Pagina 25 di 48

STDITR01ADP2090EV TECNOFRIGO TUSCANY srl

Adjustment of the gas burner

CAUTION! The burner and the metal parts surrounding it can become very hot. Be careful

not to burn yourself.

1. Unscrew the burner observation glass cover.

2. Verify that the gas supply to the dehumidifier is switched on.

3. Open the gas supply valve.

4. Measure the supply pressure of the gas using the pressure gauge at the inlet of the gas train,

pressure must not exceed the maximum allowed value. The pressure must be between 20 and

30 mbar.

NOTE! If the gas supply pressure exceeds 30 mbar, a reduction valve must be inserted in

the gas suction line.

5. Verify that the low pressure switch is set to 5 mbar. If necessary, set the pressure using the setting

wheel.

6. Verify that there are no leaks in the gas ramp leading to the burner.

7. Set the differential pressure on the regulating airflow pressure switch to 50Pa. This operation

serves to avoid disconnection of the automatic burner device during air flow regulation.

8. Set the main switch to position 1 or ON.

9. Start the unit by setting the mode in the MAN position (100%) on the display.

10. Verify that the rotor turns in the direction indicated by the arrows. If the rotation direction is the

wrong one, exchange the connections of the incoming cables in the general switch.

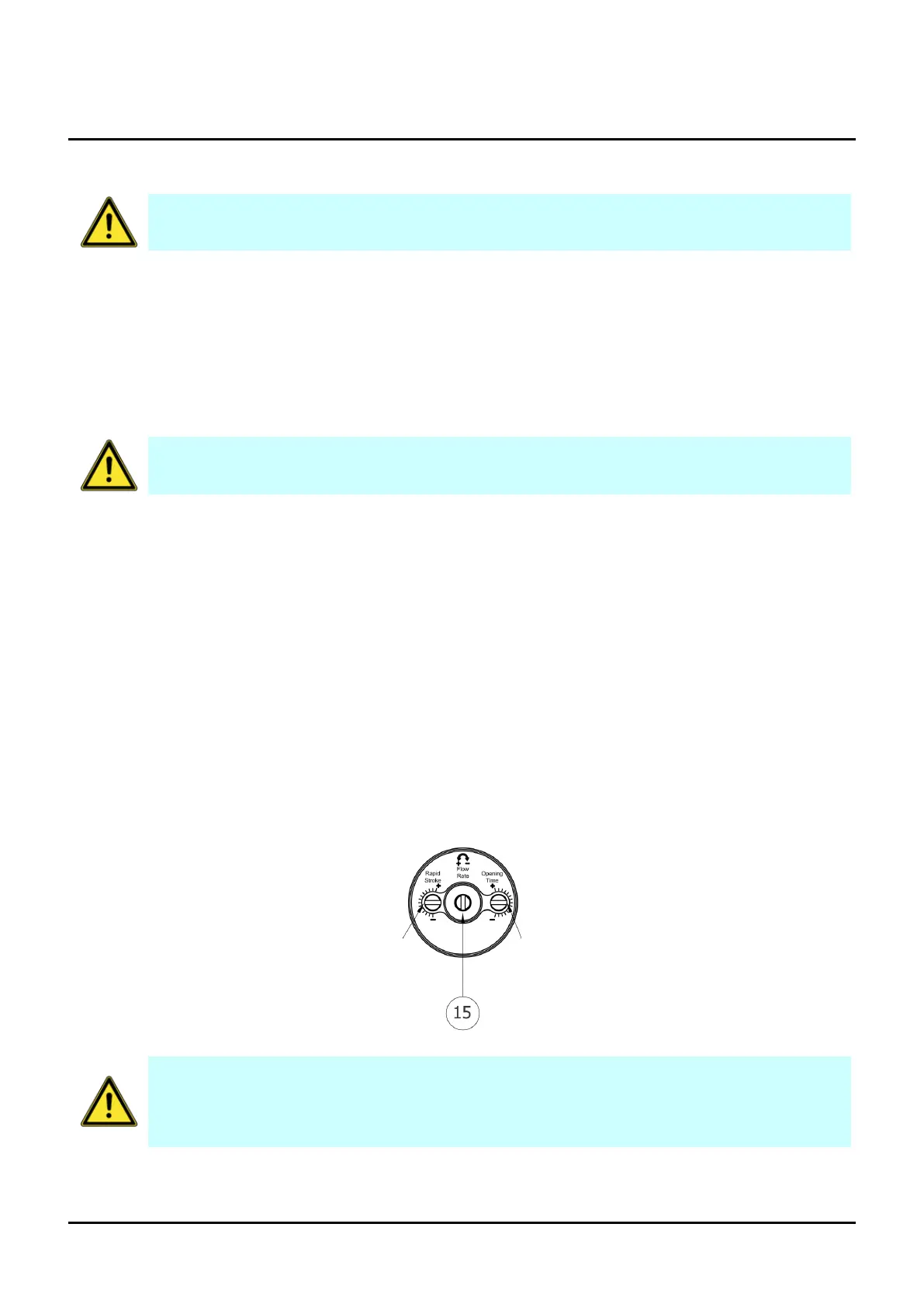

11. Adjust the gas pressure using the control valve (V2), which must be at 15/20 mbar. To adjust the

working pressure, close the whole valve (V2) using the screw on the head (15), and open 2 turns

(the units are already calibrated at the factory with a pressure of 20mBar) and check the flame

status, which must not reach the wall of the dehumidifier.

WARNING! All starting operations of these gas units must be carried out by qualified

personnel, suitable for operating on this type of equipment. Incorrect regulation of the gas

pressure causes malfunctioning in the system and damage to the dehumidifier (burning,

overheating of components, risk of flammability, etc.).

Loading...

Loading...