22

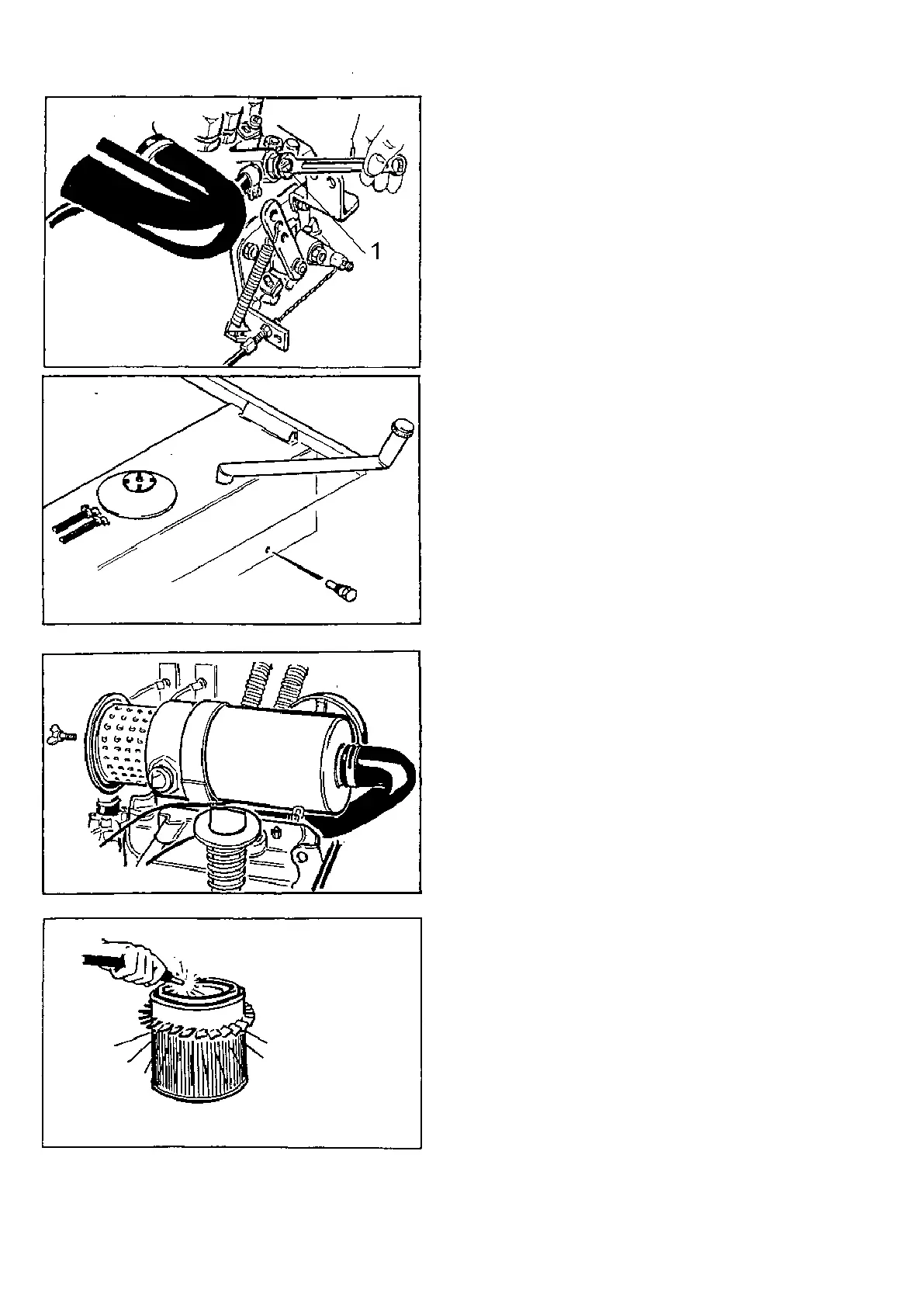

Bleeding of fuel system

If the fuel runs out or any fuel hose has worked loose al-

lowing air to enter, the fuel system must be bled. Open

the bleed screw (1) on the fuel injection pump, and turn

the spanner so that the electric fuel pump then feeds fuel.

Tighten the bleed screw as soon as there are no air bubbles

visible in the fuel owing out.

Fuel tank

Drain and clean the fuel tank once a year to prevent the in-

gress of any condensation water in the fuel injection pump.

Tilt the machine to the left and remove the magnet plug. This

magnet drain plug is located to the left, behind the rear bogie

axle.

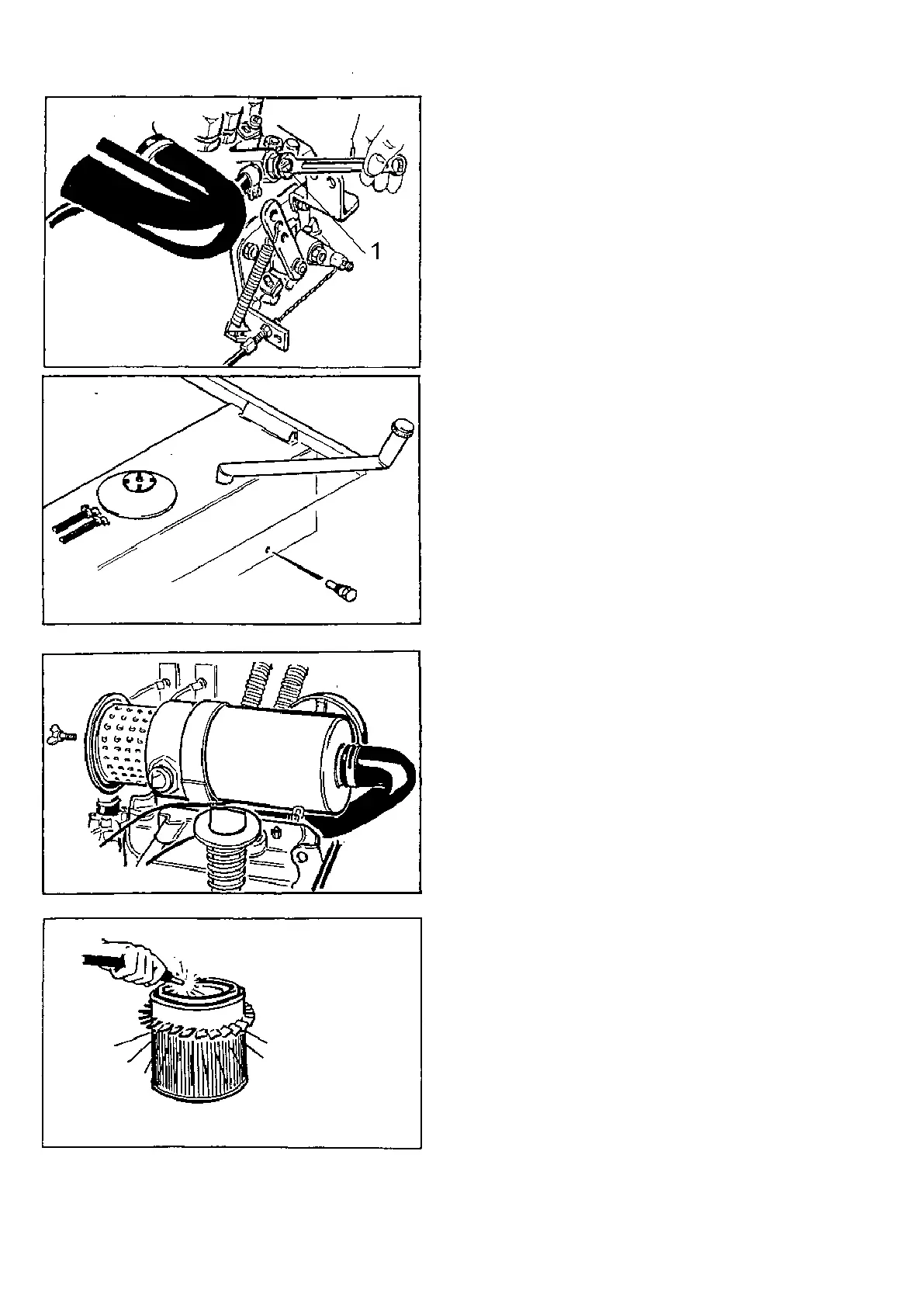

AIR FILTER

The air lter prevents the ingress of dust and other impuri-

ties in the engine. The engine wear is highly dependent on

the cleanliness of the intake air. It is therefore extremely

important to inspect the lter at regular intervals and to look

after it in the correct way.

Do not run the diesel engine under any circumstance without

the air lter or with a damaged lter. Check that the hose

between the air lter and the engine intake is tight.

The air lter is located at the top of the engine. It is of the

dry lter type with a paper lter element.

Cleaning and changing of the air lter

Clean the lter element after every 150 hours of service, e.g.,

with compressed air, see the illustration.

Change the lter element after every 400 hours of service.

• Open the engine hood.

• Detach the air lter from its support.

• Unscrew the wing nut at the end of the air lter and

take out the lter element.

Clean it or change it.

• Replace in the reverse order.

If the engine fails to start, loosen the pressure lines at one

distributor at a time and run with the starter motor until fuel

free from air is sprayed out. Then tighten the pressure line

bolted joints.

Cleaning of lter

Loading...

Loading...