15

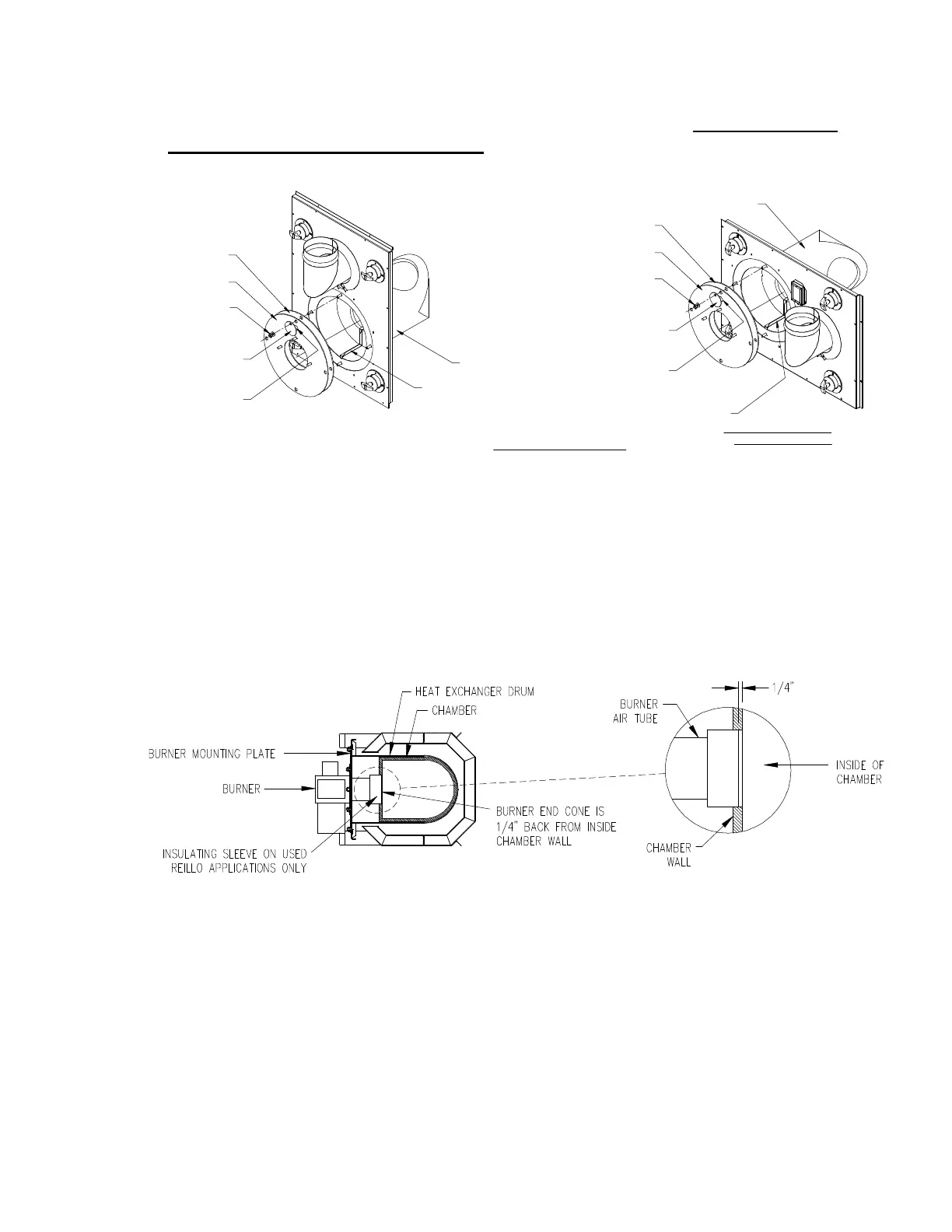

COUNTERFLOW

CHAMBER RETAINER

FR ONT FLU E MODELS S HOWN

SHOWN WI T H WARM AIR

OUT LET ON L EFT END

HORIZONTAL

OVERFIRE DRAFT

ACCESS COVER

OVERFIRE DRAFT

ACCESS PORT

NUT & WASHER

(4) PLACES

BURNER MOUNTING PLATE

BURNER MOUNTING

PLATE GASKET

COMBUSTION CHAMBER

CHAMBER RETAINER

OVERFIRE DRAFT

ACCESS COVER

OVERFIRE DRAFT

ACCESS PORT

NUT & WASHER

(4) PLACES

BURNER MOUNTING PLATE

BURNER MOUNTING

PLATE GASKET

CHAMBER RETAINER

COMBUSTION CHAMBER

chamber during shipping and helps to maintain insertion depth. DO NOT remove

this retainer when installing burner. (Refer to Fig.3).

Fig. 3: Burner Mounting Plate for Counterflow and Horizontal Installations

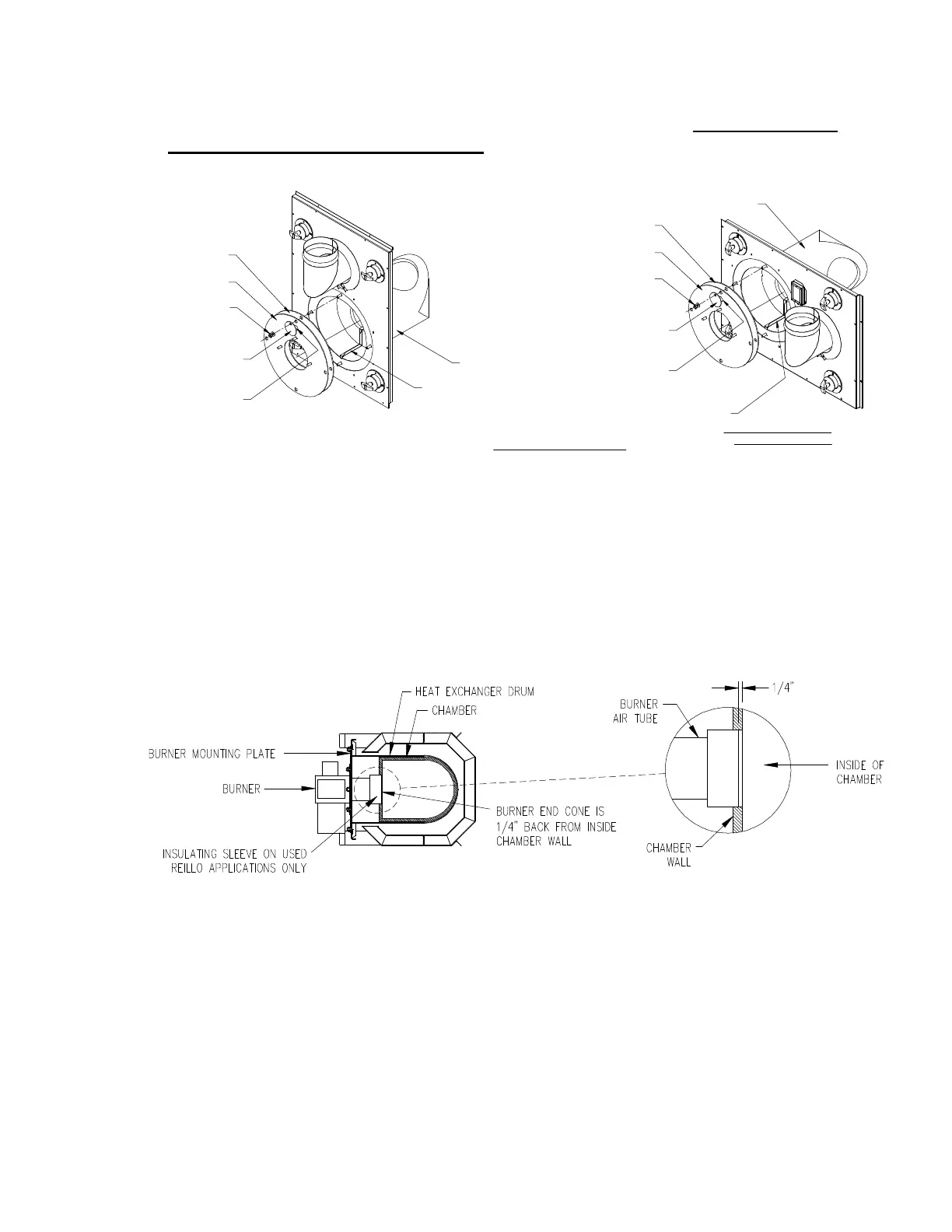

When mounting the burner, (Fig 4) do not allow the burner tube or end cone to

physically touch or protrude into the chamber, as excess heat transfer could

result in destruction of the tube, end cone or both. The burner tube/end cone is

properly positioned, when the end is ¼ inch back from the inside surface of the

combustion chamber wall. A fiber insulating sleeve is provided with the Riello

BF3 Burner.

Fig. 4: Burner Insertion Illustration (Top view)

The oil burner provided with this furnace requires initial inspection, set-up, and

proper adjustment. Refer to this manual and the oil burner manufacturer’s

operating instructions for detailed information on the following items.

Initial firing of burner

Adjusting the burner combustion air

Adjusting the fuel pump pressure

Setting the draft control

Loading...

Loading...