TIMBERWOLF

TW 230DHB

11

The no stress unit controls the feed rate of the material going into the chipping chamber. When the rotor

speed is below the predetermined level the no stress unit will not allow the feed rollers to work in the

forward direction. When the rotor speed rises above the predetermined level the feed rollers will start

turning without warning.

Push the

RED SAFETY BAR. The rotor will still be turning, the engine must be powered down to stop

the rotor. Turn off the engine ignition key.

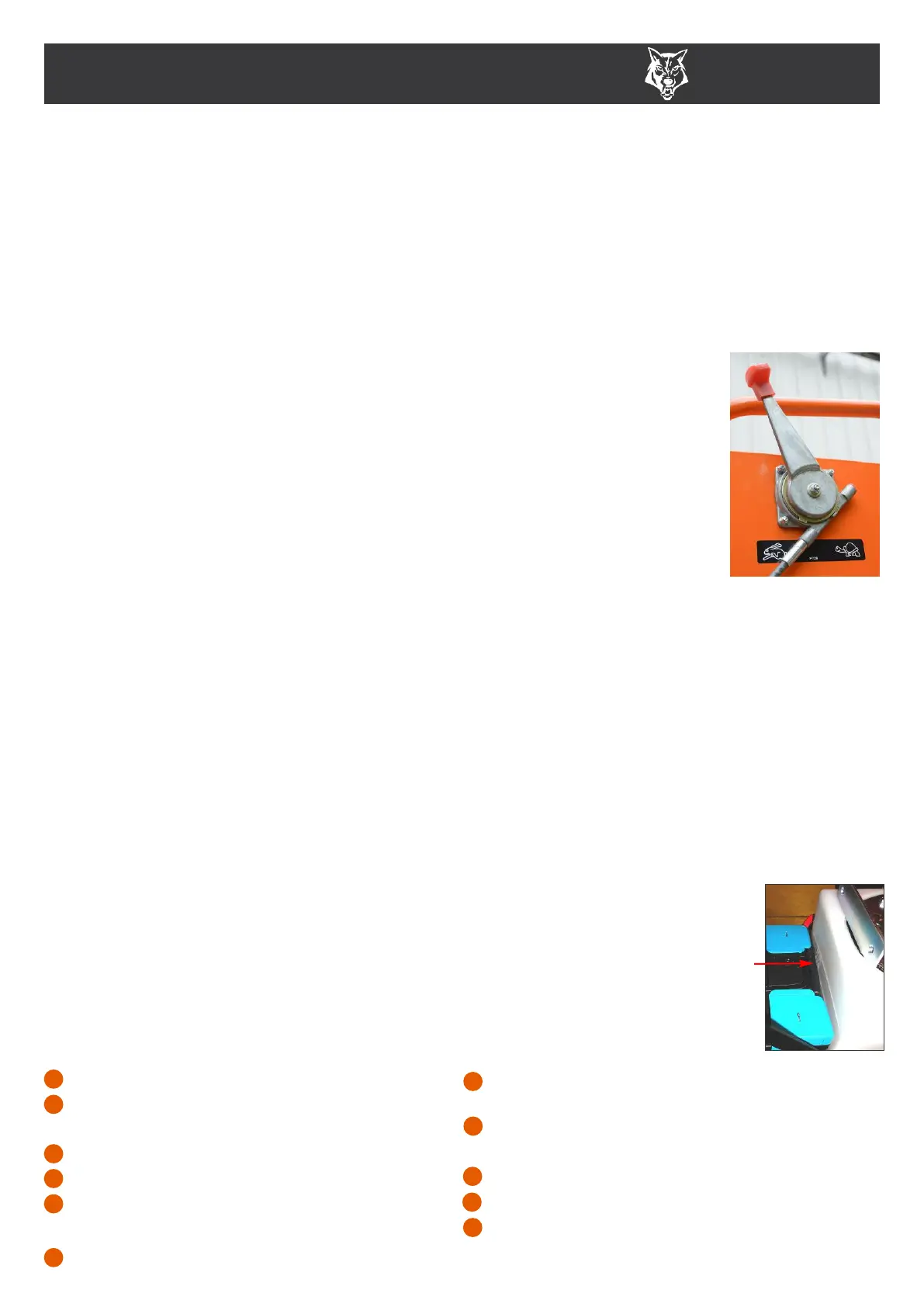

For operator convenience the engine speed control is mounted on the funnel.

Always start the engine with the lever in the ‘slow’ (idle) position. With the throttle

lever in the ‘fast’ position the machine is ready to chip. It MUST be fully pushed to

the left to achieve a suitable working speed. If no wood is to be chipped for a few

minutes the throttle should be returned to the ‘slow’ (idle) position.

LOCATE the machine on firm level ground.

CHECK machine is well supported and

cannot move.

CHECK jack stand is lowered and secure.

CHECK all guards are fitted and secure.

CHECK the discharge unit is in place and

fastened securely.

CHECK discharge tube is pointing in a safe direction.

CHECK the feed funnel to ensure no objects

are inside.

CHECK feed tray is in up position - to prevent

people reaching rollers.

CHECK controls as described on page 12.

CHECK (visually) for fluid leaks.

CHECK fuel and hydraulic oil levels.

For parts location see diagrams on pages 4 & 5.

AUTO CONTROLS

EMERGENCY STOPPING

EN

GI

N

E

C

ON

TROLS

HYDRAULIC OIL LEVEL INDICATOR

DAILY CHECKS BEFORE STARTING

BLADE WEAR

The most important part of using a wood chipper is keeping the cutter blades sharp. Timberwolf

chipper blades are hollow ground to an angle of 40 degrees. When performing daily blade checks

ensure blade edge is sharp and free from chips, if there is any evidence of damage, or the edge is “dull”

change the blade(s). The TW 230DHB is fitted with 2 blades 135mm (5") long. They are 100mm wide

when new. A new blade should chip for up to 25 hours before it requires sharpening. This figure will

be drastically reduced by feeding the machine with stony, sandy or muddy material.

As the blade becomes blunt, performance is reduced. With increased stress and load on the machine

the chips will become more irregular and stringy. At this point the blade should be sent to a reputable

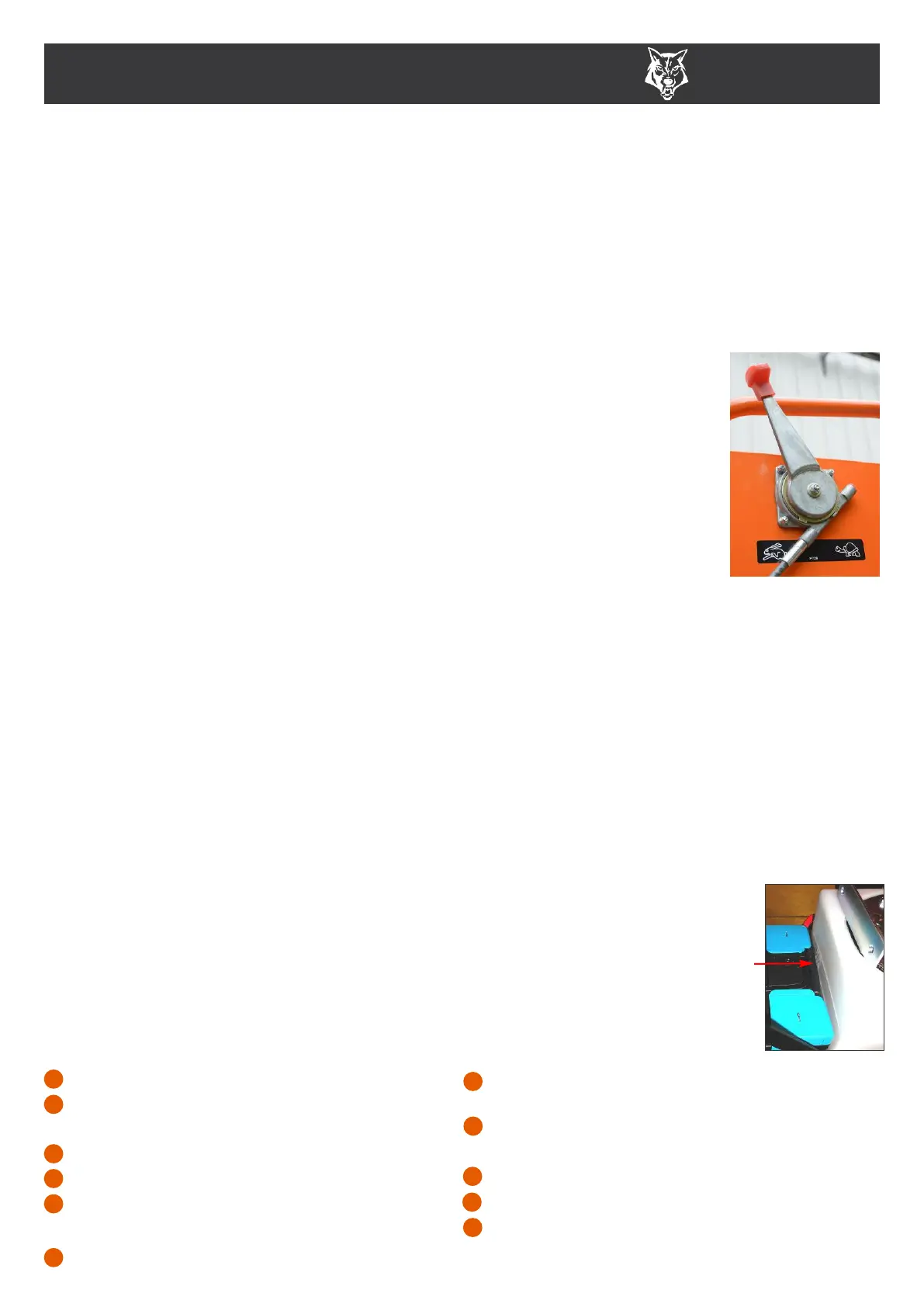

blade sharpening company. The blade can be sharpened several times in its life. A wear mark

indicates the safe limit of blade wear. Replace when this line is exceeded.

The machine is also fitted with a static blade (anvil). It is important that the anvil is in good condition

to allow the cutting blades to function efficiently. Performance will be poor even with sharp cutter blades

if the anvil is worn.

The oil level will be visible through the tank wall. It should be within the upper and

lower level marks.

FUEL LEVEL INDICATOR

The fuel level can be seen through the wall of the plastic tank.

OPERATING INSTRUCTIONS

Loading...

Loading...