©TitanToolInc.Allrightsreserved. 3

6. Removethetwotriggerscrewsthatsecurethetriggertothegun

head.Removethetrigger.

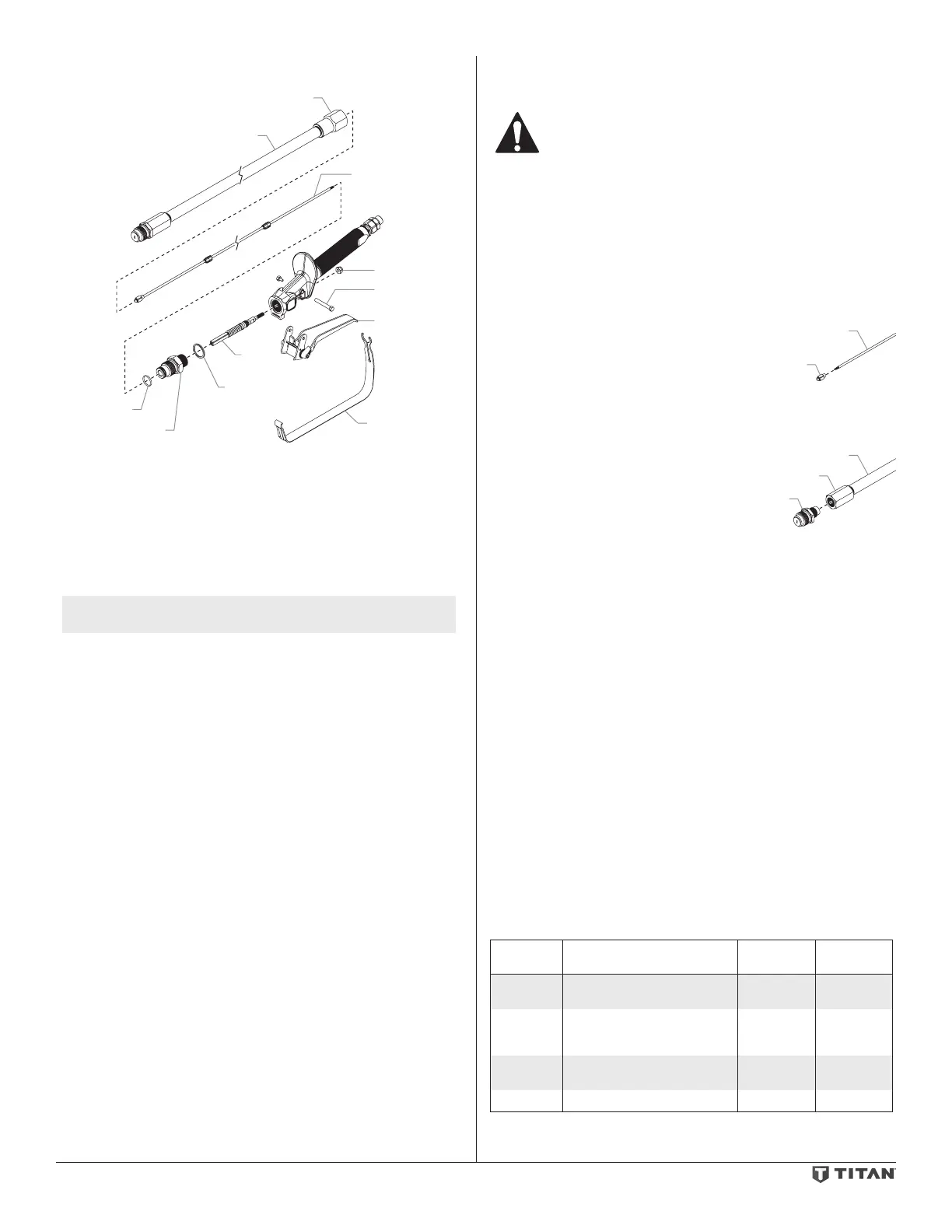

Shaft

Lock Nut

Trigger Scre

Trigger

Trigger Guard

Seal

Assembly

Seal

Washer

Extension Pole

O-Ring

ittiing

7. Placethegunheadinaviseandremovethegunheadtting.

8. Usinga3/8”socket,removethelocknutfromthethreadedendofthe

sealassemblyinsidethebackofthegunhead.

9. Usingapliers,pullthesealassemblyfromthefrontofthegunhead.

Becarefulnottodamagethethreadsinsidethegunhead.

10. Removethesealwasherfromthegunhead.

11. Soaktheremovedpartsintheappropriatesolventandwipeclean.

12. Inspectthepartsforwearordamageandusenewpartsduring

reassemblyofthegun,whennecessary.

NOTE: Lubricate all packings and moving parts with a lithium-

based grease before reassembly.

13. Installthenewsealassemblyintothefrontofthegunhead.Make

surethethreadedportionofthesealassemblyisalignedwiththe

rectangularholeinthebackofthegunhead.

14. Threadthelocknutontothethreadedshaftofthesealassemblyin

thebackofthegunhead.Tightenthenutuntilapproximately1/16”

ofthesealassemblyshaftsticksoutpastthenut.

15. Applyalithium-basedgreasetobothsidesofthenewsealwasherand

insert the washer into the groove inside the gun head.

16. Installthegunheadttingintothegunheadandtightenuntilthehex

onthettingmeetsthegunhead.Makesurethesealwasherremains

in the groove inside the gun head during installation. Torque to

45–50ft./lbs.

17. Reassemblethetrigger.

18. Inspecttheo-ringonthegunheadttingandreplaceifnecessary.

19. ApplyLoctitetothethreadsontheshaft.Holdthesealassemblyin

placewithawrenchandthreadtheshaftintothesealassemblyuntil

itstopsonthechamferedshoulder.Donotapplyexcessiveforceon

the shaft.

20. Lubricatetheo-ringonthegunheadttingandreassemblethe

extensionpoletothegunheadtting.Triggerthegunbeforenal

tighteningoftheextensionpoletopreventdamagetotheballholder.

21. Testtheoperationofthetrigger.Thereshouldbeasmallamountof

play in the trigger after the trigger is released. This will ensure that

theballholderisfullyseatedinthediuserandthegunisshuto

when the trigger is released. Adjust the position of the lock nut on the

sealassemblyiftriggeradjustmentisnecessary.

22. Reassemblethetriggerguard.

23. Startthesprayerandpressurizethegun(refertotheinstructionsin

thesprayer’sOwner’sManual).Checkthegunforleaks.

24. Movethetriggerlocktothelockedposition.Pullthetriggerand

check for leaks.

Replacing the Ball Holder and Diuser

Usethefollowingproceduretoreplacetheballholderanddiuseronthe

spray gun.

Never attempt to perform maintenance on the spray gun

without first performing the “Pressure Relief Procedure.”

1. Disconnecttheairlesssprayhosefromthegun.

2. Removethetipguard,tipswivel,andpolemountfromthegun.

3. Placeonewrenchonthegunheadttingandanotherwrenchonthe

rear tting of the extension pole. Turn the entire extension pole to

unthread it from the gun head tting.

IMPORTANT: Do not try to remove either of the fittings on the extension

pole. Movement of these fittings will break the factory seal and cause the

gun to leak.

4. Carefullyremovetheentireextensionpoletoexposetheshaftand

ballholder.Makesuretothesupporttheshaftduringremovalofthe

extension pole.

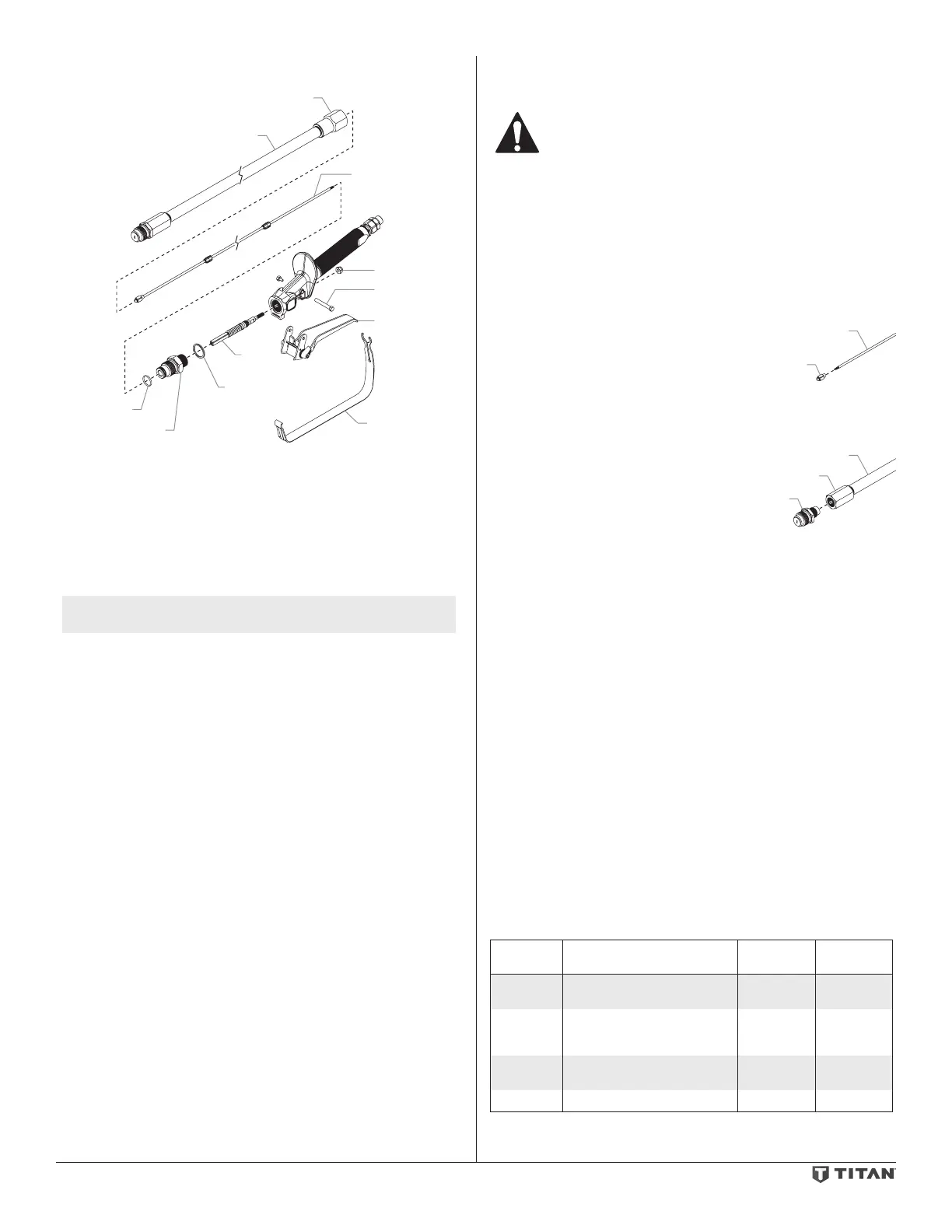

Shaft

Ball

Holder

5. Placealockingpliersontheshaftas

closeaspossibletotheballholder.

Whileholdingtheshaftinplacewith

thelockingpliers,unthreadtheball

holder from the shaft using a wrench.

6. ApplyLoctitetothethreadsofthe

shaftandthreadthenewballholderontotheshaftuntilitstopsat

theangledshoulderoftheshaft.Donotapplyexcessiveforceonthe

shaftorballholder.

Extension Pole

Diuser

Front Fitting

7. Placeonewrenchonthewrenchats

ofthediuserandanotherwrench

on the front tting of the extension

pole.Unthreadthediuserfromthe

extensionpole.Makesurethetting

on the extension pole does not move

duringremovalofthediuser.

8. Threadthenewdiuserintothefront

ttingoftheextensionpole.Makesuretoholdthettingonthe

extensionpolewithawrench.Torquethediuserto40-50ft./lbs.

9. Inspecttheo-ringonthegunheadttingandreplaceifnecessary.

10. Lubricatetheo-ringonthegunheadttingandreassemblethe

extensionpoletothegunheadtting.Triggerthegunbeforenal

tighteningoftheextensionpoletopreventdamagetotheballholder.

11. Testtheoperationofthetrigger.Thereshouldbeasmallamountof

play in the trigger after the trigger is released. This will ensure that

theballholderisfullyseatedinthediuserandthegunisshuto

when the trigger is released. Adjust the position of the lock nut on the

sealassemblyiftriggeradjustmentisnecessary.

12. Startthesprayerandpressurizethegun(refertotheinstructionsin

thesprayer’sOwner’sManual).Checkthegunforleaks.

13. Movethetriggerlocktothelockedposition.Pullthetriggerand

check for leaks.

Replacing/Removing the Filter

1. Pullthebackofthetriggerguarddownsothatitcomesloosefrom

theswivelassemblyonthehandle.

2. Removethehandleassemblyfromthegunhead.

3. Pulltheoldlteroutofthegunhead.

4. Pushtheneworcleanedlterintothegunhead.

5. Makesurethehandlesealisinpositionandthreadthehandle

assemblyintothegunheaduntilsecure.

6. Snapthetriggerguardbackontothehandleassembly.

Filter Chart

Part

Number

Application Filter Type Color of

Filter Body

550-486 Syntheticresin,enamels,clean

varnishes,stains,azures

Extrane red

550-485 Basecoatenamels,primer

enamels,llers,markingpaints,

textured enamels

Fine yellow

550-483 Emulsions,latexpaints,acrylic

paints

Medium white

550-484 Fillerpaints,largeareasurfaces Coarse green

Loading...

Loading...