25

Electric welding

If electric welding is to be done on the machine or equip-

ment coupled to the machine, both battery cables must be

disconnected.

Connect the return lead of the welding set as close as pos-

sible to the location of the weld.

Jump starting with booster battery

When jump starting with a booster battery, observe the follo-

wing. Check that the booster battery has the correct voltage.

Let the battery in Terri remain connected up. Connect the

jump lead from the positive (+) pole on the booster battery

to the positive (+) pole on the Terri battery, and then connect

the other jump lead from the negative (-) pole on the booster

battery to the negative (-) pole on the Terri battery.

When the engine has started, rst remove the jump lead bet-

ween the positive (+) poles and then the jump lead between

the negative (-) poles.

Caution! Due to the current inrush the batteries may

burst if a fully charged battery is wrongly connected to a

fully discharged one.

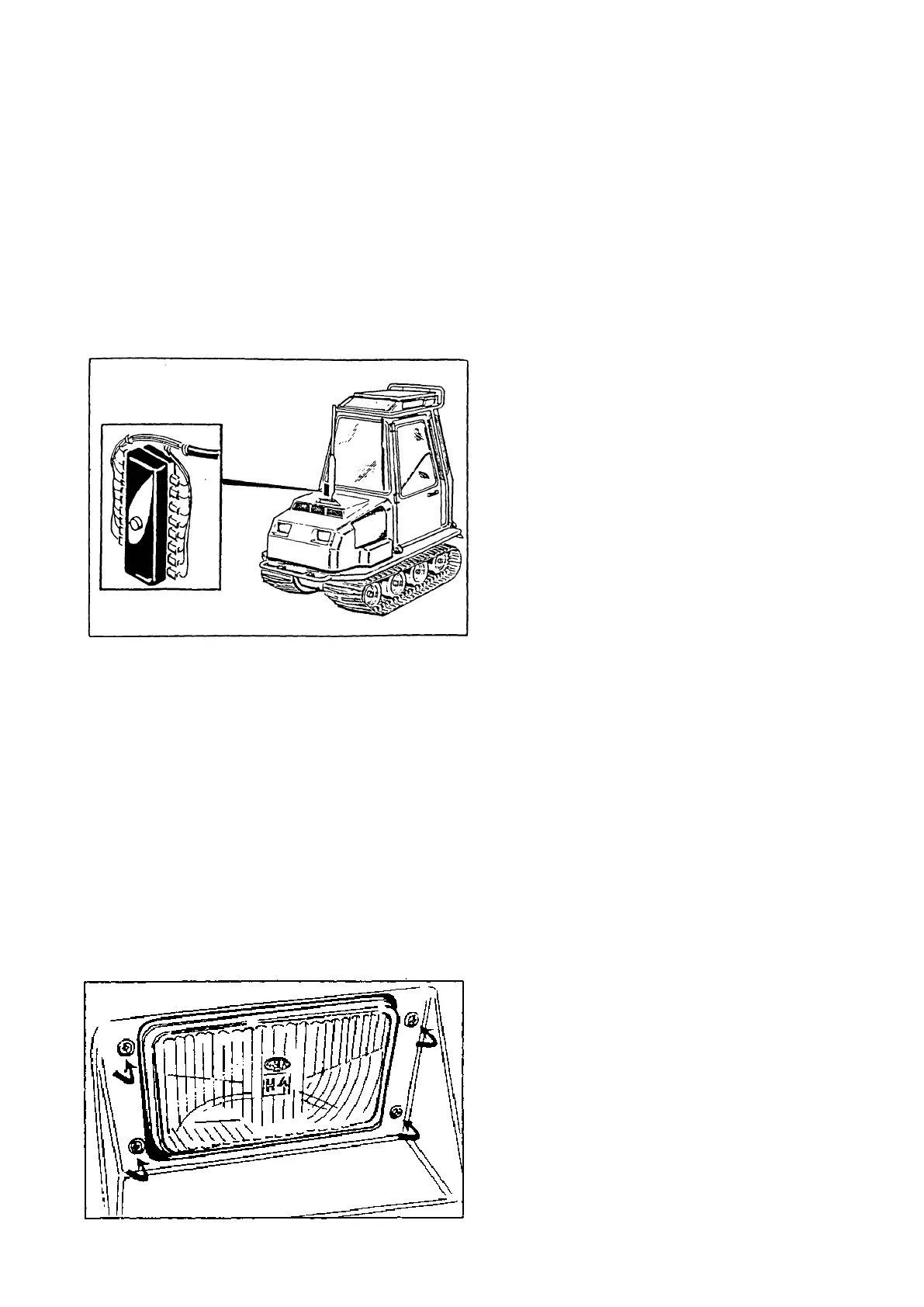

Fuses

The fuses protect the electrical circuits against overloading.

The fusebox is located to the right, below the engine hood.

LIST OF FUSES

1-3. Spare

4. Engine stop coil

5. Trailer drive, Trailer brake

6. Main beams

7. Dip beams

8. Position light, left-hand, tail light, cab, tail

light trailer, right hand, instrument panel

lights

9. Position light, right-hand, rear light trailer,

right-hand, instrument panel lightning

10. Signal horn, working light, rear, rotating warning

light

11. Working lights, side

12. Fuel pump, stop lights, ventilation blower, wind-

screen washer, direction indicators, windscreen

and rear window wipers, oil level light, oil pressure

light, differential lock light, oil temperature gauge,

fuel gauge, cooling water temperature gauge

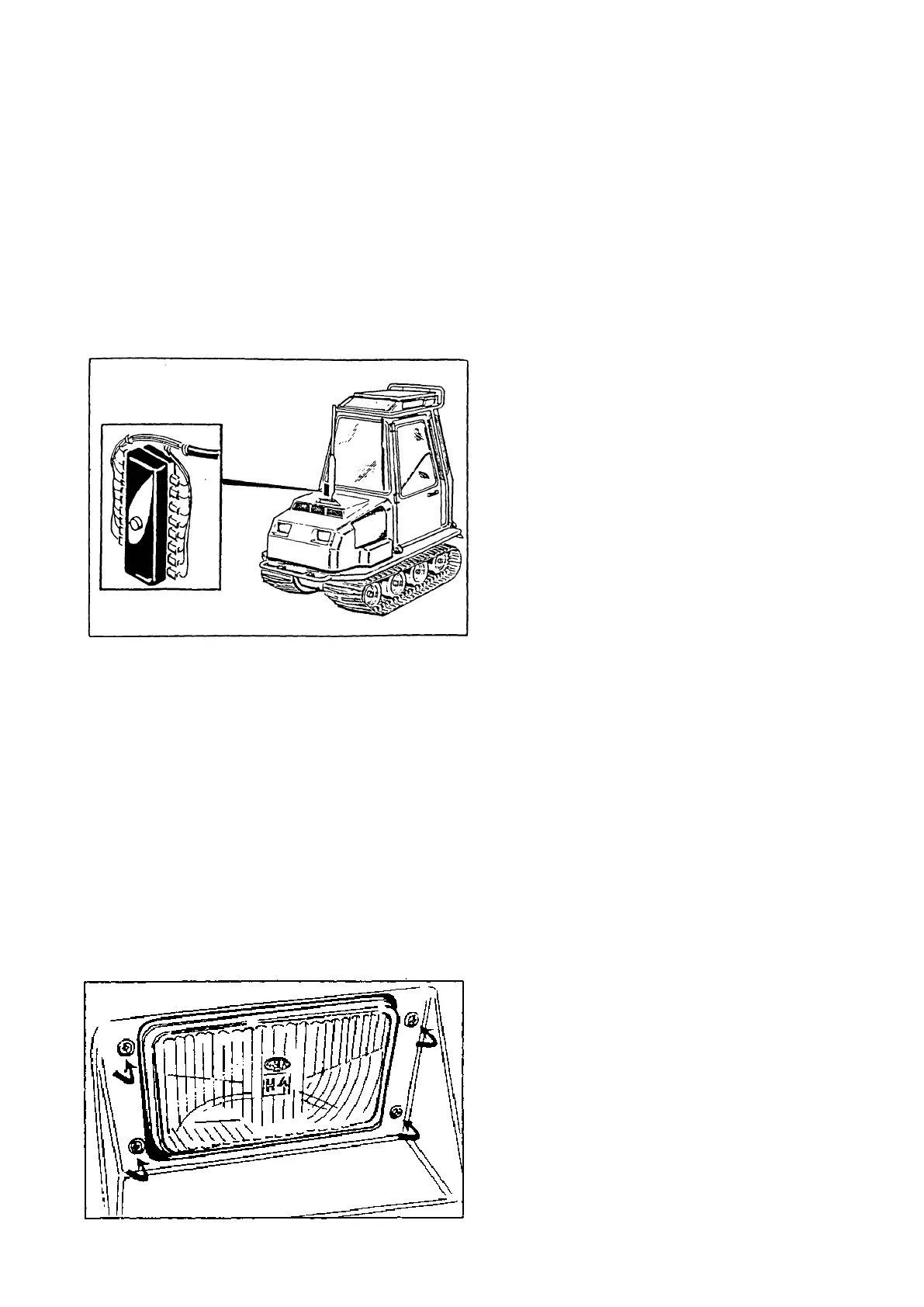

Adjusting of headlights

The headlights are secured with four xing screws, which

at the same time serve as adjusting screws. When the lower

screws are slackened, the light beam is lowered. When, for

example, the left-hand screws are tightened, the light beam

moves to the left.

Loading...

Loading...