OPERATION AND SERVICE INFORMATION

Page 9

Owner’s Manual and Service Guide

Read all of Manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes, Cautions and Warnings

caused by a broken socket when remov-

ing wheels, use only sockets designed

for impact wrench use.

Use caution when inflating tires. Overin-

flation could cause the tire to separate

from the wheel or cause the tire to

explode, either of which could cause

severe injury.

Use caution when inflating tires. Due to the low volume of

the small tires, overinflation can occur in seconds. Over-

inflation could cause the tire to separate from the wheel

or cause the tire to explode.

Tire inflation should be determined by the condition of the

terrain. See GENERAL SPECIFICATIONS section for

recommended tire inflation pressure. For outdoor appli-

cations with major use on grassy areas, the following

should be considered. On hard turf, it is desirable to have

a slightly higher inflation pressure. On very soft turf, a

lower pressure reduces the possibility of tires cutting into

the turf. For vehicles being used on paved or hard sur-

faces, tire inflation pressure should be in the higher

allowable range, but under no condition should inflation

pressure be higher than recommended on tire sidewall.

All four tires should have the same pressure for opti-

mum handling characteristics. Be sure to install the valve

dust cap after checking or inflating.

The vehicle is fitted with low pressure tubeless tires

mounted on one piece rims; therefore, the most cost

effective way to repair a puncture in the tread is to use a

commercial tire plug.

Tire plug tools and plugs are available at most

automotive parts outlets and have the advan-

tage of not requiring the tire be removed from the wheel.

If the tire is flat, remove the wheel and inflate the tire to

the maximum recommended pressure for the tire.

Immerse the tire in water to locate the leak and mark with

chalk. Insert tire plug in accordance with manufacturer’s

instructions.

To reduce possibili-

ty of severe injury,

be sure mounting/

demounting machine is anchored to floor.

Wear OSHA approved safety equipment

when mounting/demounting tires.

If the tire is to be removed or mounted, the tire changing

machine manufacturer’s recommendations must be fol-

lowed in order to reduce possibility of severe injury.

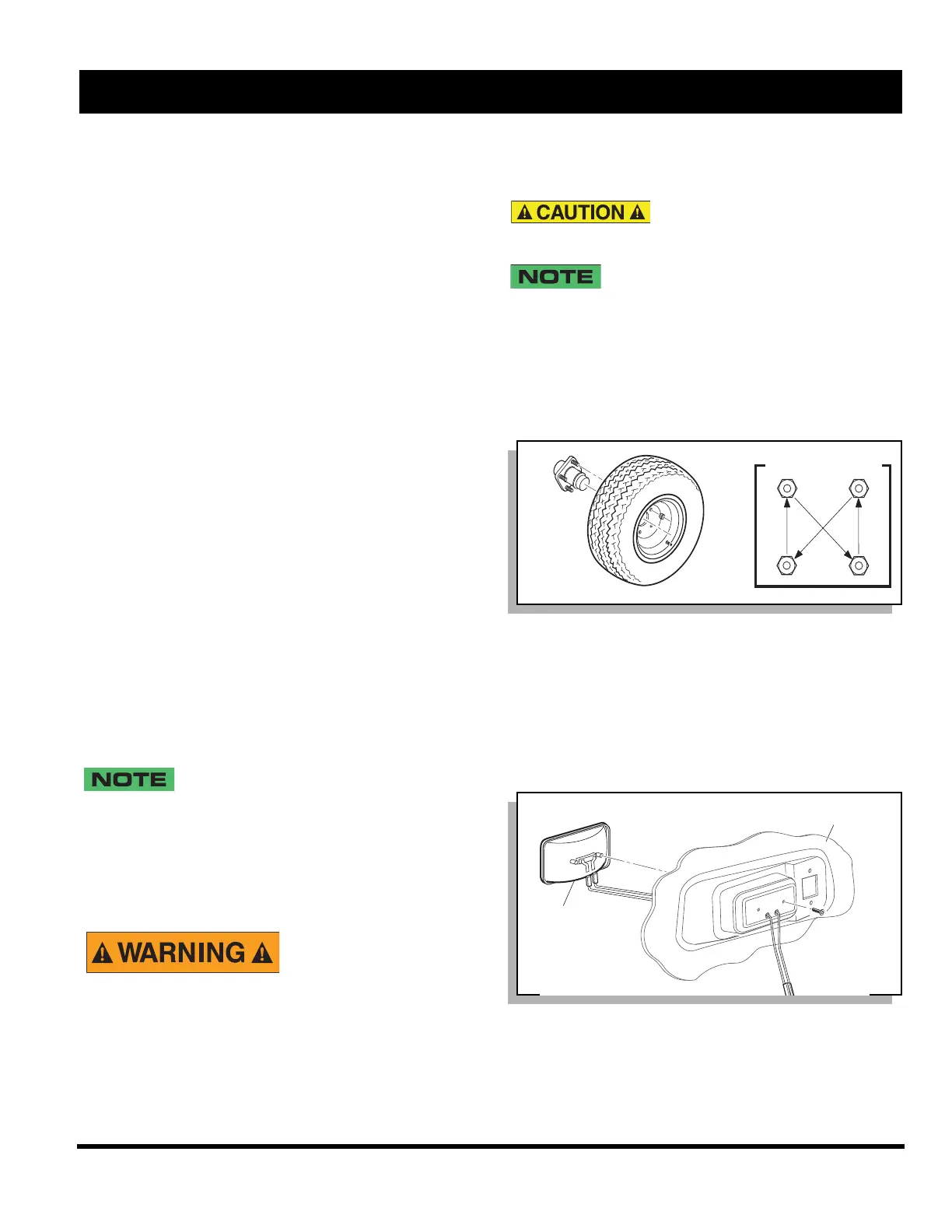

Wheel Installation

To reduce the possibility of com-

ponent damage, do not tighten

lug nuts to more than 85 ft. lbs. (115 Nm) torque.

It is important to follow the ‘cross sequence’

pattern when installing lug nuts. This will

assure even seating of the wheel against the hub.

With the valve stem to the outside, mount the wheel onto

the hub with lug nuts. Finger tighten lug nuts in a ‘cross

sequence’ pattern (Ref Fig. 10 on page 9) . Tighten lug

nuts to 50 - 85 ft. lbs. (70 - 115 Nm) torque in 20 ft. lbs.

(30 Nm) increments following the ‘cross sequence’ pat-

tern.

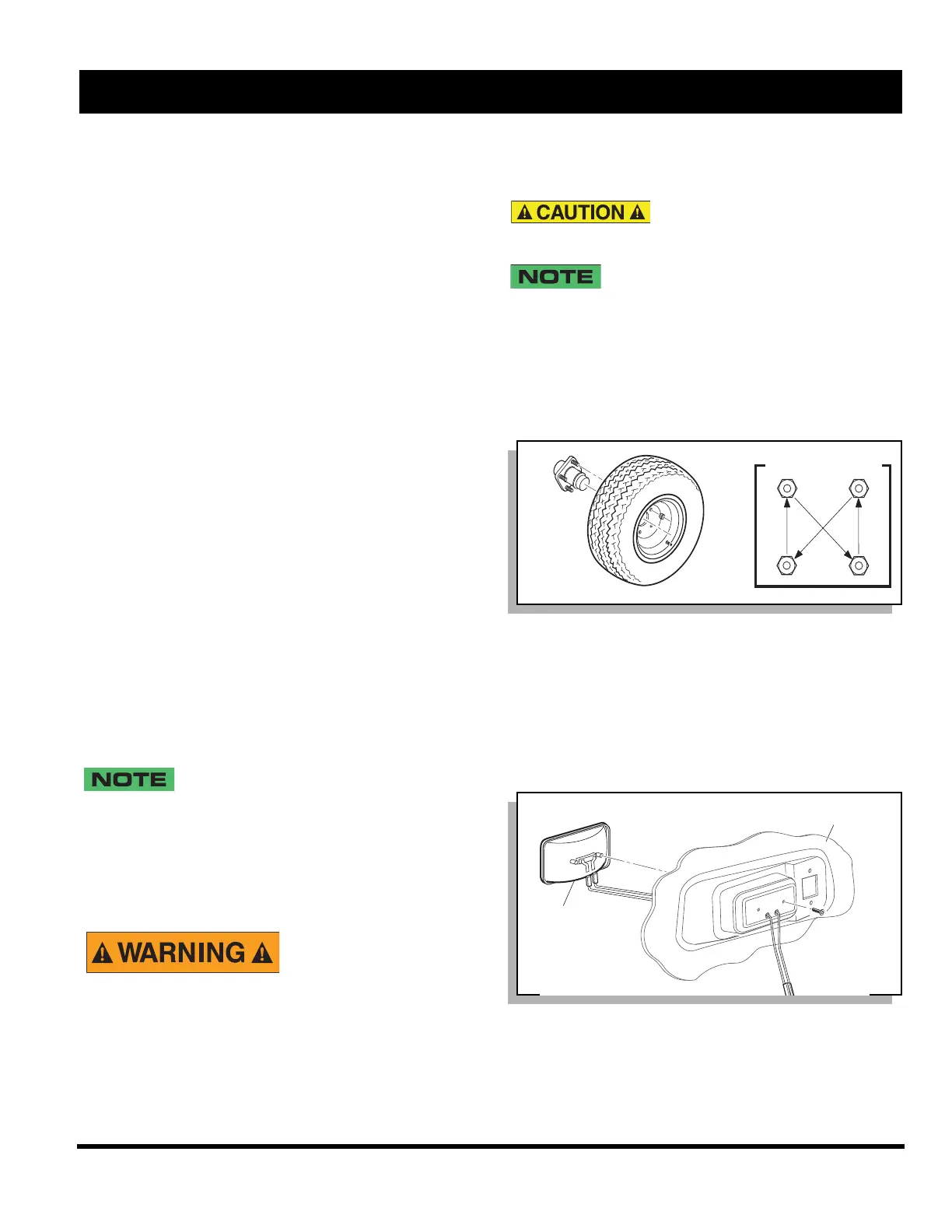

HEADLIGHT REPLACEMENT

For vehicles with headlights mounted in cowl, locate the

two screws on backside of cowl that secure headlight

(Ref Fig. 11 on page 9). Remove screws, pull headlight

out and disconnect wires. Connect wires to new head-

light, install in cowl and secure with screws previously

removed.

FUSE REPLACEMENT

To replace fuses, locate the fuse block under the driver

side seat. Pull out old fuse and replace with a new auto-

motive type fuse. Headlights and fuses are available

Fig. 10 Wheel Installation

Fig. 11 Headlight Replacement

Tire style

may vary

1

2

3

4

'Cross Sequence'

Ref Whi 1

Headlight

Bulb

of Cowl

Loading...

Loading...