14

8. As a final step in the installation, the appliance must be adjusted to deliver a temperature rise within

the range of 50° to 80°F. Adjust the blower motor speed to obtain a temperature rise within the

acceptable range. The required blower speed will depend on the airflow resistance of a supply and

return air duct systems.

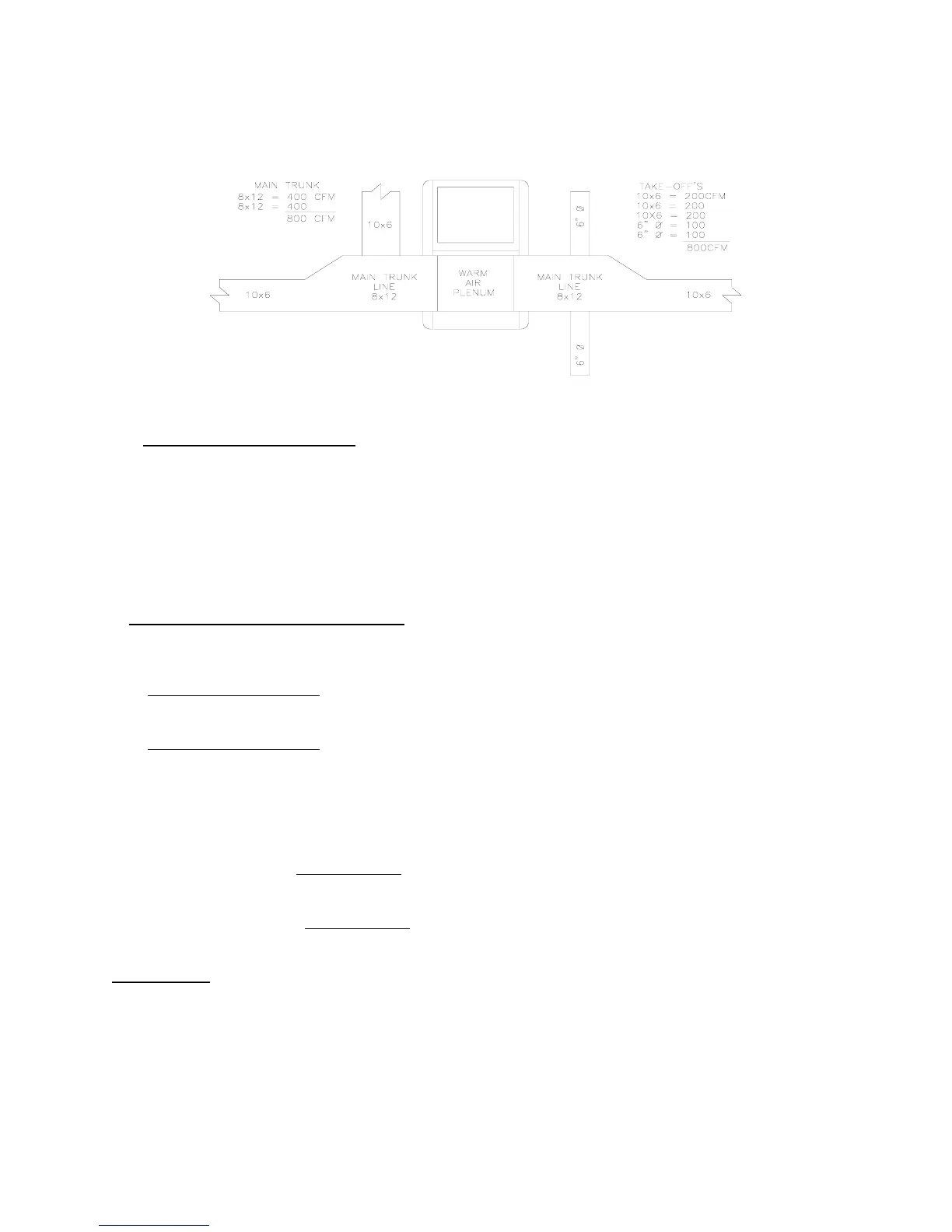

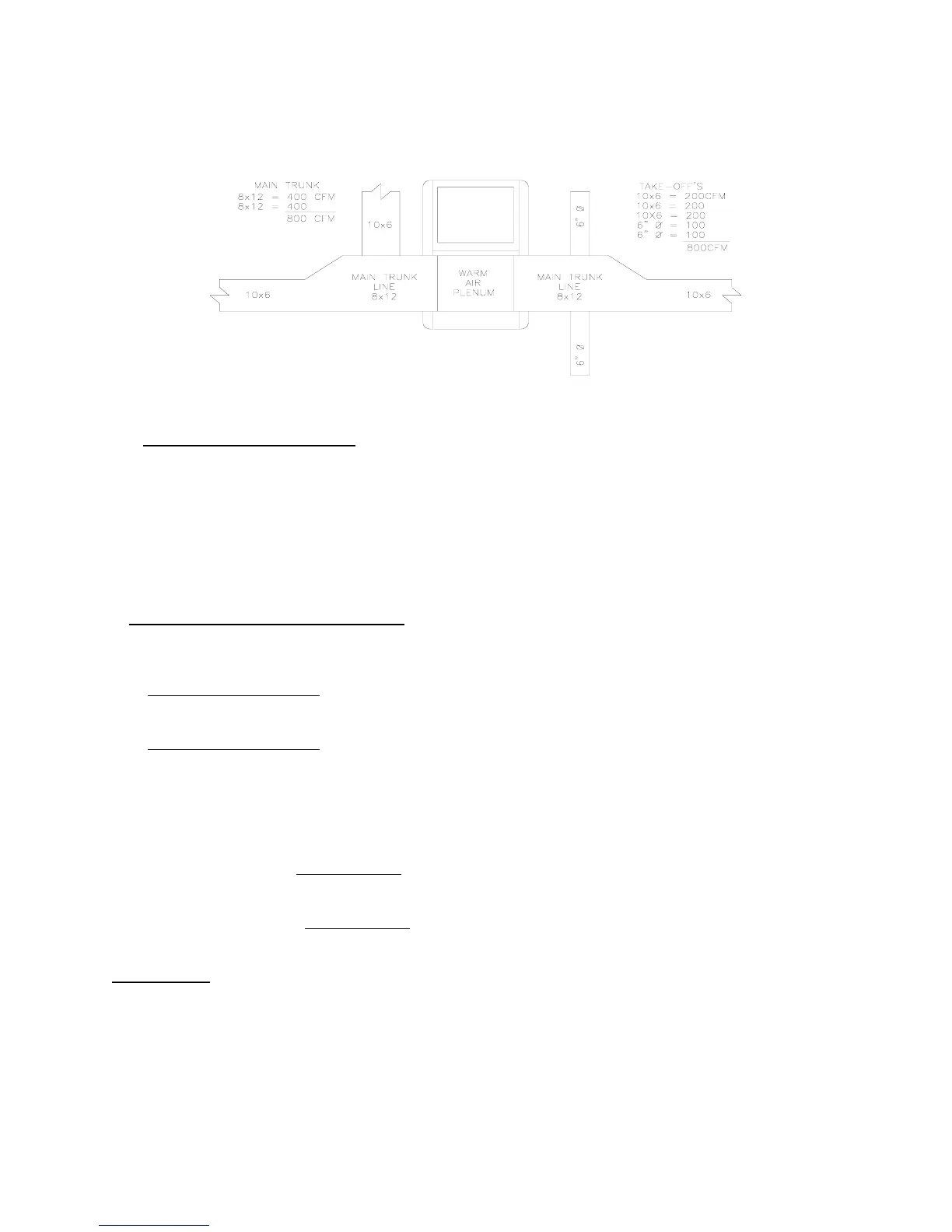

Fig. 9: Supply air duct sizing Example

The RETURN AIR DUCT SYSTEM

should equal the warm air duct system in airflow capabilities.

NOTE: When a return register is located in the same room as the furnace, the register must be at least 20

feet away from the furnace.

SIZING THE DUCT WORK FOR A COMBINATION HEATING AND COOLING SYSTEM:

Two formulas must be used in determining the CFM requirements of a combustion heating and cooling

system.

1. HEATING CFM:

HEAT OUTPUT OF FURNACE (BTUH)

1.1 X TR (TEMPERATURE RISE, °F) = HEATING(CFM)

EXAMPLES:

A. 110,000 BTUH OUTPUT

1.1 X 85°F TR = 1176 CFM FOR HEATING

B. 110,000 BTUH OUTPUT

1.1 X 70°F TR = 1429 CFM FOR HEATING

2. COOLING CFM: 400 CFM X COOLING TONNAGE (12,000 BTUH PER TON)=AIRFLOW FOR

COOLING(CFM)

EXAMPLES:

A. 400 CFM X 3 TON (12,000 BTUH)

= 1,200 CFM FOR COOLING

1TON

B. 400 CFM X 2.5 TON (12,000 BTUH)

= 1,000 CFM FOR COOLING

1 TON

IMPORTANT:

SIZE THE DUCT SYSTEM FOR THE LARGER OF THE TWO AIRFLOW

REQUIREMENTS.

Loading...

Loading...