8

1. Remove the VOLTA Series Torque Wrench from the application.

2. Disconnect the battery to the VOLTA Series Torque Wrench.

3. Remove and change the socket or accessory adaptor for the next project. Ensure the socket

or accessory is properly secured to the square drive with a locking pin and safety securing

o-ring.

CHANGING ACCESSORIES

TIGHTENING AND LOOSENING OF BOLTS OR NUTS

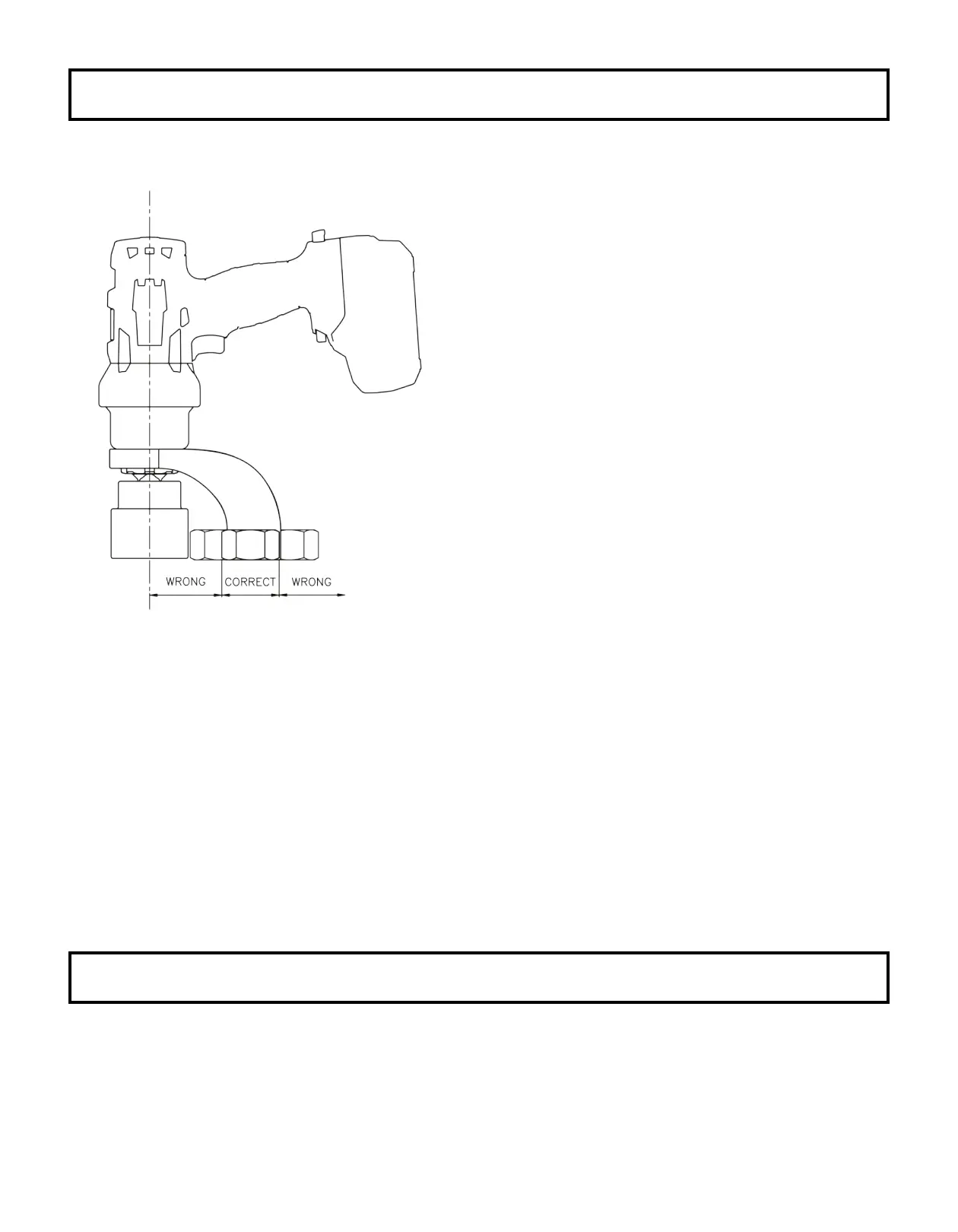

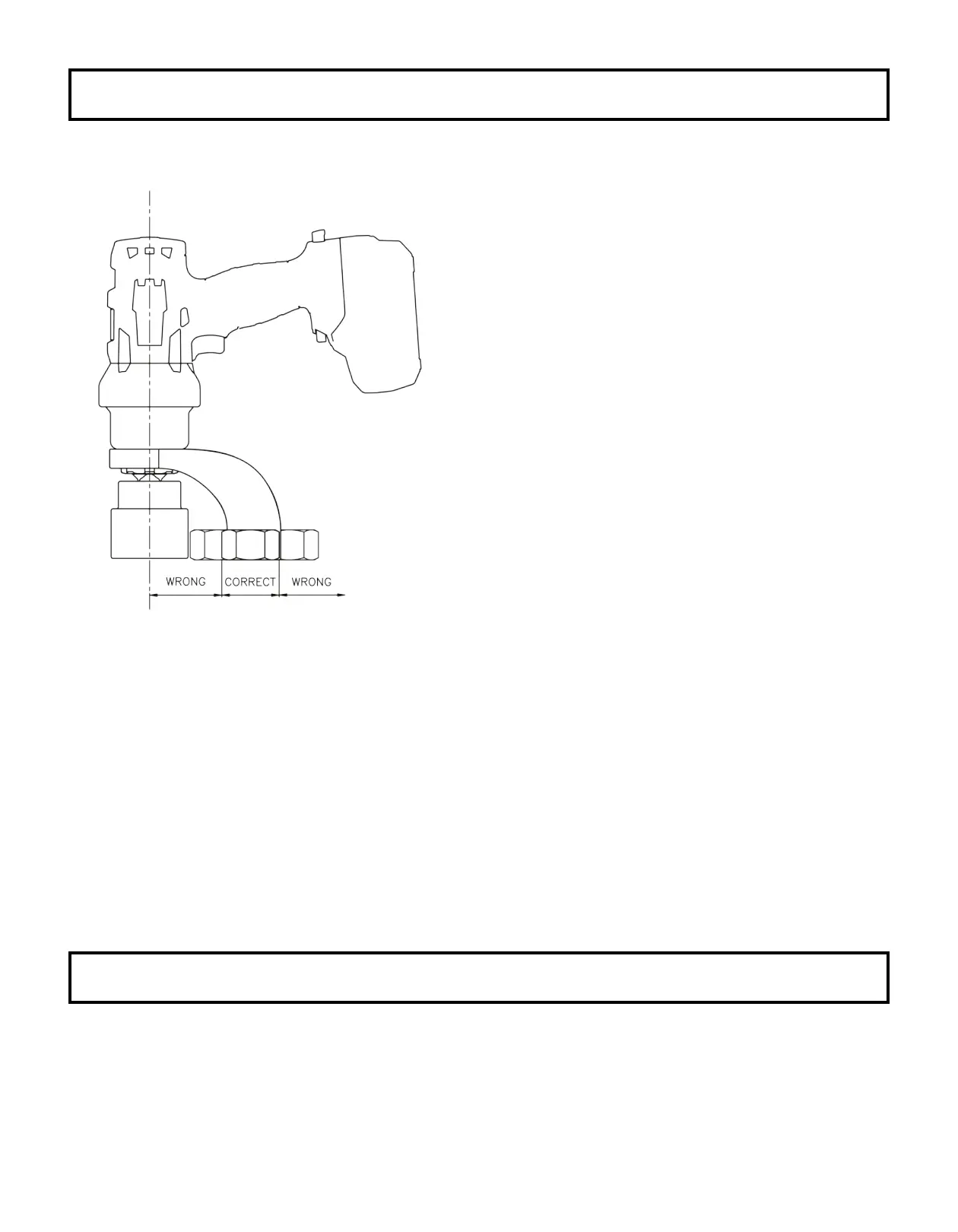

Fig. 1

1. Place your VOLTA Series Torque Wrench

completely over and on the fastener to be

tightened or loosened.

2. Ensure the reaction area / movement is taken

up by the Reaction Arm. Also, ensure the

reaction is stable and will support counter

torque.

3. Hold the VOLTA Series Torque Wrench

perpendicular to the fastener axis for

the complete duration of the rotation process for

tightening or loosening.

4. Ensure the direction switch is set to tighten.

Then, press the trigger on the pistol grip to

tighten the fastener. The tool will rotate

until the fastener becomes torqued, and the

VOLTA Series Torque Wrench will then stop/beep.

5. For loosening a fastener, place the direction

switch in reverse. Then, press the trigger on

the pistol grip to loosen the fastener.

The unit will continue to rotate until the fastener is removed OR once the fastener is loose it

can be removed by hand and you can move on to the next fastener.

6. Continue the process for tightening or loosening for each fastener you require.

7. If torque requirements necessitate the use of torque increments, set the VOLTA Series Torque

Wrench to your rst torque requirement. Tighten fastener as per your required tightening bolt

sequence. Then, reset for the next setting(s).

8. Your personnel can be trained by your TorcUP Representative or Distributor on use of this

product if so desired.

Loading...

Loading...