tothereelandcounterclockwiserotationmovethe

bedknifeedgeawayfromthereel.Donotovertighten

theadjustingscrews.

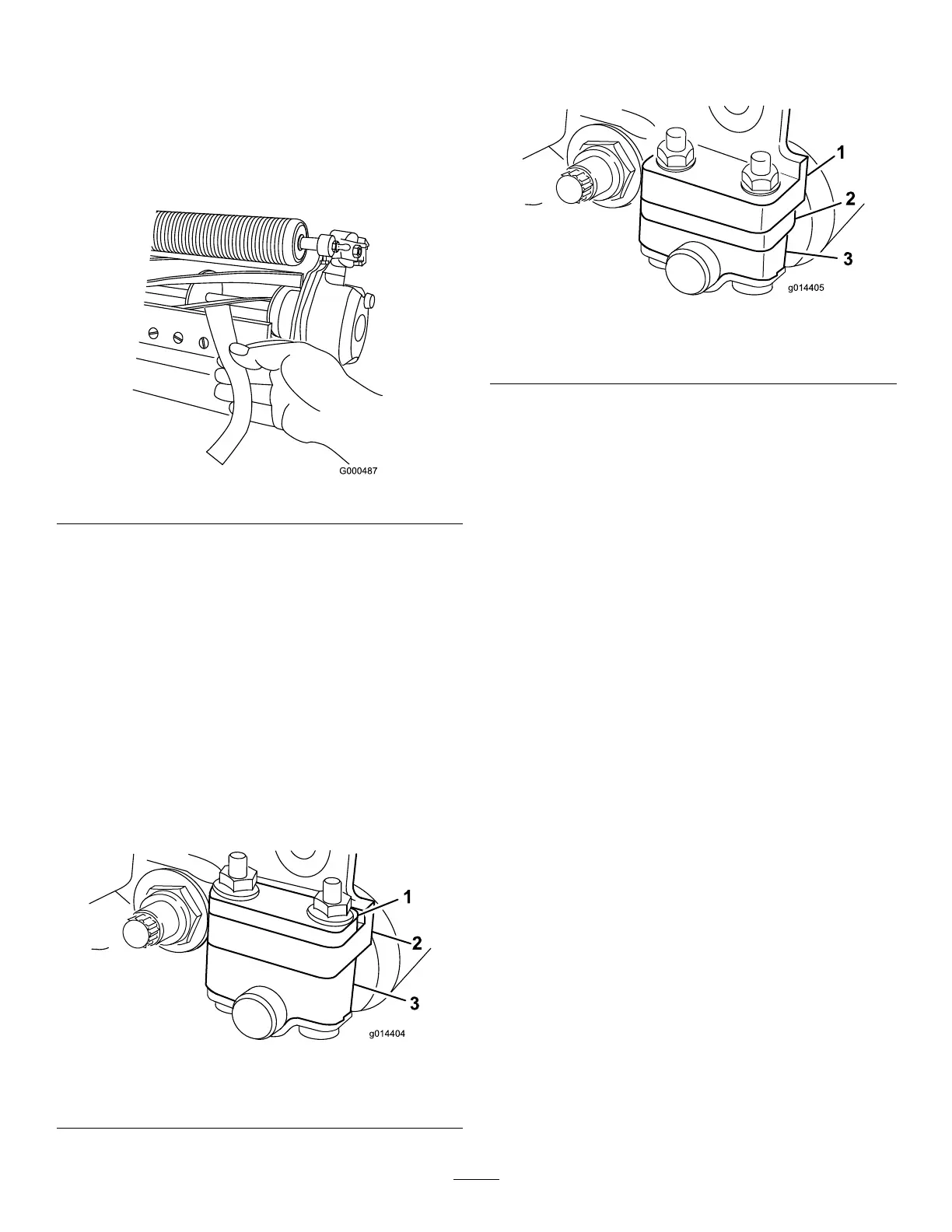

11.Testthecuttingperformancebyinsertingalongstrip

ofcuttingperformancepaper(Toropartnumber

125-5610)betweenthereelandbedknife,perpendicular

tothebedknife(Figure5).Slowlyrotatethereel

forward;itshouldcutpaper

Figure5

Note:Ifexcessivecontact/reeldragisevidentitwill

beeithernecessarytobacklap,refacethefrontofthe

bedknife,orregrindthecuttingunittoachievethe

sharpedgesneededforprecisioncutting(Refertothe

ToroManualforSharpeningReelandRotaryMowers,

FormNo.09168SL).

AdjustingtheRearRoller

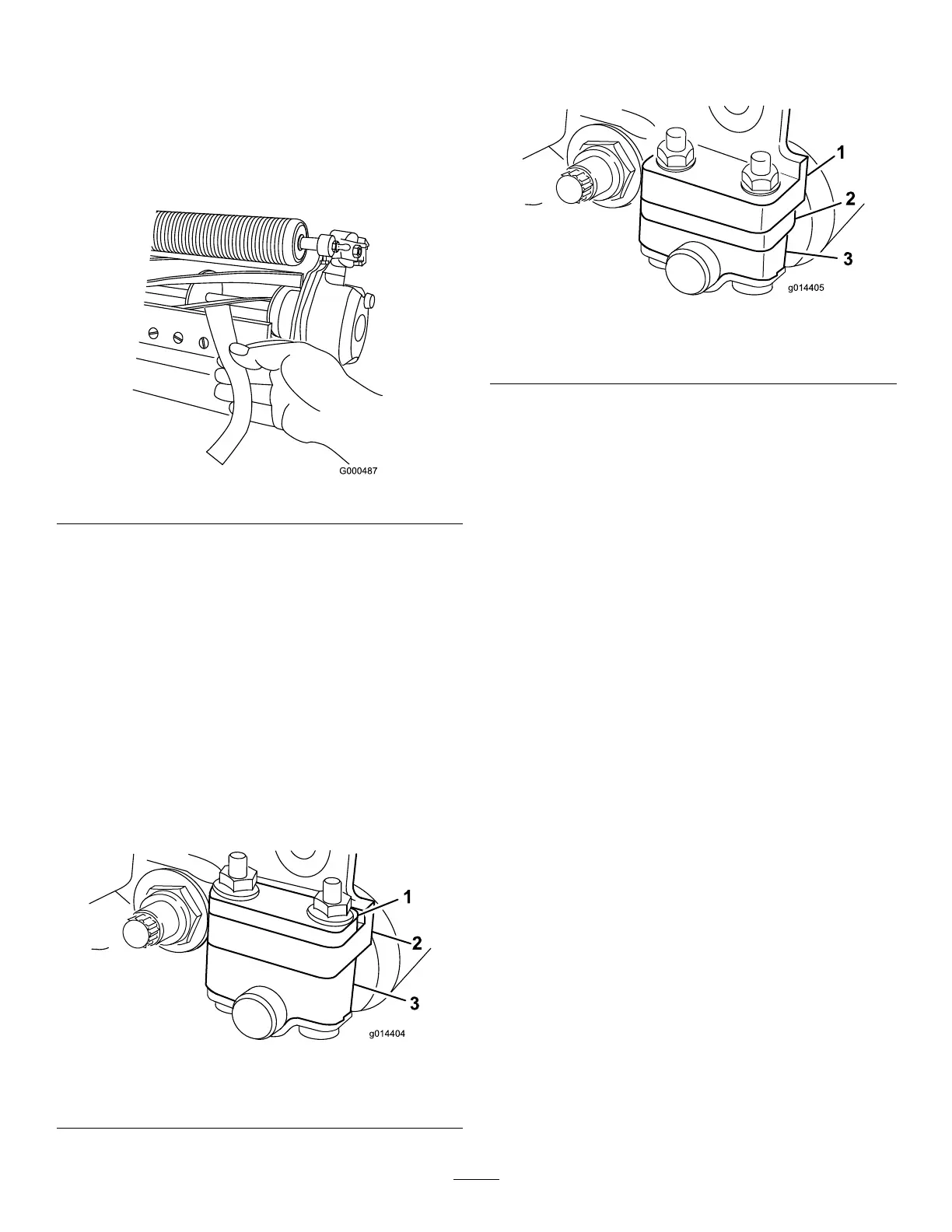

1.Adjusttherearrollerbrackets(Figure6orFigure7)

totheloworhighpositiondependingonthedesired

heightofcutrange.

Positionthespacerabovethesideplatemountingange

(factorysetting)whenheightofcutsettingsrangefrom

1.6to6mm(1/16to1/4inch)(Figure6).

Figure6

1.Spacer3.Sideplatemountingange

2.Rollerbracket

Positionthespacerbelowthesideplatemounting

angewhenheightofcutsettingsrangefrom3to25

mm(1/8to1inch)(Figure7).

Figure7

1.Spacer3.Sideplatemountingange

2.Rollerbracket

2.Toadjustrearrollerproceedasfollows:

A.Raisetherearofthecuttingunitandplaceablock

underthebedknife.

B.Removethe2nutssecuringeachrollerbracket

andspacertoeachsideplatemountingange.

C.Lowertherollerandscrewsfromthesideplate

mountingangesandspacers.

D.Placethespacersontothescrewsontheroller

brackets.

E.Securetherollerbracketandspacerstothe

undersideofthemountingangeswiththenuts

previouslyremoved.

Note:Thepositionoftherearrollertothereel

iscontrolledbythemachiningtolerancesofthe

assembledcomponentsandparallelingisnotrequired.

AdjustingtheHeightofCut

Note:Forheightsofcutgreaterthan1.270cm(0.500inch),

youmustinstallthehighheightofcutkit.

Important:Wheneverthecuttingunithastobetipped

toexposethebedknife/reel,propuptherearofthe

cuttingunittomakesurethenutsonthebackendof

thebedbaradjustingscrewsarenotrestingonthework

surface(Figure3).

1.Loosenthelocknutssecuringtheheight-of-cutarmsto

thecuttingunitsideplates(Figure8).

5

Loading...

Loading...