31

Appendix C: Troubleshooting Tips For Reliable Electrical Heat Trace Performance

Troubleshooting Tips

Troubleshooting tips are provided here as a beginning point in correcting start-up issues and clearing out

alarm and trip events.

High Temperature Reading/Alarm

The following summarizes some of the possible causes and solutions for heat tracing high temperature alarms.

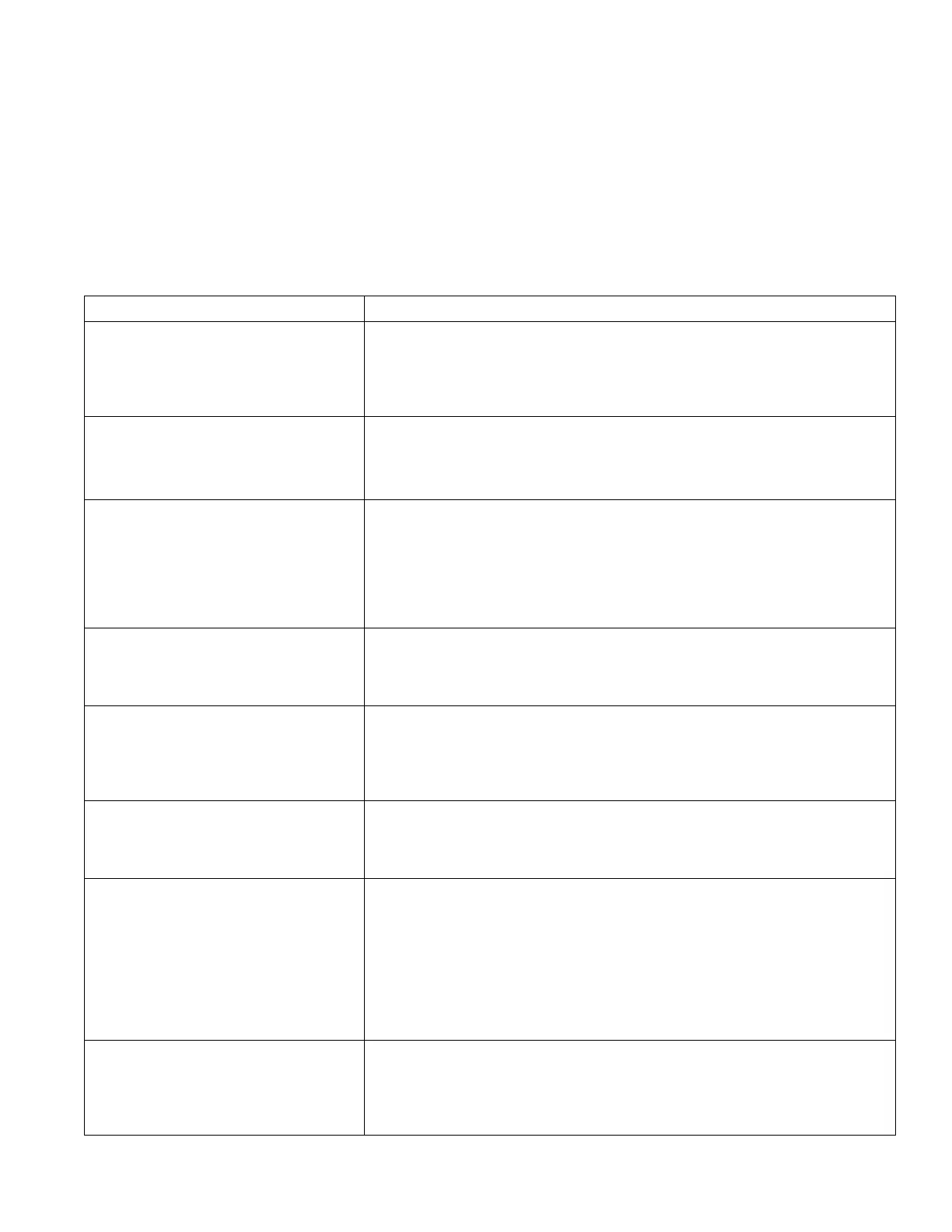

Possible Cause Recommended Solutions

Temperature of product in process

line is above alarm set point or the

expected reading due to events other

than heat tracing—high processing

temperatures, steam-outs, etc.

Let process return to normal condition or adjust alarm set point (if

approved by project engineer) to allow for this processing condition.

High alarm setting programmed or

expected reading did not consider

natural temperature overshoot

associated with the control scheme.

Move control set point down to allow for overshoot or raise the high

temperature alarm set point (if approved by project engineer). It may also

be possible to decrease the control band on the control circuit or adjust

the type of control from on-off to proportional.

Improperly located RTD sensor. Is the RTD sensor installed next to a heated tank or a steam jacketed pump

that might cause a higher than expected reading? Is the RTD sensor on

the heater itself? Move the RTD sensor to location more representative of

the majority of the piping. Is the sensor location representative for properly

controlling under all flow scenarios? Review location of the RTD(s) with

respect to the known process flow patterns which occur and change as

appropriate.

Wrong insulation size, type, or

thickness on all of the line being

traced.

Measure circumference of insulation, divide by π, and compare to

insulation diameter charts for proper over sizing. Check insulation type and

thickness against design specification. Replace insulation or review system

design for alternate operating possibilities.

Wrong insulation size, type, or

thickness on part of the line being

traced.

The insulation system should be as specified in the design for the entire

circuit being traced. Having a lower heat loss on one part of the circuit and

higher heat loss insulation on the other part of the circuit (perhaps where

the RTD sensor is) will result in the better insulated line being too hot.

Redo the insulation to assure uniformity and consistency.

Damaged RTD temperature sensor. Disconnect RTD sensor and measure resistance. Compare to resistance

tables for corresponding value of temperature. Compare to pipe or

equipment temperature known by another probe or sensor. If different,

the RTD sensor may need replacement.

Heat tracing over designed in

heat output and or/ due to cable

availability or natural design selections

available. This can result in higher

than expected temperatures due to

overshoot (especially when used with

on-off control mode). This can also

occur in an ambient sensing control

modes.

Review design as well as installation instructions. Check heat tracing

for presence of proper current. Since replacing the circuit may not be a

desirable option here, the first approach should be to adjust the control

method which the control system has been configured in.

Heat tracing circuits are mis-wired

such that the RTD for circuit 1 is

controlling circuit 2, etc.

Trace and recheck field and panel wiring. Use circuit "turn-on " and

"turn-off" technique or disconnect RTD’s one at a time to see if the proper

RTD failure alarm occurs on the right circuit. Let process return to normal

condition or adjust alarm set point (if approved by project engineer) to

allow for this processing condition.

Loading...

Loading...