English

2 ©TitanToolInc.Allrightsreserved.

Setup

Never attempt to assemble, change, or clean the gun, tip,

or tip guard without first relieving pressure from the spray

system. Follow the “Pressure Relief Procedure” in the

sprayer’s Owner’s Manual.

Always use a tip safety guard for added

protection against injection. Beware

that the guard alone will not prevent

injection. Never cut off tip guard! Always

engage gun trigger lock when the gun is

not in use. Before servicing equipment,

consult Owner’s Manuals and follow all

warnings.

Trigger lock in

locked position.

1. Setupthesprayer.Refertotheinstructionsin

thesprayer’sOwner’sManual.

2. Attachaconductiveorgrounded,airlessspray

hosetothematerialinletonthegun.Usingtwowrenches(oneon

thegunandoneonthehose),tightensecurely.

3. Withthetipguard,tipswivel,andpolemountothegun,start

thesprayer.Flushandpreparethespraysystemaccordingtothe

sprayer’sOwner’sManual.Inspectthespraysystemtomakesurethat

all ttings are secure and that there are no leaks.

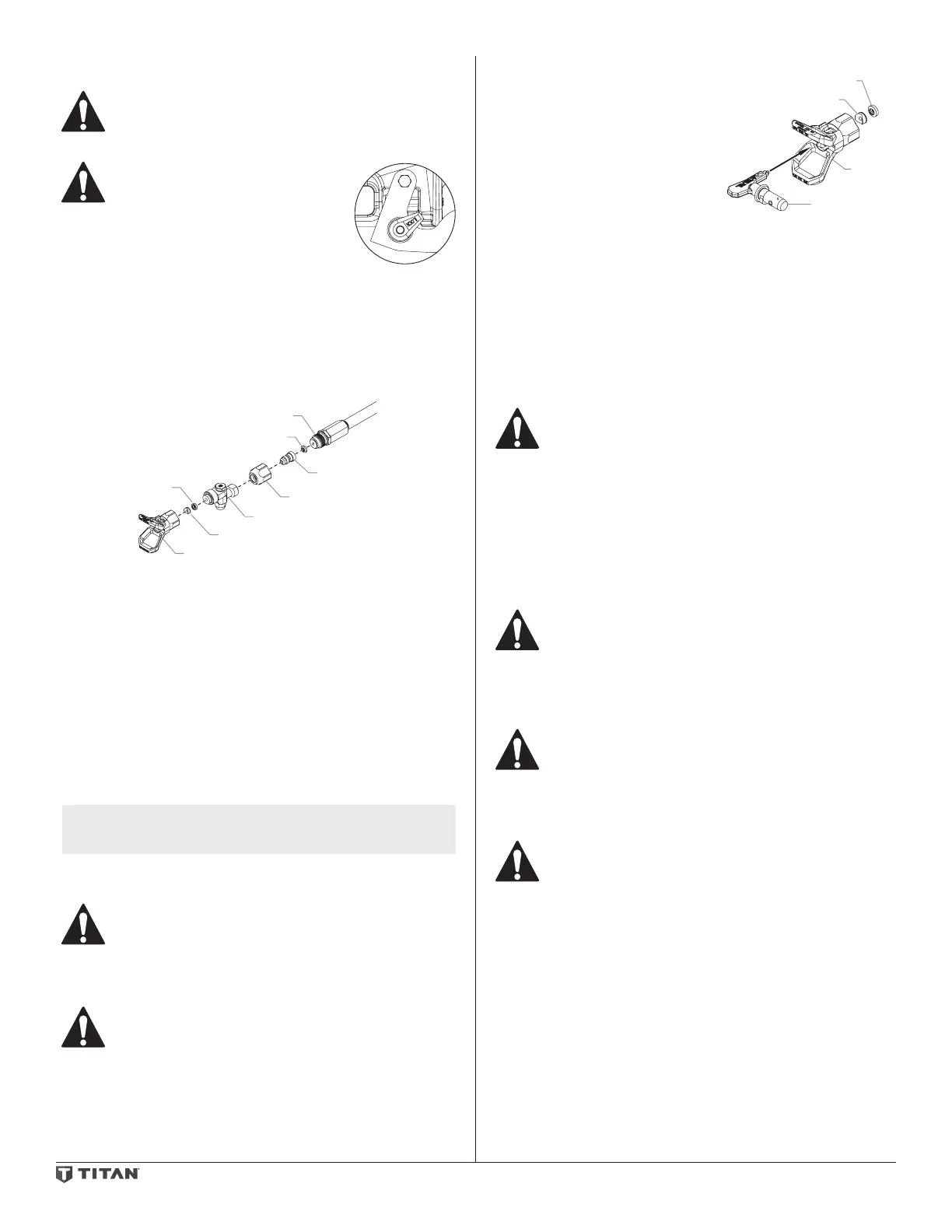

Diuser

Seal Washer

Tip

Seal

Pole Moun

Retaining Nut

Tip Swivel

Tip Seal Retainer

4. Performthe“PressureReliefProcedure”describedinthesprayer’s

Owner’sManual.

5. Placethesealwasherandpolemountoverthediuser,andsecurein

position using the retaining nut. Tighten securely using a wrench.

6. Threadthetipswivelontothepolemount.Tightensecurelyusinga

wrench.

7. Threadthetipguardontothetipswivel.Tightensecurelyusinga

wrench.

Operation

1. Insertthedesiredtipassemblyintothetipguard.

2. Startthesprayer.Refertotheinstructionsinthesprayer’sOwner’s

Manual.

3. Adjusttheuidpressureonthesprayeruntilthesprayiscompletely

atomized.Alwayssprayatthelowestpressurenecessarytogetthe

desired results.

NOTE: The spray tip determines the size of spray pattern and

coverage. When more coverage is needed, use a larger tip

instead of increasing uid pressure.

4. Operatethetriggerandusethesamesprayingtechniquesaswith

standardpistol-gripairlesssprayguns.

Use extreme caution when spraying with a extension pole.

Do not spray near power lines. Avoid all other over-head

obstacles.

Changing a Tip

Tipscanberemovedandreplacedeasilywithoutdisassemblingthegun.

Never attempt to change or clean the tip or tip guard without

first performing the “Pressure Relief Procedure.”

1. Performthe“PressureReliefProcedure”describedinthesprayer’s

Owner’sManual.

2. Removethetipfromtheslotonthetipguard.

3. Insertthenewtipintotheslotonthetipguard.Thearrowonthetip

handleshouldbepointingintheforwarddirectionforspraying.

Removing the Tip Seal and Tip Seal Retainer

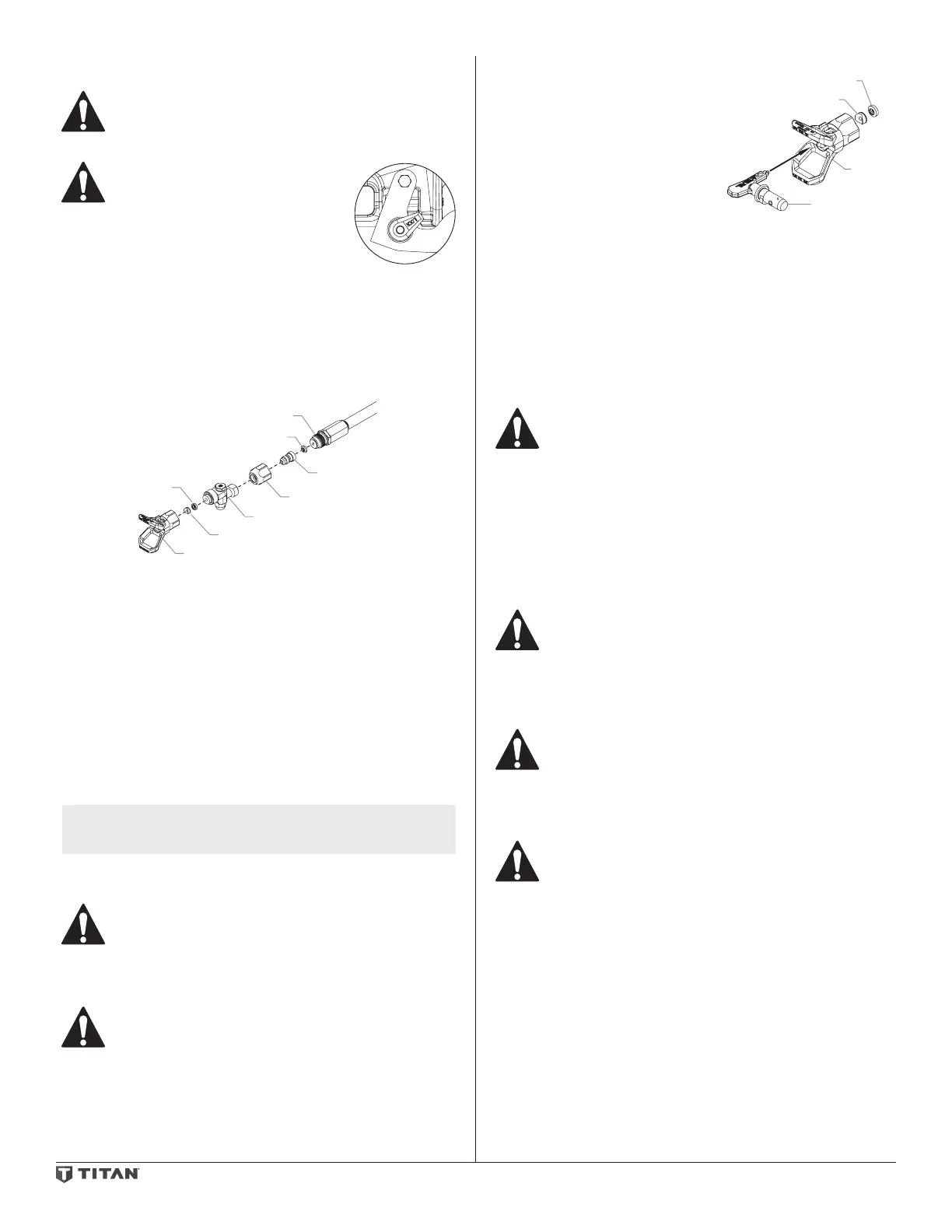

Tip

Guard

Tip

Tip Seal Retainer

1. Removethetipfromthetip

guard.

2. Insertthetiphandlethroughthe

front of the tip guard.

3. Pushthetipsealandtipseal

retaineroutthroughthebackof

the tip guard.

Identifying Tip Sizes

Toidentifytipsizes,usethefollowing

formula.A“517”tipsizewillbeusedin

this example.

Therstdigitmultipliedbytworepresentsthesizeofthespraypatternwhen

spraying12”awayfromtheworksurface:

5x2=10”spraypattern

Thesecondtwodigitsrepresentthediameteroftheoriceonthetip:

17=.017”orice

Cleanup

Maintainingacleangunisimportanttoensuretrouble-freeoperation.

Removethetipguard,tipswivel,andpolemount,andushthegunaftereach

use.Storeinadrylocation.Donotleavethegunoranyofitspartsinwater

or solvents.

Special cleanup instructions for use with flammable solvents:

• Alwaysushspraygunpreferablyoutsideandatleastonehose

length from spray pump.

• Ifcollectingushedsolventsinaonegallonmetalcontainer,

place it into an empty ve gallon container, then ush solvents.

• Areamustbefreeofammablevapors.

• Followallcleanupinstructions.

IMPORTANT: The sprayer, hose, and gun should be cleaned thoroughly

after daily use. Failure to do so permits material to cake, seriously

affecting the performance of the unit.

Always spray at minimum pressure with the tip guard, tip

swivel, and pole mount removed when using mineral spirits

or any other solvent to clean the sprayer, hose, or gun. Static

electricity buildup may result in a fire or explosion in the

presence of flammable vapors. Hold the gun firmly against a

metal container while flushing.

Maintenance

Follow all safety precautions as described in the Safety

Precautions section of this manual before proceeding.

Replacing/Servicing the Seal Assembly

Ifthespraygunleaksorspitsatthetipwhenthetriggerisreleased,theseal

assemblyisworn,damaged,ordirtyandmustbereplacedorcleaned.

Never attempt to perform maintenance on the spray gun

without first performing the “Pressure Relief Procedure.”

1. Disconnecttheairlesssprayhosefromthegun.

2. Placeonewrenchonthegunheadttingandanotherwrenchonthe

rear tting of the extension pole. Turn the entire extension pole to

unthreaditfromthegunheadtting.Makesurethettingonthe

extension pole does not move during its removal.

IMPORTANT: Do not try to remove either of the fittings on the extension

pole. Movement of these fittings will break the factory seal and cause the

gun to leak.

3. Carefullyremovetheentireextensionpoletoexposetheshaftand

ballholder.Makesurethettingontheextensionpoledoesnot

move during removal of the extension pole.

4. Placealockingpliersontheshaftascloseaspossibletotheseal

assembly.Whileholdingthesealassemblyinplacewithawrench,

unthreadtheshaftfromthesealassemblyusingthelockingpliers.

5. Removethetriggerguard.

a. Pullthebackofthetriggerguarddownsothatitcomesloose

fromtheswivelassemblyonthehandle.

b. Twistthefrontofthetriggerguardoutoftheslotinthegun

head.

Loading...

Loading...