APPENDIX A-14 Manual 0-2962

APPENDIX 6: CUTMASTER 151 SYSTEM DATA

(HAND AND MACHINE TORCH)

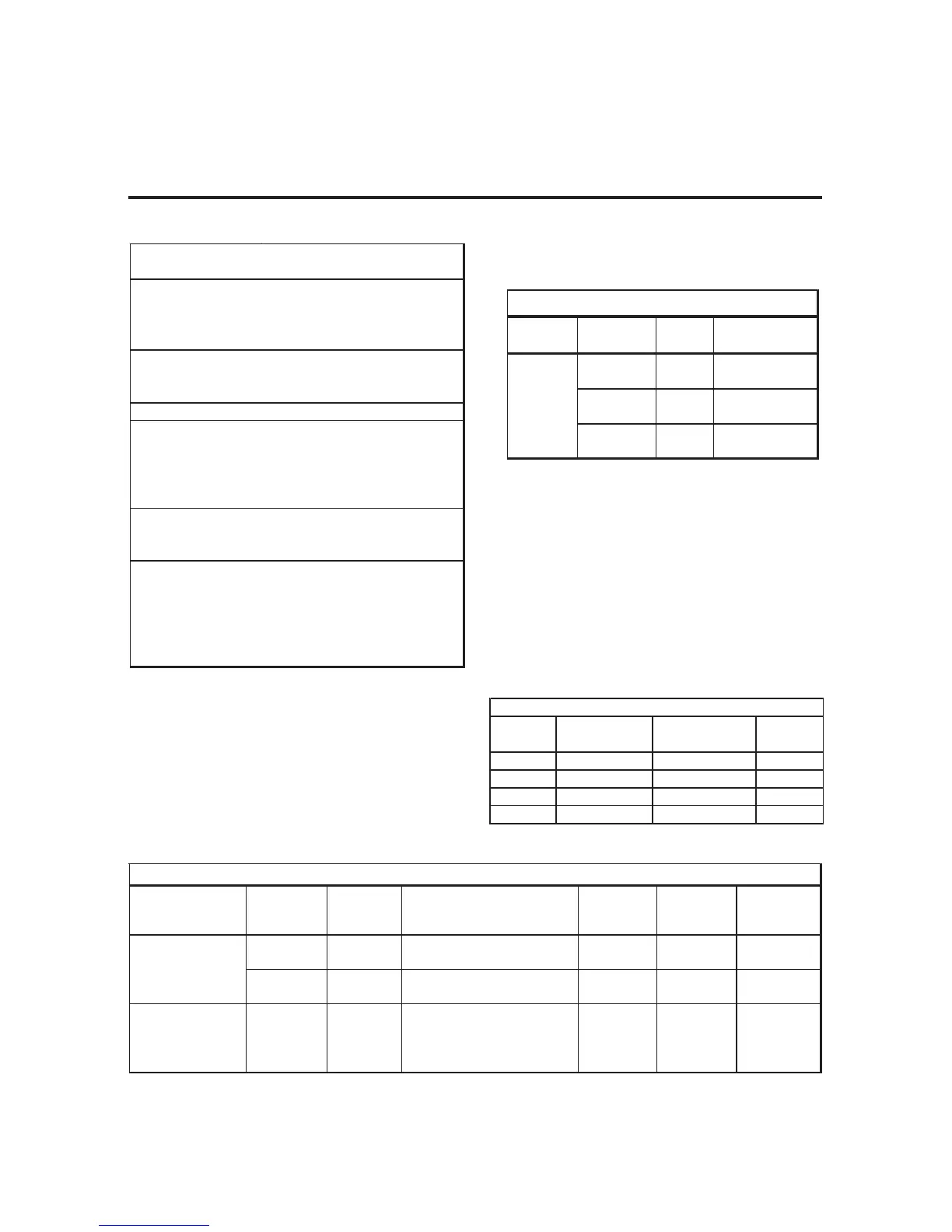

Cut Quality on Various Materials and Thicknesses

The following table defines the cut quality on vari-

ous materials and thicknesses:

Cut Quality on Various Materials

Material Type of Type of Cut

ThicknessMaterialGas Characteristics

Gage

to

Air

Air

Air

Good - Excellent

Good

Good

Carbon Steel

Stainless

Aluminum

1.5 inch

( 38 mm )

Description of Cut Characteristics:

Excellent - Minimum bevel (0 - 4°), minimum kerf (2

x tip orifice diameter), little or no dross,

smooth cut surface.

Good - Slight bevel (0 - 10°), slightly wider kerf (2-1/2

x tip orifice diameter), some dross (easily re-

moved), medium - smooth cut surface, slight

top edge rounding.

Cutting Range

Material Most Metals

Up to 1-1/2 inch / 38 mm

Speed11 ipm / 0.28 mpm

Pierce Rating

Material Carbon Steel

Thickness1/2 inch / 12.2 mm

Transfer Distance

3/8 inch / 9.5 mm

Gouging

Width1/4 inch - 6.3 mm (min)

Depth3/16 inch - 4.8 mm (min)

Number Passes Single

Speed20 ipm / 0.5 mpm

Bevel Cut Capability

Degrees0° to 45°

Material Thickness3/4 inch - 19 mm

Gas Requirement

Type GasAir

Operating Pressure 70 psi / 4.8 bar

Max Input Pressure 125 psi / 8.6 bar

Cutting & Gouging

Total Flow

490 scfh / 231 lpm

idth

Tip A 40 Amps Max. ShallowNarrow

Tip B 40-100 Amps Deep Narrow

Tip C40-100 Amps Moderate Moderate

Tip D40-100 Amps Shallo

ide

Gouging Profiles

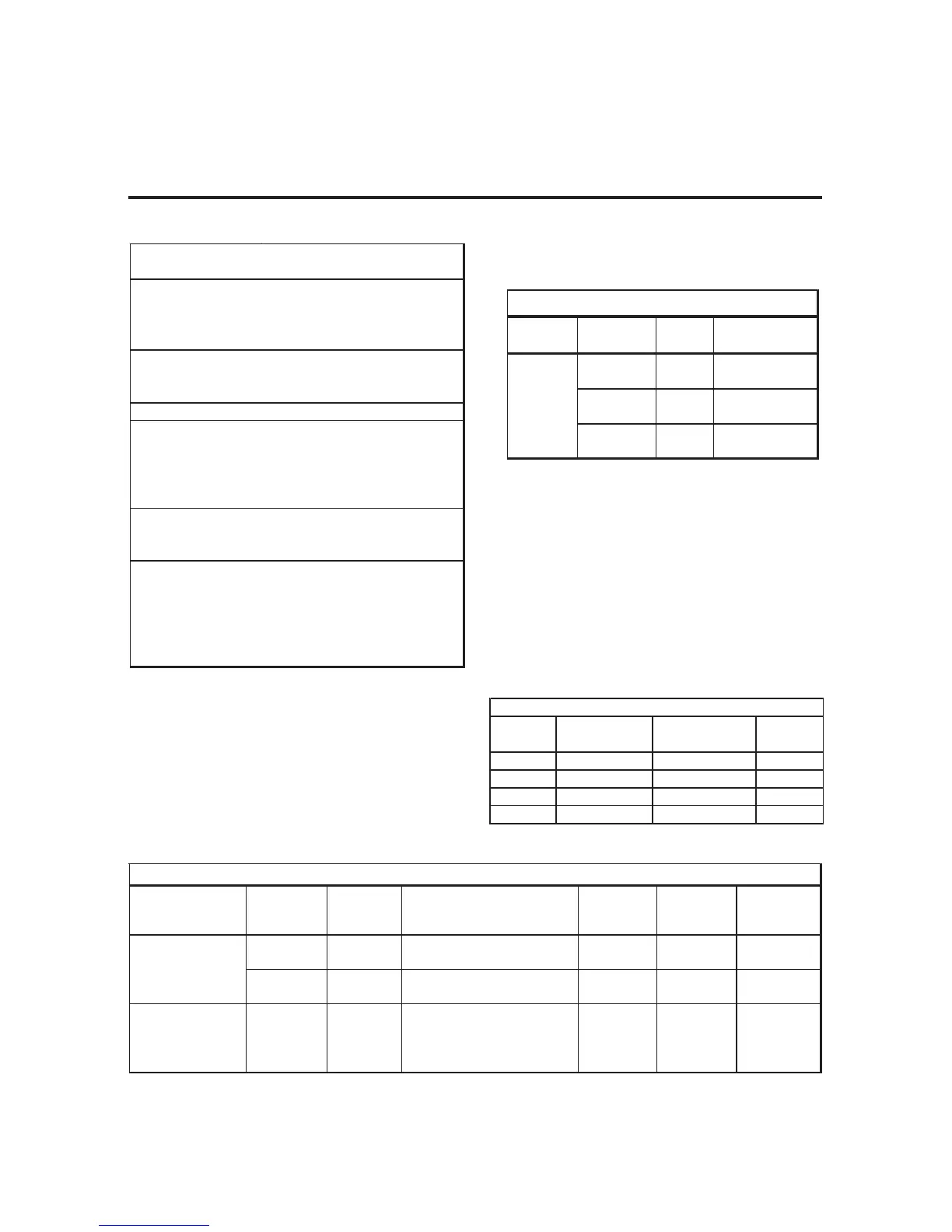

ApplicationElectrode

Start

Cartridge

Tip

Shield

Cup Body

Shield Cap

or Deflector

Shield Cup

9-8215 9-8213 9-8212 (100A) None None 9-8218

9-8215 9-8213 9-8212 (100A) 9-8237

9-8239 or

9-8243

None

Gouging9-8215 9-8213

Tip A: 9-8225 (40A Max)

Tip B: 9-8226 (40-100A)

Tip C: 9-8227 (40-100A)

Tip D: 9-8228 (40-100A)

9-8237 9-8241 None

SL100 Machine Torch Consumables for 100-Amp Power Supply

Standoff Cutting

Loading...

Loading...