12

OPERATION section 4.7

Operating Instructions for Electric PTO Clutch (Serial No. 1642 - )

follow these steps for implement drive belt installation:

1. Place the correct size implement drive belt

around the left hitch arm of the implement

before attaching to the quick hitch front lift. See

the belt size chart (section 4.7) for belt sizes.

2. Attach the implement to the front lift. Push down

on the latch handle to open latches. Pull up to

lock latches.

3. Stop engine and release the belt tension

adjustment lever by moving it as far as it will go

toward the rear.

4. Install the implement drive belt on the double

idler pulley.

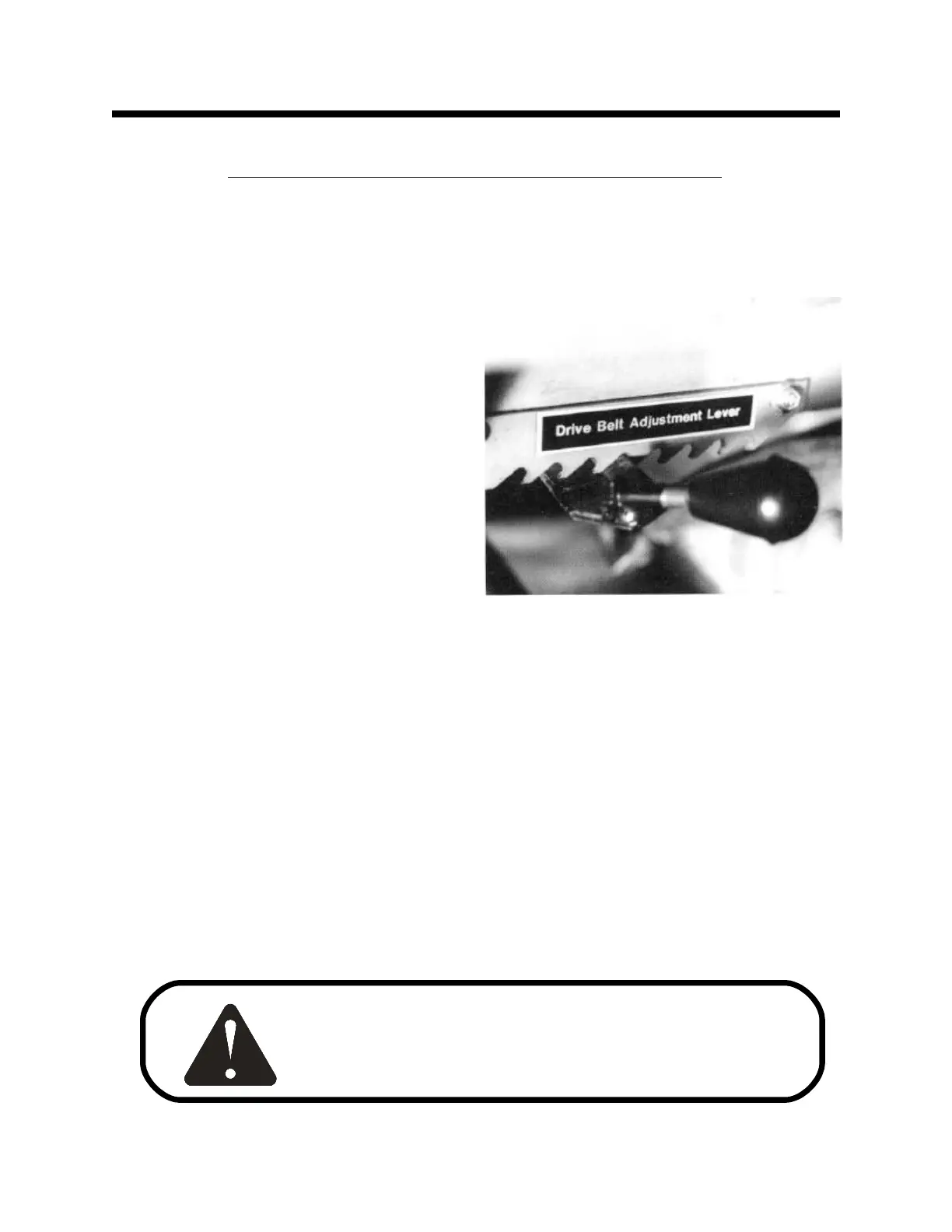

5. Each time a PTO belt driven attachment is

installed, it is necessary to adjust the drive belt

tension. This is done by moving the belt

tension adjustment lever on the left side of the

front tractor frame. (See Photo 4A) Proper

tension is very important! The proper setting is

obtained by moving the lever two notches after

all slack is taken up on the drive belts. If drive

belt slips, tighten one additional notch.

6. The PTO clutch is engaged or disengaged with the PTO push-pull switch. Engage the clutch with the

engine at approximately 1/2 throttle.

7. NOTE: The operator must be seated for the PTO electric clutch to operate. Do not attempt to by-pass this

safety device.

8. SPECIAL INSTRUCTION FOR DIESEL ENGINES: To stop the engine... Pull the knob on the fuel shut-off

cable and hold it until the engine stops. Push it in after the engine stops so the engine is ready to start the

next time. Engine will not start with the fuel shut-off knob pulled out.

Photo 4A - Belt Tension Adjustment Lever

CAUTION!

DO NOT ENGAGE CLUTCH WITH ENGINE AT FULL THROTTLE.

STARTING HEAVY LOADS AT FULL THROTTLE WILL SHORTEN

CLUTCH AND/OR BELT LIFE.

Loading...

Loading...