17

Section 4: Genesis Controller Control

Options and Examples

The Genesis Controller system allows different options

for heat trace control.

• Line sensing (RTD Sensor on pipe-wall and requires

consideration of process flow.)

• Ambient Sensing (“On-off” or Ambient Proportional

Control)

The most energy efficient control mode is to use one

(or more) line sensing RTD’s for each heat trace circuit.

For winterization, ambient sensing is the most

common because it represents the fewest electrical

circuits and lowest installed cost. See Figure 2, below.)

It is also the least accurate method of control; all

connected heaters are energized when the ambient

temperature falls below the control set-point.

• Ambient “On-off” control delivers 100% power

whenever energized, the least energy efficient.

• Ambient Proportional Control (APC with Solid State

Relays, or APC-M with Mechanical Relays) delivers a

percentage of power determined by the difference

between the desired maintain temperature and

the measured ambient temperature at any time.

(More energy efficient than Ambient “On-Off”, but

not as efficient as line sensing.)

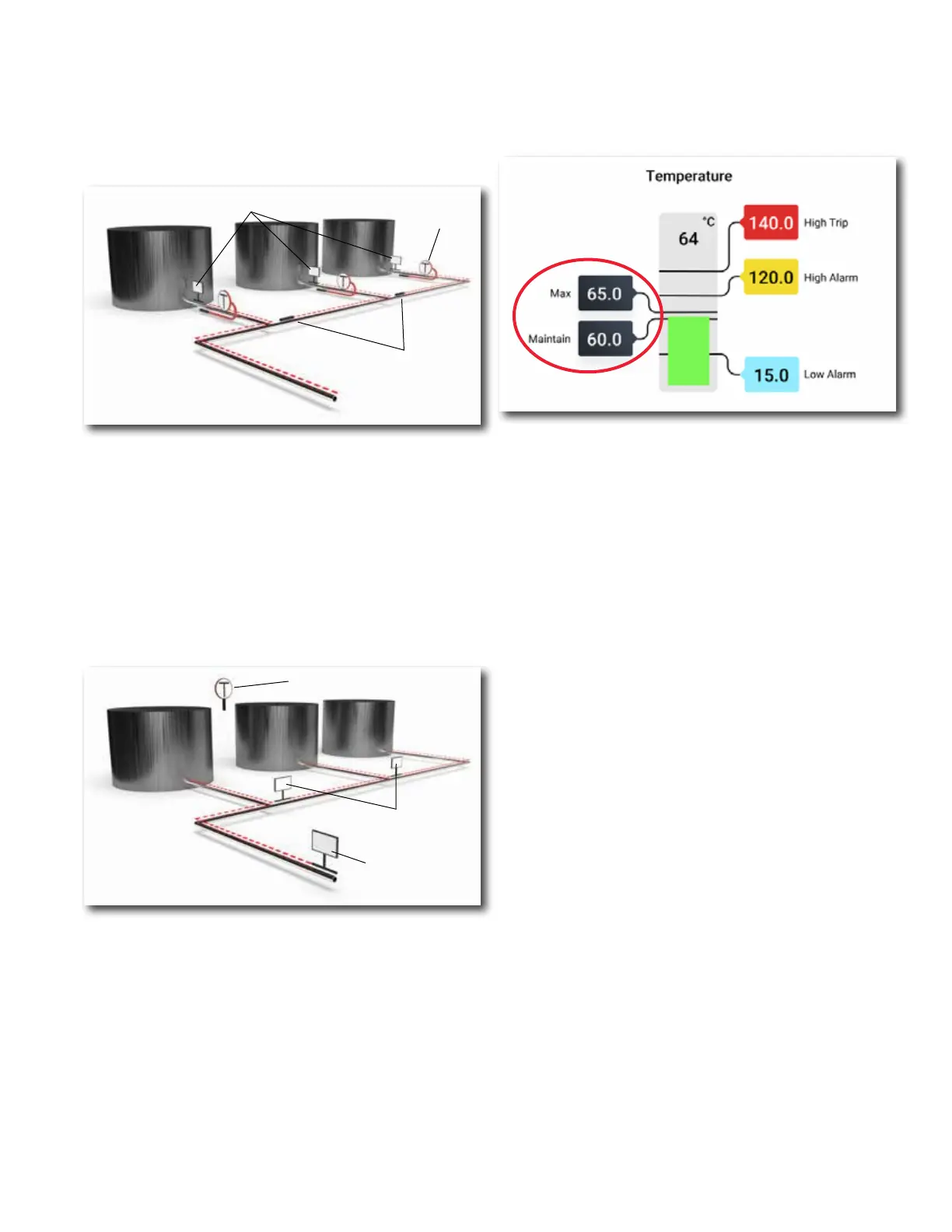

4.1: Line Sensing Control

When the RTD is directly sensing pipe-wall surface for

control, the key parameters are “Maintain Temperature”

at which the heat trace is energized or turned on. The

“Max” temp setting is where the heat trace will be

de-energized, or turned off. The difference between

these control settings defines the “Control band” (aka

“control differential” or dead-band)

The line sensing RTD(s) temperature is read by the

Genesis Controller for heater control for low and high

temperature alarms. (A “high-high” temperature

setting with circuit “trip” option is also determined

from the line sensing RTD(s).) When configured

with more than one RTD sensor, Genesis Controller

displays and controls from the lowest temperature

RTD reading, and alarms are triggered from the

highest.

4.2: Ambient Sensing Options

For the Genesis Controller system, (and its

predecessor the TCM18), “Ambient Proportional

Control” or APC, refers to a “time proportioning”

function for saving energy when compared to

Ambient Sensing “On-Off” temperature control. As an

example, if a given situation calls for 50% power, then

the controller cycles on and off 50% of the time to

achieve this energy delivery.

APC mode is less energy efficient than line-sensing

control, but generally allows fewer heating circuits

and longer circuit lengths.

Ambient Proportional Control can be successfully

used for maintaining elevated process temperatures

as well. This can reduce the number of heating circuits

by allowing longer heating circuits, but will not be

as energy efficient as line-sensing RTD temperature

control .

The APC method has traditionally utilized solid

state control relays capable of rapid cycling during

operation. By expanding the cycle time to 20 minutes

between “on” and “off”, however, mechanical relays

can be used. This is referred to as APC-M.

Heater Relay Type

Control relays for Genesis Controller can be either

solid state or mechanical switching relays. The Genesis

Controller control output is a nominal DC voltage of

24 Vdc to drive the solid state or mechanical relays.

There are advantages and limitations of both relay

types. Consult your Thermon service provider if you

have questions.

Control Band

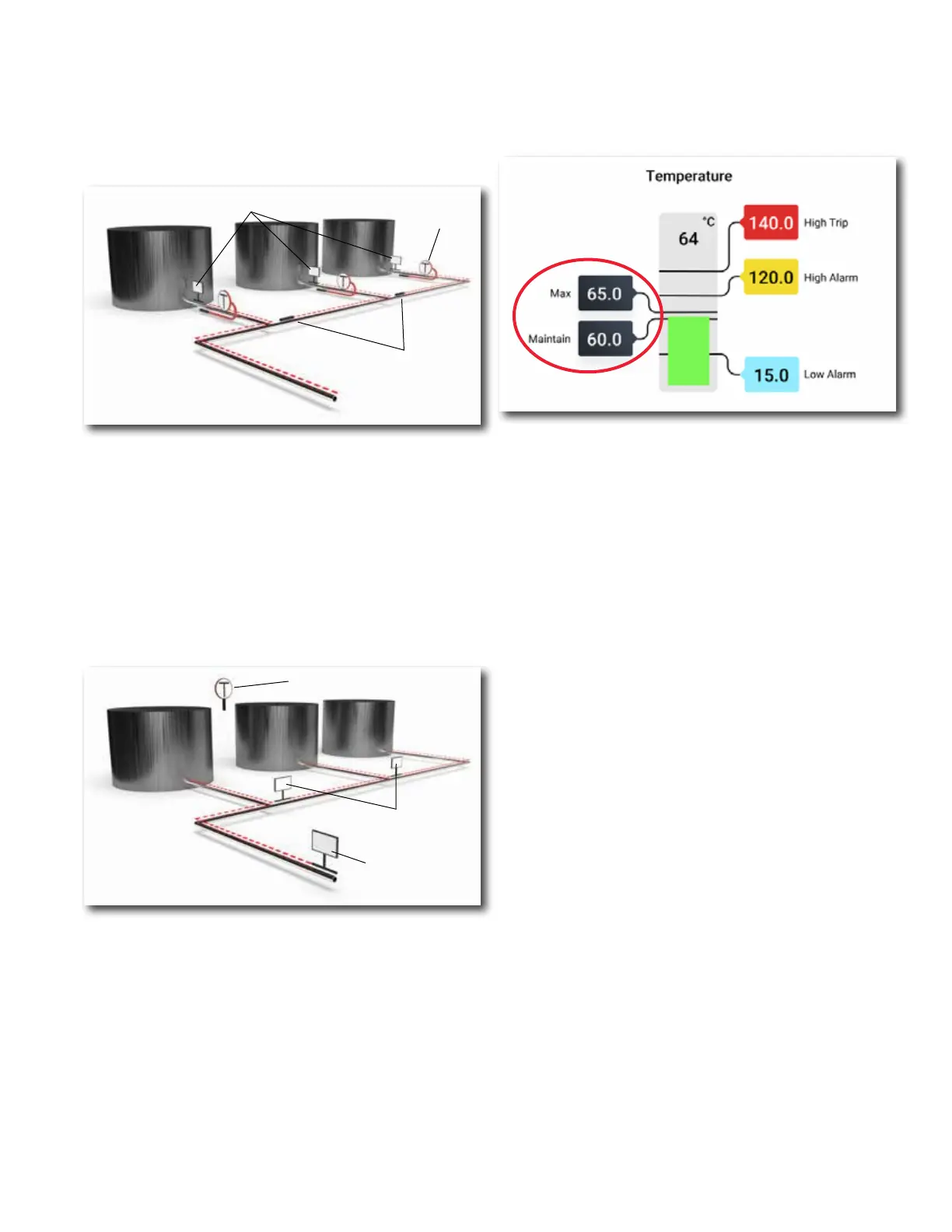

Ambient Sensing Control without concern for ow path

Splices

Thermostat

Line Sensing Control considering possible ow paths

Power Connections

End Terminations

Thermostat

Power Connection

Loading...

Loading...