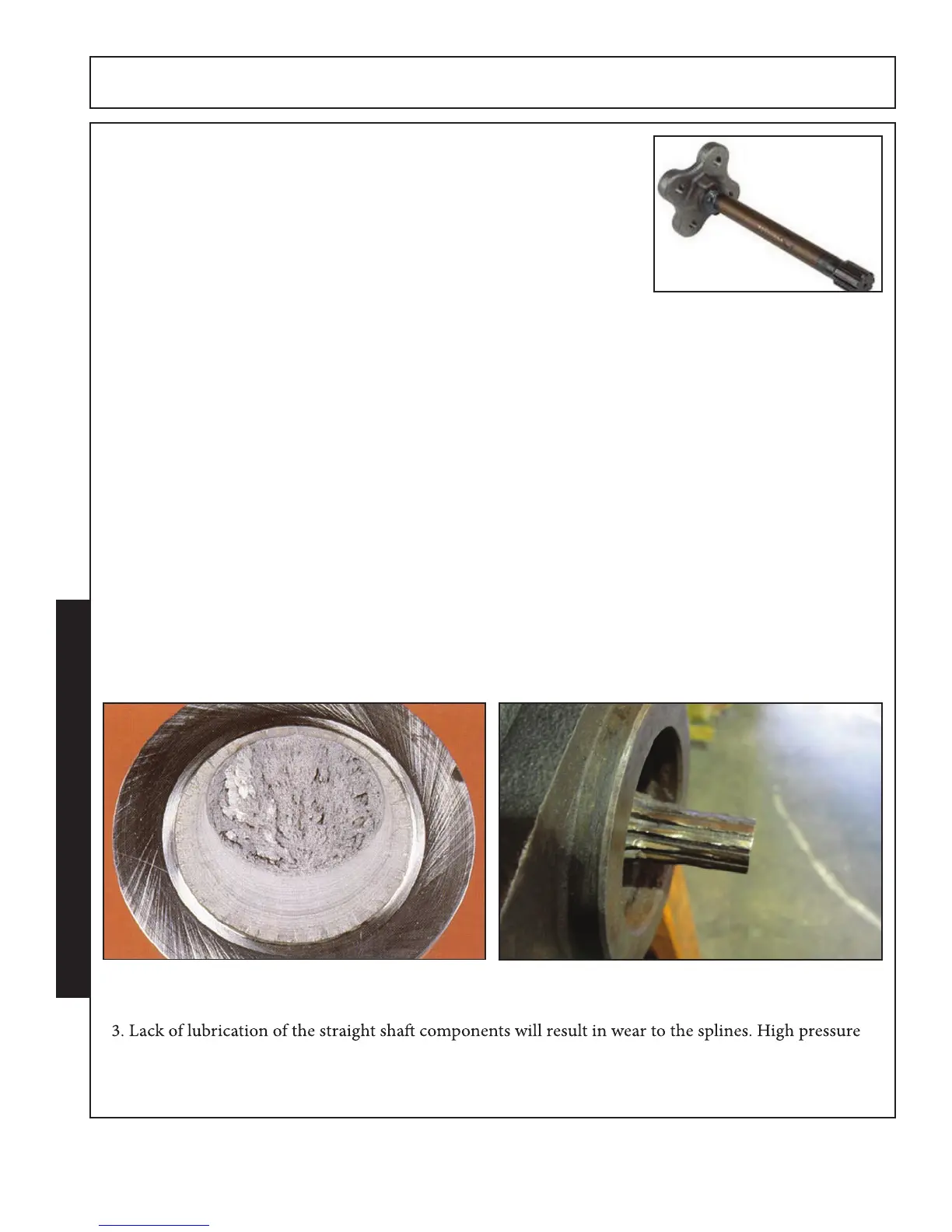

Rotating Bending Fatigue as evidenced by beach marks around the circumference. Final fracture is

Brittle, rough center region. (FIG-X.)

Failure due to cyclical loads from misalignment

2. Sporadic overpowering of the drive system will result in wear of the pump and coupler splines in one

direction as well as fretting corrosion on the pump shaft. This failure is attributable to powering the

mower into heavy brush or limbs rather than a slow controlled cutting operation. (FIG-Y.)

Shaft failure due to sporadic overload - This shaft also shows some rounding indicative of misalign-

ment.

Overpowering will also be indicated by wear on bushings in the crankshaft adapter or related

components.

grease or anti seize compound must be applied to all components during installation and replaced at

regular intervals throughout the life of the machine.

FIGURE-X FIGURE-Y

Loading...

Loading...