TROUBLESHOOTING

All troubleshooting should only be performed by a qualified carbon dioxide service

technician. Reference the appropriate Wiring Schematic Drawing and the appropri-

ate Process and Instrumentation Diagram Drawing in the Appendix of this manual

for component identification.

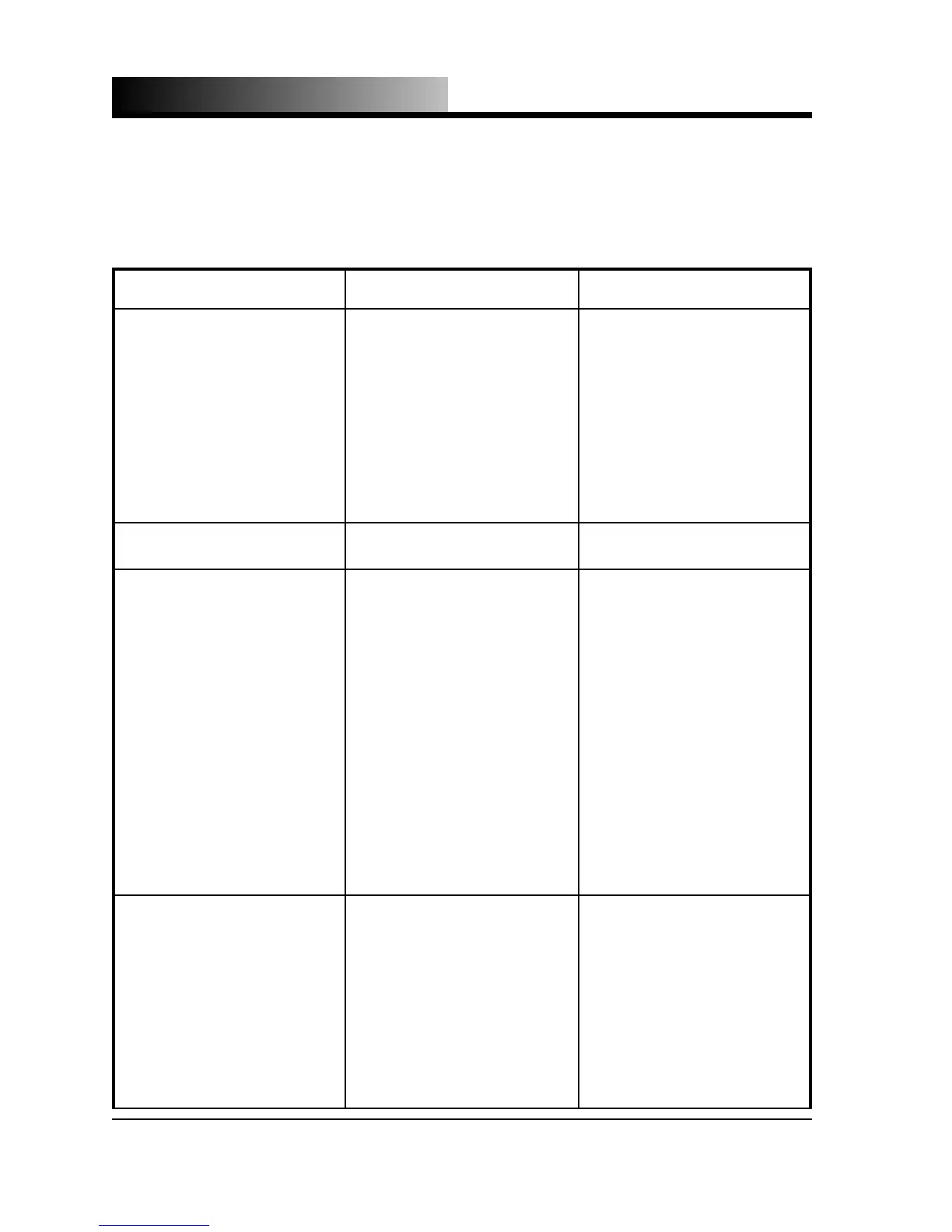

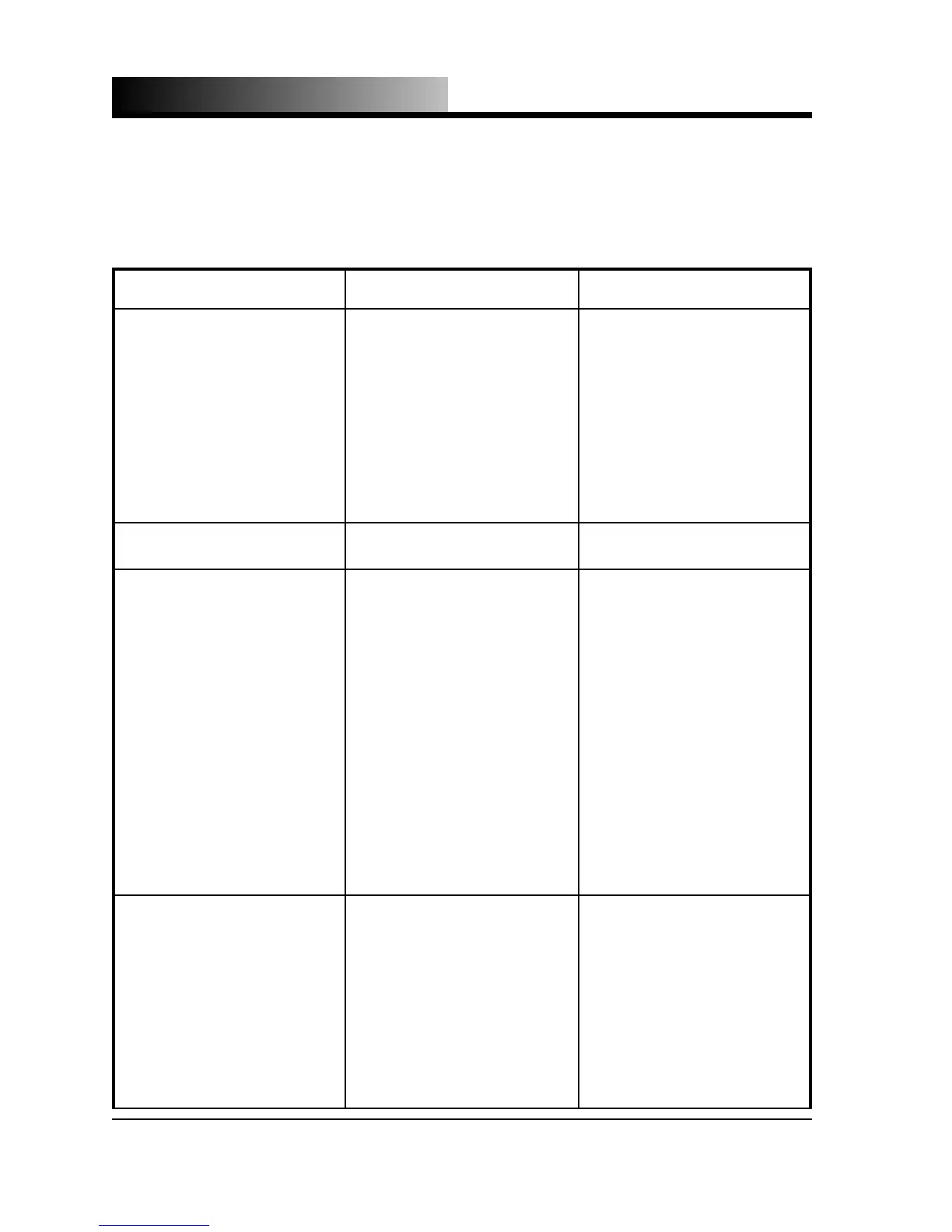

PROBLEM POSSIBLE CAUSE REMEDY

Compression cylinder pressure too high

(55 - 60 psig (3.79 - 4.13 bar))

1. Moisture or debris on the exhaust fil-

ter screen

2. Restriction in the vapor exhaust line

3. Metering valve open too much

4. Injection valve not closing properly

1. Replace or clean according to the

procedure on page 4.6

2. Locate and remove restriction

3. Close valve until pressure drops to

35 - 40 psig (2.4 - 2.8 bar) during liq-

uid CO

2

injection

4. Check vapor supply pressure, should

be minimum 90 psig (6.2 bar) - if

vapor supply pressure above 90 psig

(6.2 bar), repair or replace injection

valve actuator

Compression cylinder pressure too high

(exceeds 60 psig (4.13 bar))

1. Over pressure switch out of adjust-

ment or defective

2. Repair or replace and troubleshoot

causes 1-4 above

Compression cylinder pressure too low

(0 - 20 psig (0 - 1.37 bar))

1. Closed or restricted liquid supply line

2. Metering valve closed too much

3. Storage unit pressure too low

4. Injection valve not opening fully

5. Transition box leaking

6. Injection valve not seating properly,

allowing CO

2

to leak through when

closed causing plug

1. Check supply valve and/or strainer or

filter

2. Open valve during injection cycle until

pressure rises to 35 - 40 psig (2.4 -

2.8 bar)

3. Storage unit pressure should be

minimum 200 psig (13.8 bar), 250 -

300 psig (17.2 - 20.7 bar) is

preferable

4. Check the vapor supply pressure

(max 125 psig (8.6 bar))

5. Replace gasket(s), check and replace

filter screen according to procedure

on page 4.6 if necessary

6. Repair or replace

Dry ice pellets blow out during compres-

sion stroke

1. Dirt, moisture or debris on the

exhaust filter screen causing ex-

cessive pressure

2. Excess vapor trapping between pis-

ton face and plug on compression

stroke

3. Limit switch out of adjustment caus-

ing dry ice plugs that are too short

1. Replace or clean according to the

procedure on page 4.6

2. Adjust timer(s) T1 and/or T2 in con-

trol panel to higher setting to increase

the delay prior to the compression

stroke, allowing the excess vapor

time to exhaust

3. Adjust limit switch away from extru-

sion die slightly to produce longer dry

ice plugs

5.1

Loading...

Loading...