Calibration & Measurement Module for OTKB/OTKBFM Chapter 5: Operation

TTN030035-D02 Page 10

Chapter 5 Operation

Before quantitative measurements can be performed with the optical tweezers system, it is necessary to

determine the factor to convert detector voltages to distances and to find the trap stiffness. Changing the trapping

laser power during this procedure will affect the calibration parameters. Therefore it often makes sense to run the

calibration sequence described below for various laser power settings. Further on, the distance of the laser trap to

the cover slip will affect the trap stiffness significantly. Again you can determine the calibration for different z-

positions using the positioning system of the stage. During an initial calibration make sure that your trap is located

several microns above the cover glass. This can be achieved by moving a trapped bead towards the cover glass

until it contacts the glass and goes out of focus. The z-axis adjustment knob on the stage has micrometer

markings, which you can then use to move the trap away from the cover glass surface. If the bead is too close to

the wall, hydrodynamics effects or physical constraints with the coverslip will restrict the Brownian motion, while at

heights above 5 µm the optical trap loses its tight focus.

We assume that you have setup your tweezers system and aligned the detector to monitor the back focal plane of

the condenser. Further on you need to load a sample with a combination of stuck and freely diffusing

microspheres. See Section 5.3 for details.

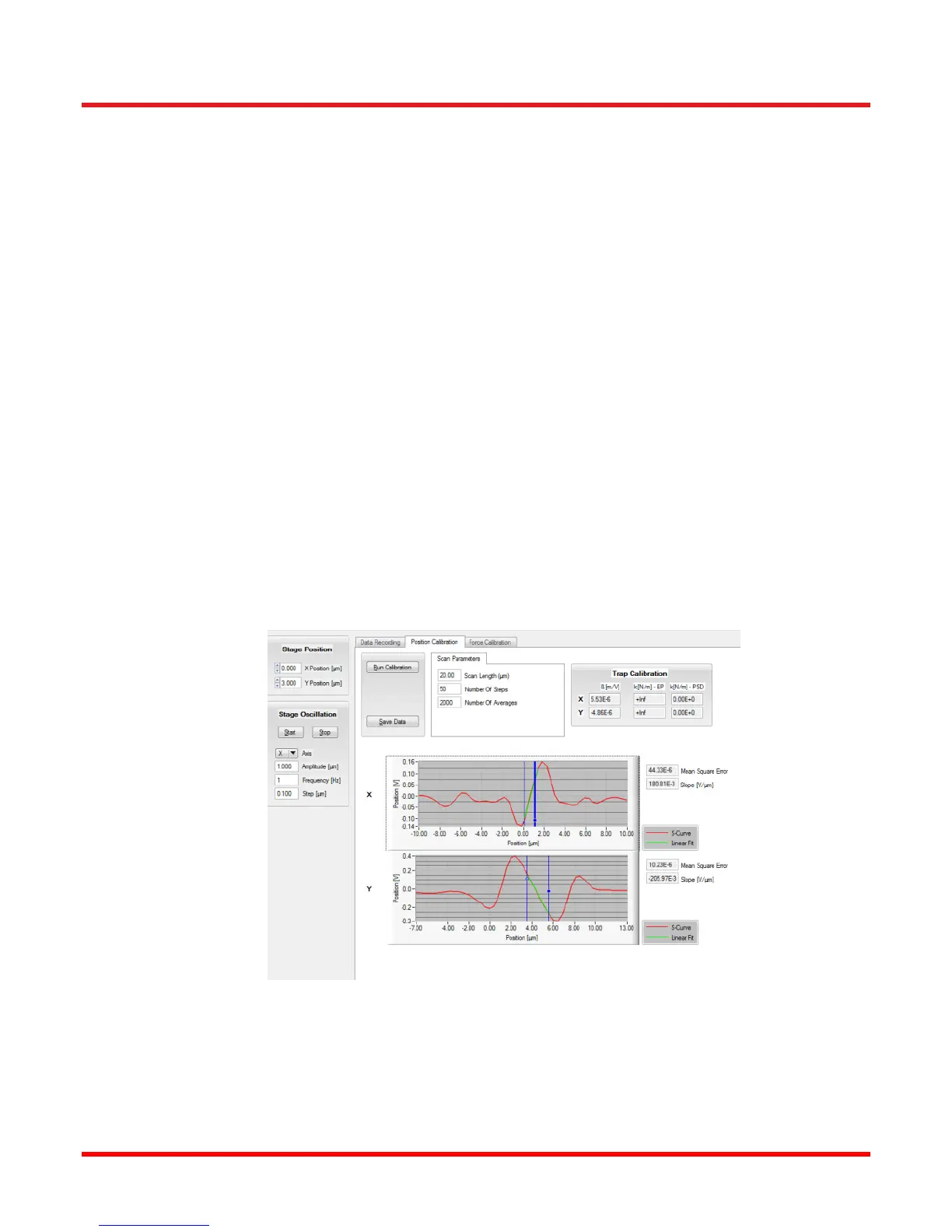

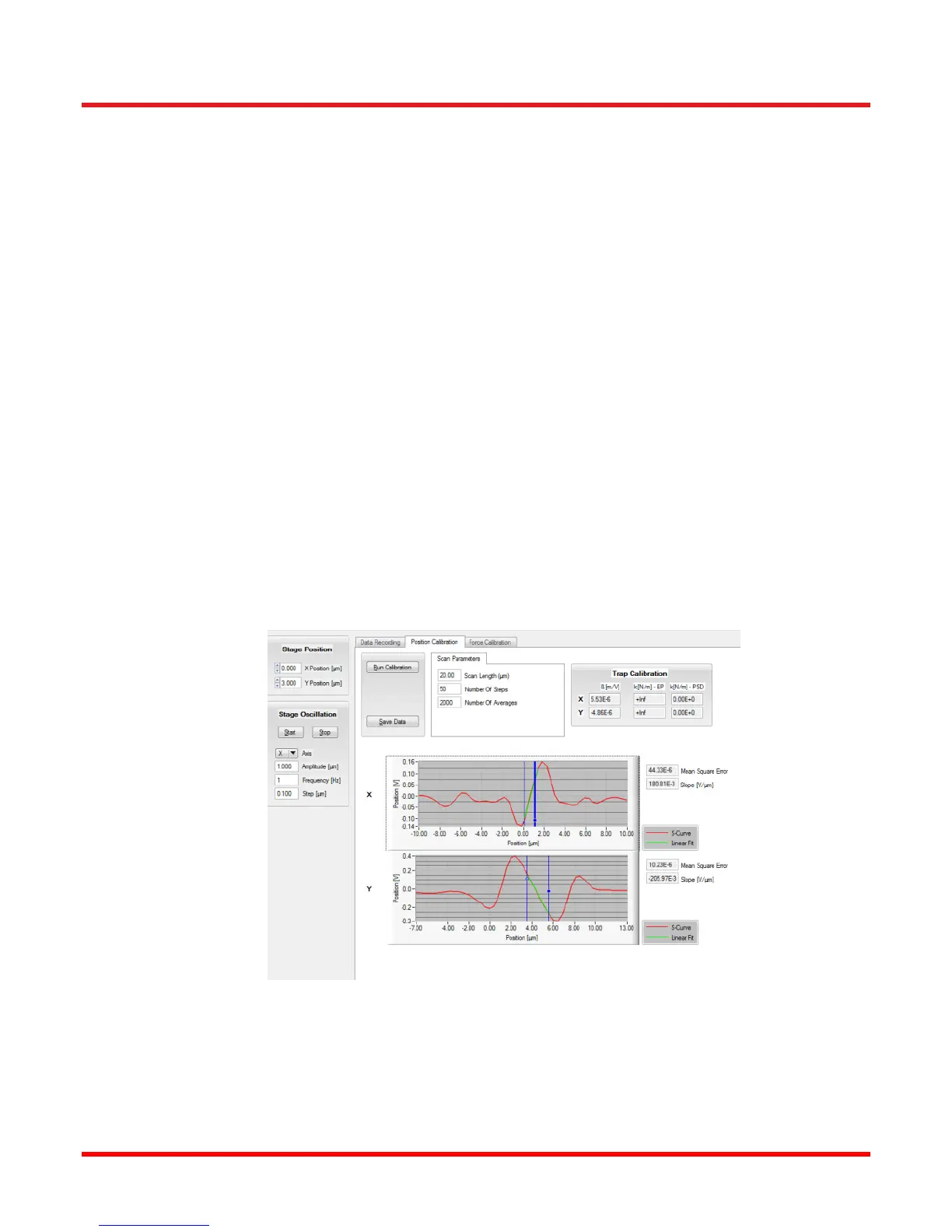

5.1. Position Calibration

When a bead is located close to the trap center a linear relationship exists between the quadrant detector voltage

and the distance of the bead to the trap center. To find the corresponding conversion factor we use a stuck bead

and move it across the trap at a constant speed. Plotting the detector voltage versus stage position a curve can

be fitted to the linear range, providing the conversion factor. A sample plot is shown in Figure 7 below.

1. Move the sample stage until you see a free bead on your camera image. Enable the trapping laser and

trap the bead. Mark the position on your monitor, e.g. using a small piece of tape. Disable the laser to

release the bead.

Figure 7 Example Position Calibration Plot Showing Fit to the Linear Range

2. Find a stuck bead and move it to the position marked as the trap position on the screen.

3. Select the “Data Recording” Tab and click on “Start Tracking”. You will see a curve similar to the example

shown in Figure 8 on Page 13.

Loading...

Loading...