Page 5

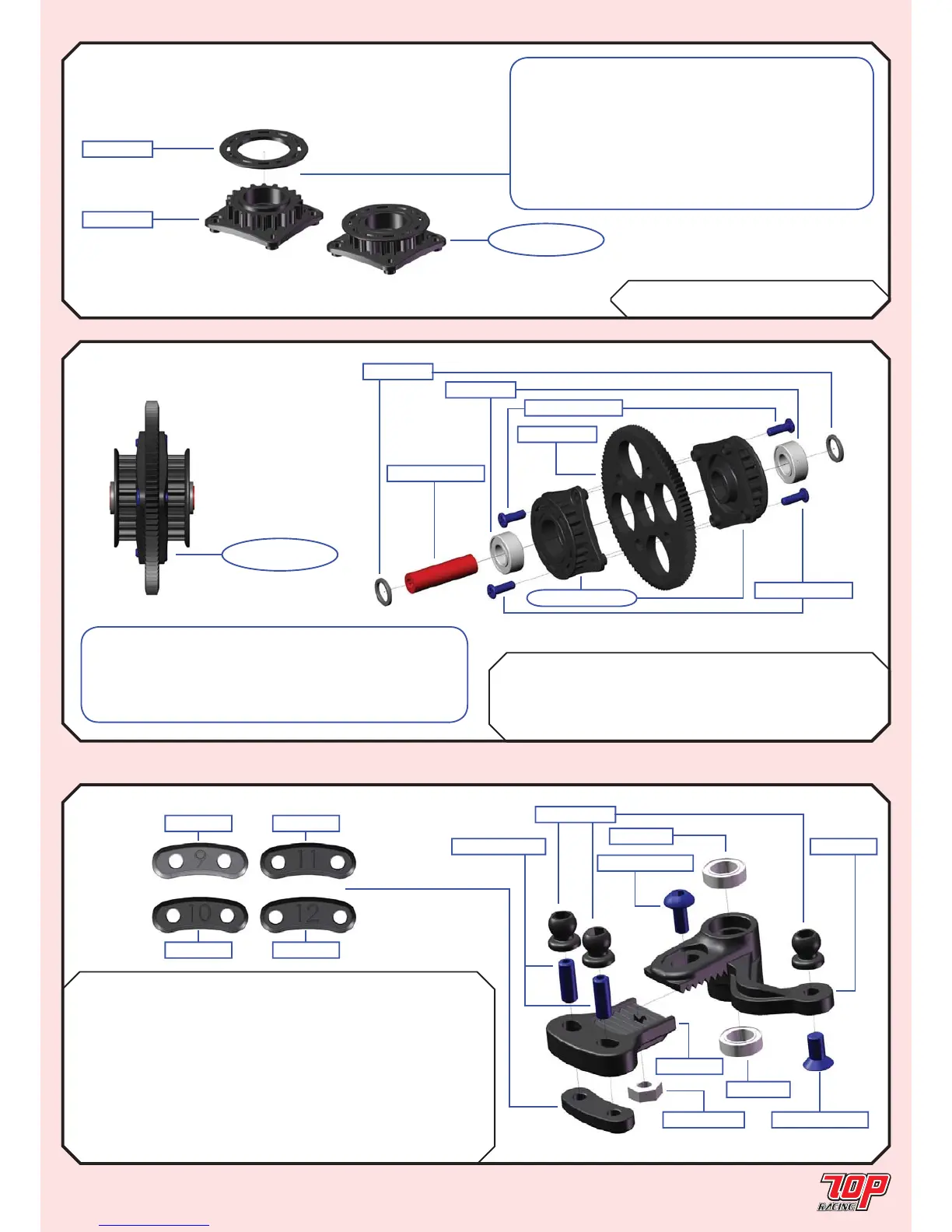

CENTER DRIVE

STEP 06

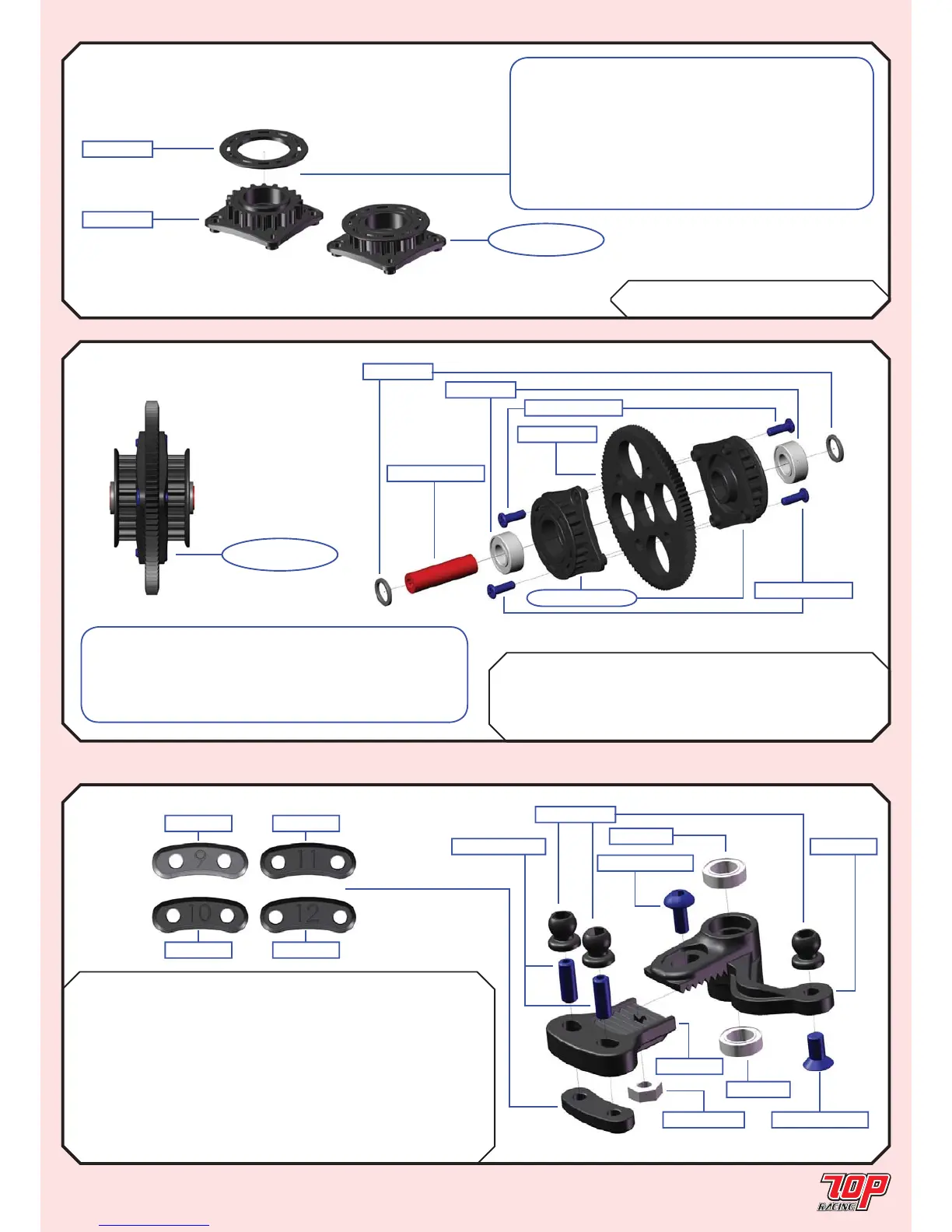

STEP 08

Rubber Foam

BAG C Mold I-01-1 Bell Crank x 1 x 1

Mold I-02-1 Bell Crank Extension x 1 x 1

Mold I-04-1 BCE Insert #10 x 1

Mold I-05-1 BCE Insert #11 x 1

MR85ZZ-1 5 x 8 x 2.5mm Bearing x 2 x 2

PA-BM0306BK-1 M3x6mm Button Head Screw x 1 x 1

PA-FN00M3-1 M3 Nut x 1 x 1

PA-HBS003-1 5.3mm Ball (Steel) x 3 x 3

PA-SS0308BK-1 M3x8mm Set Screw x 2 x 2

PA-CM0306BK-1 M3x6mm Countersunk Screw x 1 x 1

BAG C Mold L-07-1 Center Shaft Spacer x 2

MR105ZZ-1 5 x 10 x 4mm Bearing x 2

SG-K64100-1 100T 64P Spur Gear x 1

TC-PDT005RD-1 Centre Pulley Shaft x 1

PA-SCM205BK-1 M2x5mm Chess Head Screws x 4

STEP 07

BAG C Mold L-02-1 20T Pulley x 2

Mold L-03-1 20T Flange x 2

STEERING CRANK

STEP 07

FINISHED

Mold L-07-1

MR105ZZ-1

SG-K64100-1

PA-SCM205BK-1

TC-PDT005RD-1

from STEP 06

PA-SCM205BK-1

Mold L-02-1

Mold L-03-1

STEP 06

FINISHED

Note: Apply a small amount of instant glue in

betwwen the 20T pulley and 20T fl ange. Be careful

not to let the glue go onto the teeth of the pulleys.

The fi tting between Mold L-03-1 and Mold L-02-1 are

purposefully designed to have a tight fi tting. Be very

carefull when applying instant glue at the contact edge

AFTER the 2 parts are locked together.

Make a total of 2 sets for this step.

Mold I-03-1

Mold I-06-1

Mold I-04-1

Mold I-05-1

PA-HBS003-1

PA-SS0308BK-1

PA-BM0306BK-1

MR85ZZ-1

MR85ZZ-1

Mold I-02-1

Mold I-01-1

PA-FN00M3-1 PA-CM0306BK-1

Note: Slightly ream out both sides of the four 3mm

holes on the spur gear where the 20T pulleys go into,

because plastic burr may exist at these locations. Use

ONLY T.O.P. and Xenon spur gears. These are the ones

that fi t best with our 20T pulleys.

Loading...

Loading...