Page 4

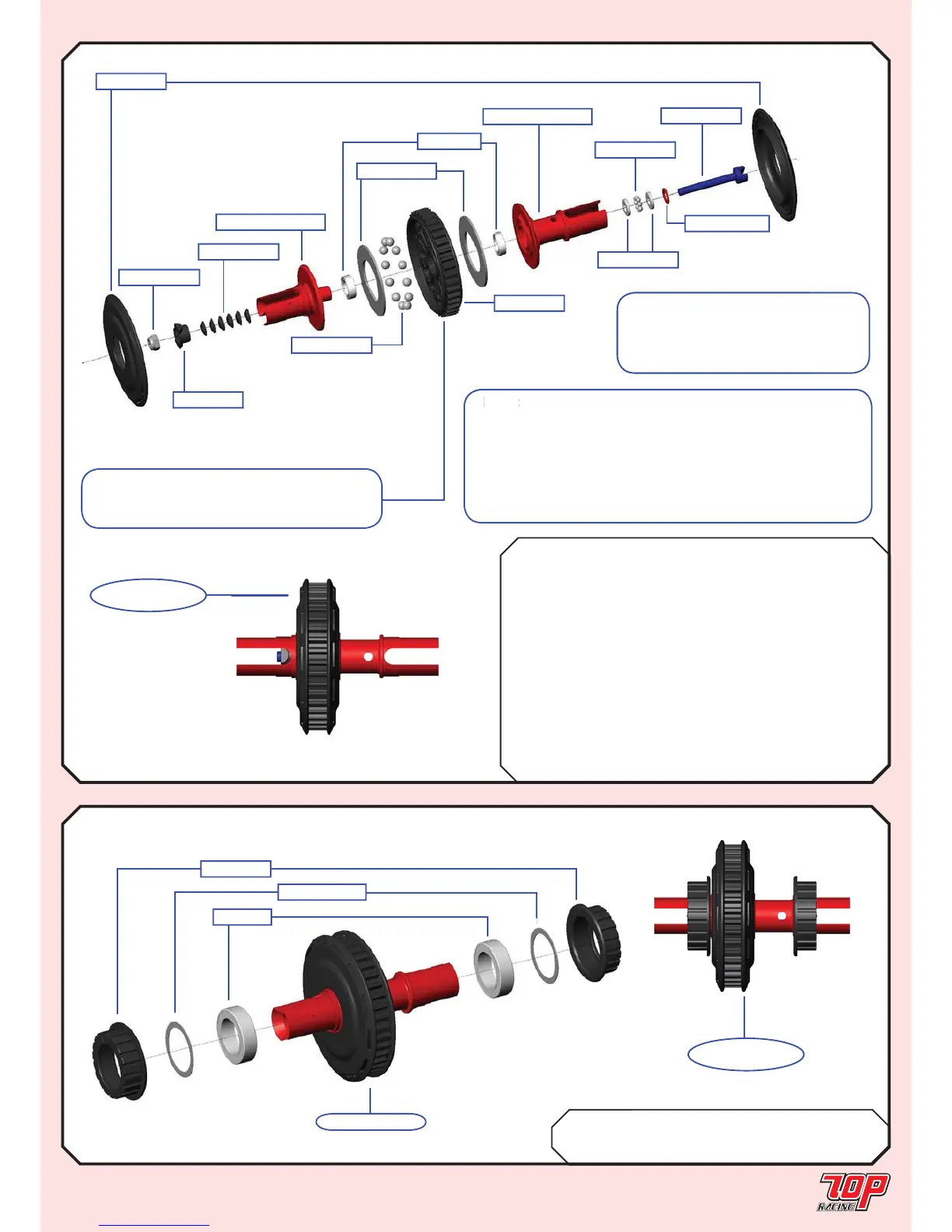

DIFFERENTIAL (Rubber Asphalt Edition - Make 1; Foam Carpet Edition - Make 2)

BAG B Mold L-04-1 40T Diff Pulley x 1

Mold L-05-1 40T Flange/Dust Cover x 2

Mold L-06-1 Differential Nut Retainer x 1

PA-DR0001-1 Diff. Ring x 2

PA-LN0M26-1 M2.6 Locknut x 1

PA-SDB301-1 3mm Diff. Balls x 12

PA-SDB401-1 Thrust Balls x 8

TC-PDT001-1 M2.6 Diff. Screw x 1

TC-PDT002RD-A-1 Alloy Diff. Outdrive - A x 1

TC-PDT002RD-B-1 Alloy Diff. Outdrive - B x 1

TC-PDT003-1 2.6mm Thrust Washer x 2

TC-PDT004-1 Diff. Cone Washers x 6

AW-S050RD-1 3 x 5.5 x 0.5mm Collar x 1

MR85ZZ-1 5 x 8 x 2.5mm Bearing x 2

STEP 04

STEP 05

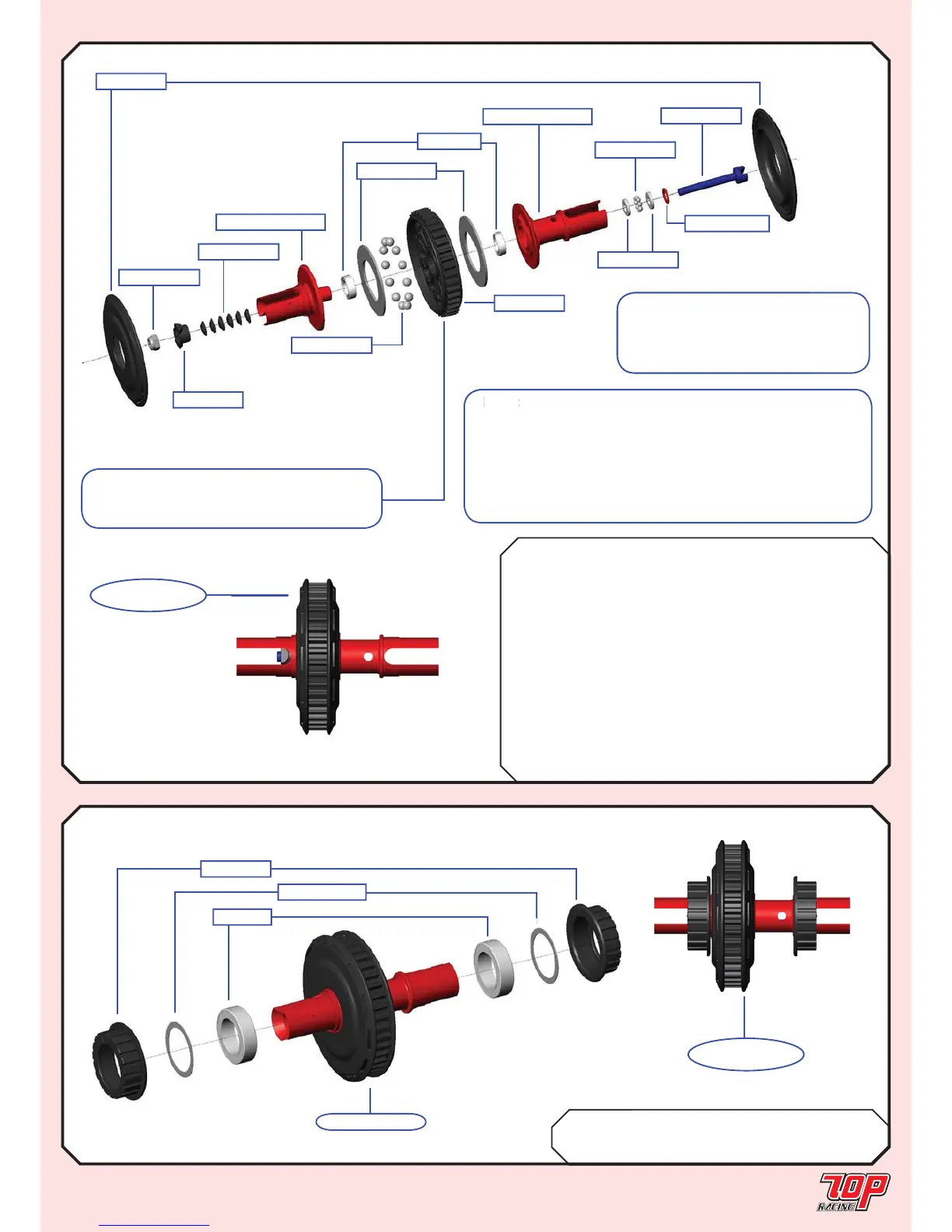

BAG B PA-101215-C-1 12 x 0.3mm Shim x 2

Mold L-01-1 Bearing Cam x 2

6700ZZ-1 10 x 15 x 4mm Bearing x 2

Note: Apply small amount of black

grease (not included) in between the

2.6mm thrust washers and at the

thrust balls.

Note: The tightness of the diff. is controlled by the diff.

screw. It should be adjusted according to driving style and

track condition. To avoid the end of the diff. screw from

touching the dog bone C drive in STEP 15 when using smaller

rear toe-in or larger camber angles, reduce the number of diff.

cone washers to 4 pcs or use our optional 44.5mm universal

bone (SOLD SEPARATELY).

STEP 04

FINISHED

PA-101215-C-1

6700ZZ-1

from STEP 04

Mold L-01-1

STEP 05

FINISHED

Note

Loading...

Loading...