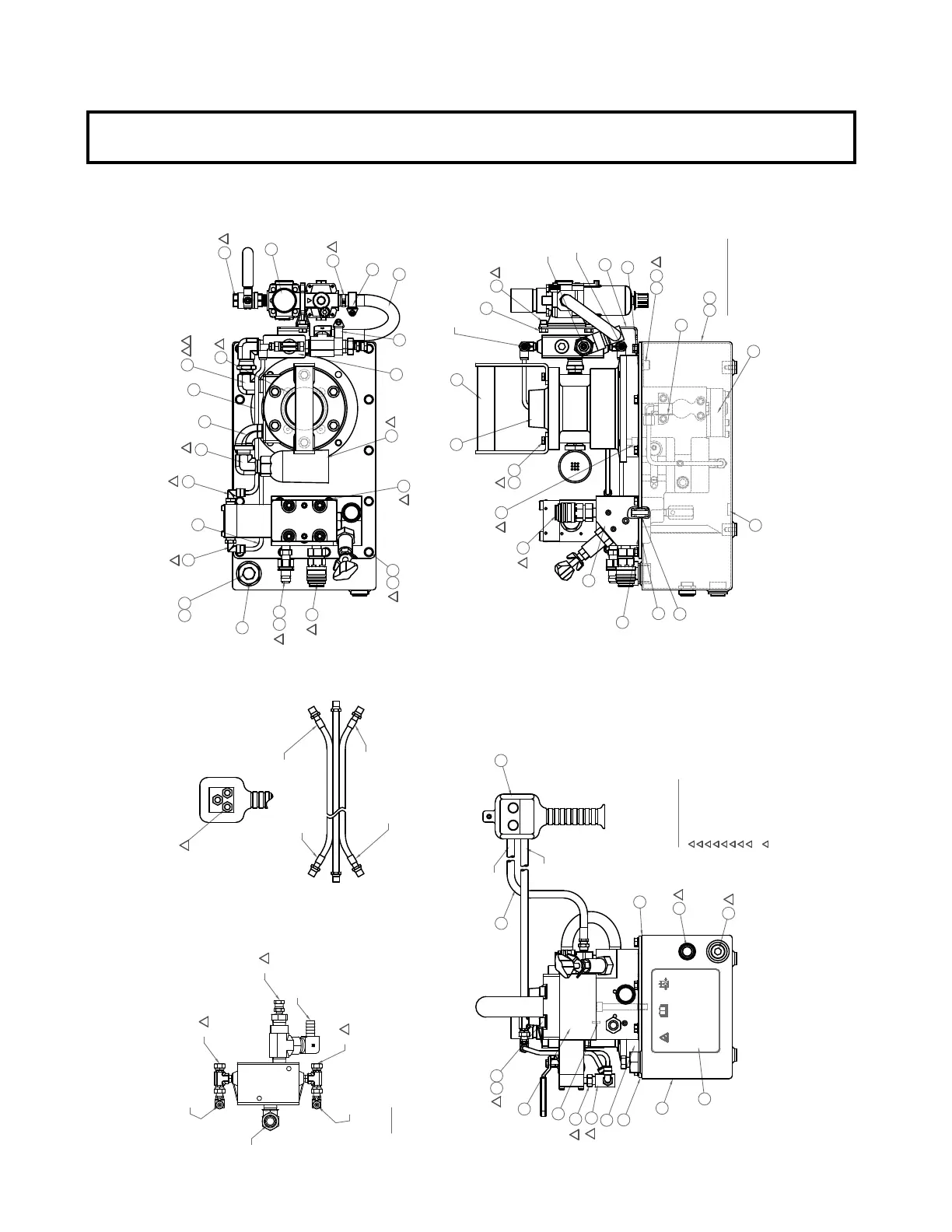

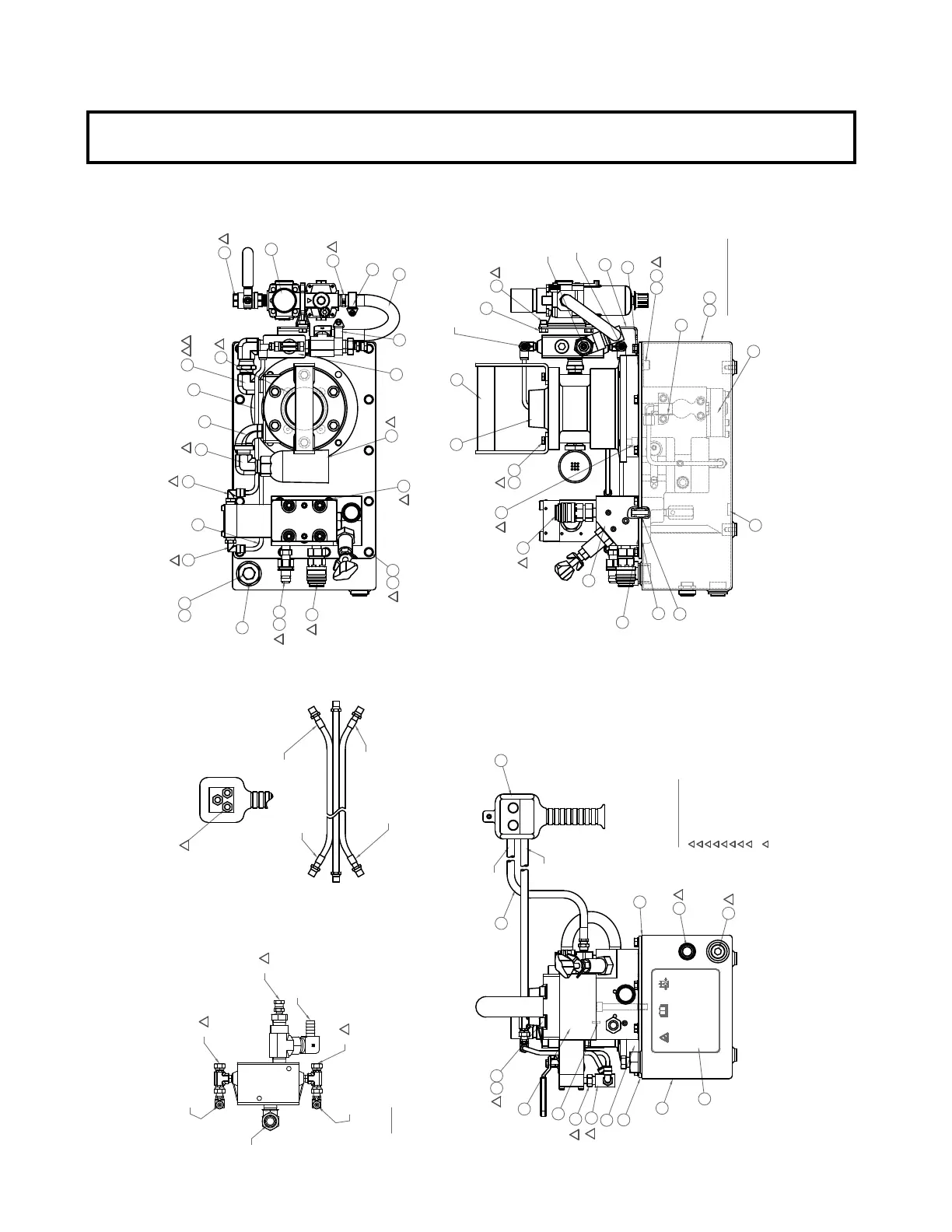

COMMON COMPONENTS

Note: This illustration is for reference only. The appearance of your unit may differ from unit shown.

4

90

3

45

6362

59

94

81

81

72

24

2

21

70

75

74

76

13

75

2120

19

15

83

84

88

98

78

91

87

97

96

82

86

9595

BLACK

YELLOW

A

@ PENDANT

B A

P

P

B

A

YELLOW

BLACK

P

B

73

79

22

5857

STOP RUN

41

59

88

98

89

92

15"

92

15"

TORC-UP MODEL #:

AP1000

NOTES:

TEST PUMP FOR FLOW @ 0, 5,000, 10,000 PSI.

RECORD FLOW, RPM, AND AIR PRESSURE.

SET CROSSOVER @ 1,200-1,300 PSI.

SET INTERNAL RELIEF @ 10,200-10,500 PSI.

SET RETRACT RELIEF @ 1,700-1,800 PSI.

SHIP PACKAGED OIL WITH PUMP.

11

BEFORE OPERATING PUMP:

1. Check instruction manual for required air supply.

2. Use dry lubricated air. 100 PSIG maximum. Antifreeze lubricant should be used in oiler and muffler

to prevent freeze-up.

3. Use only equipment rated for 10,000 PSI / 700 BAR.

4. Make sure all connections are tight, secure and kink-free.

5. Check the reservoir oil level. Fill to one inch of the top, if necessary.

6. Never operate the pump without tool movement for more than 1 minute without shifting the control

valve to neutral. Leaving the tool in the advance or retract position without tool movement may

overheat the oil. Do not exceed oil operating temperatures of 140° F or 60° C.

AFTER COMPLETING THE JOB:

1. Before disconnecting your equipment, first be sure the tool is unloaded, then unplug the power cord

and shift the hydraulic controls several times to release system pressure.

2. Store the pump in a clean, dry place.

PERIODIC MAINTENANCE:

1. Change the hydraulic oil and clean the oil screen, breather and magnet (located in the reservoir) twice a

year. Refer to the operating instructions for details. When used in extremely dusty areas or oil has been

overheated, change the oil more frequently.

68394

AIR PUMP INSTRUCTIONS FOR SAFE OPERATION

REVIEW ALL OPERATING

INSTRUCTIONS

SKIN PUNCTURE/

HYDRAULIC LINE

10,000 PSI/

700 BAR

52

6

APPLY LOCTITE 243

12 27

71

16

14

7

5

INSTALL SHIPPING PLUG

87145 AND SHIP BREATHER

VENT 46348 IN A BAG FOR

CUSTOMER TO INSTALL

17

P

A

B

A

B

P

SHUTTLE

VALVE

SHUTTLE VALVE

OTOR

FILTER/LUBRICATOR

P

B

ASSEMBLY NOTES:

TORQUE TO 225-275 IN*LBS

TORQUE TO 45-55 IN*LBS

TORQUE TO 18-22 IN*LBS

TORQUE TO 68-82 IN*LBS

APPLY TEFLON TAPE & TORQUE TO 32-39 FT*LBS

APPLY TEFLON TAPE & TORQUE TO 80-100 IN*LBS

APPLY TEFLON TAPE & TORQUE TO 20-25 FT*LBS

ADD 5-10 DROPS OF PNEMATIC OIL IN FITTING #81

BEFORE INSTALLING INTO MOTOR

APPLY LOCTITE 243 & TORQUE TO 60-72 IN*LBS

AIR CONTROL VALVE #82

PART #DS2284900

PENDANT AND HOSE #'S 41 & 89

PART #'S 68799 & 41965

1

1

1

1

1

2

3

4

4

2

2

2

2

5

5

6

6

6

6

3

4

1

2

7

5

6

7

7

7

7

7

5

8

8

9

9

Loading...

Loading...