REPAIR & ADJUSTMENTS

All repairs and adjustments should be performed by a qualified carbon dioxide equip-

ment service technician. The following applies to all single pump machines.

HIGH-LOW PRESSURE COMPENSATOR ADJUSTMENT

The high-low pressure compensator will provide the highest possible pump flow until a

preset pressure is reached. The pump then de-strokes to provide a minimum preset flow

rate regardless of system pressure. The high-low pressure compensator is preset at the

factory but may need to be adjusted, particularly after pump repair or replacement. The

high-low pressure compensator must be adjusted properly to provide satisfactory pump

operation.

1. Disconnect electrical power and follow your company’s lock out and tag out safety

procedures.

2. Using a 9/16” wrench, loosen the high-low pressure compensator adjustment bolt

locknut by turning it counterclockwise.

3. Turn the high-low pressure compensator adjustment bolt counterclockwise by hand

until it is completely removed.

4. Reinstall the high-low pressure com-

pensator adjustment bolt, very gently

turning it by hand until it makes con-

tact with the internal compensation

spool.

5. Turn the adjustment bolt 1/4 turn

clockwise, slightly compressing the

compensation spool.

6. Hold the adjustment screw to prevent

it from turning and tighten the lock-

nut.

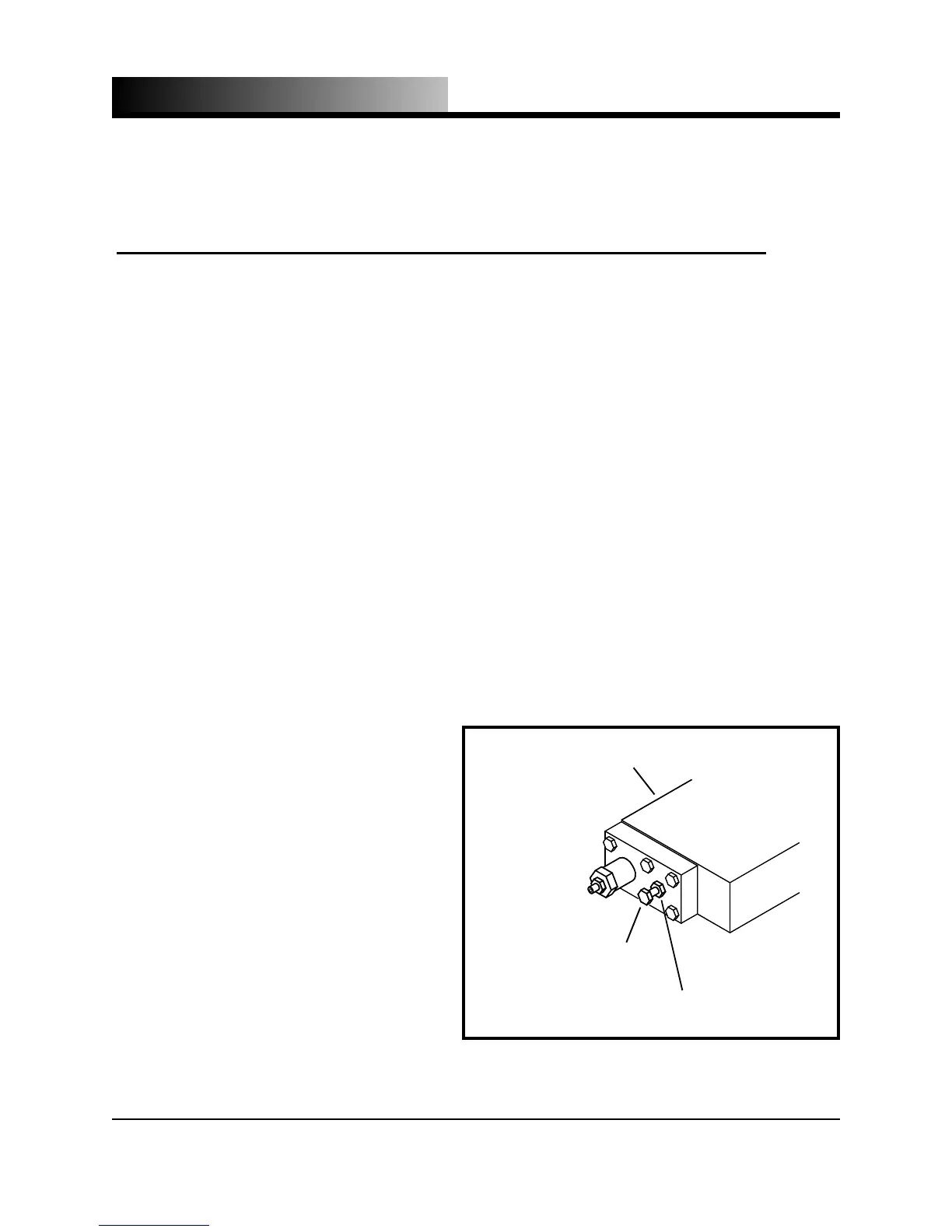

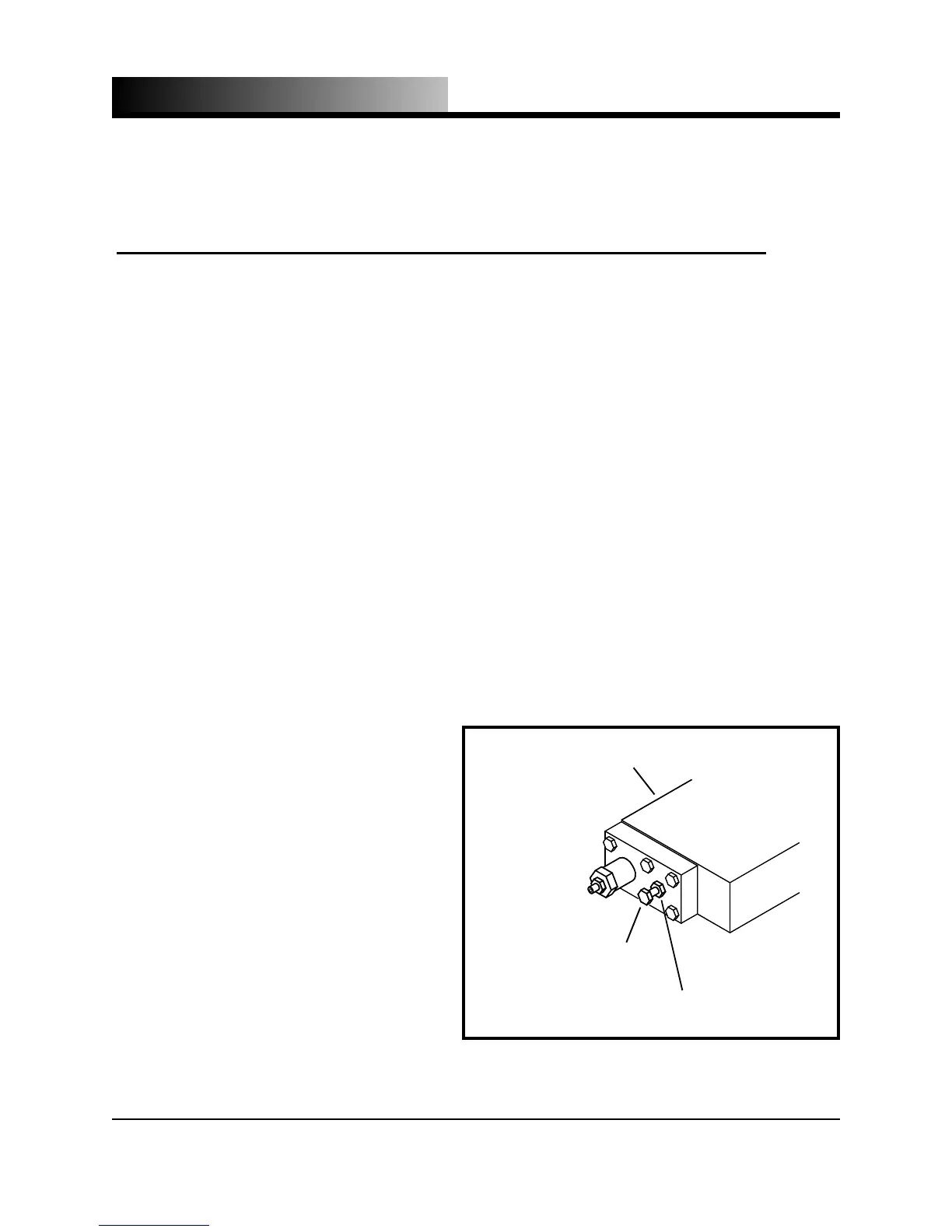

6.1

HYDRAULIC PUMP

CONTROL BODY

PRESSURE COMPENSATOR

ADJUSTMENT BOLT

PRESSURE COMPENSATOR

ADJUSTMENT BOLT LOCKNUT

Figure 6.1 - High-Low Pressure

Compensator Adjustment

Loading...

Loading...