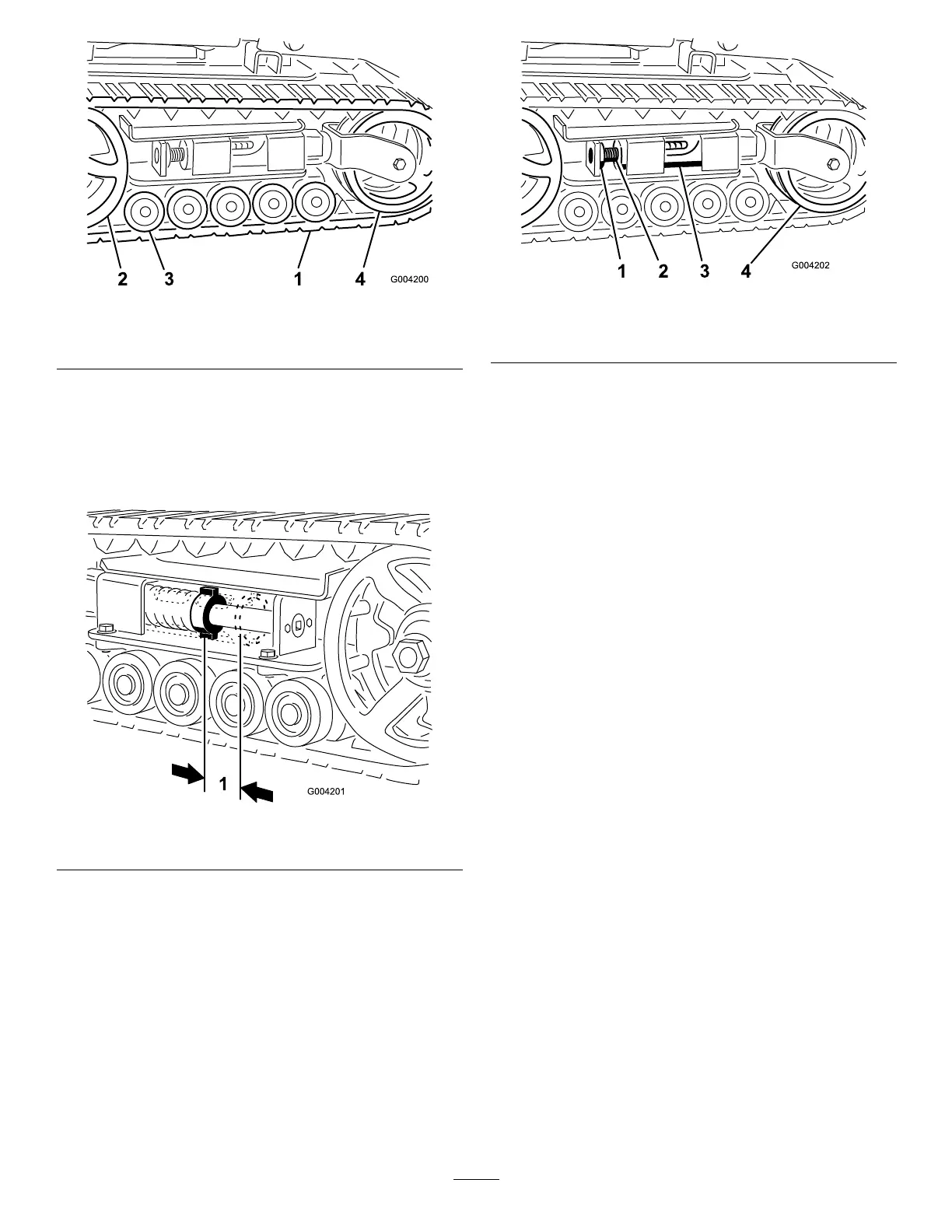

Figure39

1.Track3.Roadwheels

2.Drivesprocket4.Tensionwheel

AdjustingtheTrackTension

Thereshouldbe2-3/4inches(7cm)betweenthetension

nutandthebackofthetensiontube(Figure40).Ifnot,

adjustthetracktensionusingthefollowingprocedure:

Figure40

1.2-3/4inches(7cm)

1.Lowertheloaderarms,stoptheengine,andremove

thekey.

2.Lift/supportthesideoftheunittobeworkedonso

thatthetrackisoffoftheground.

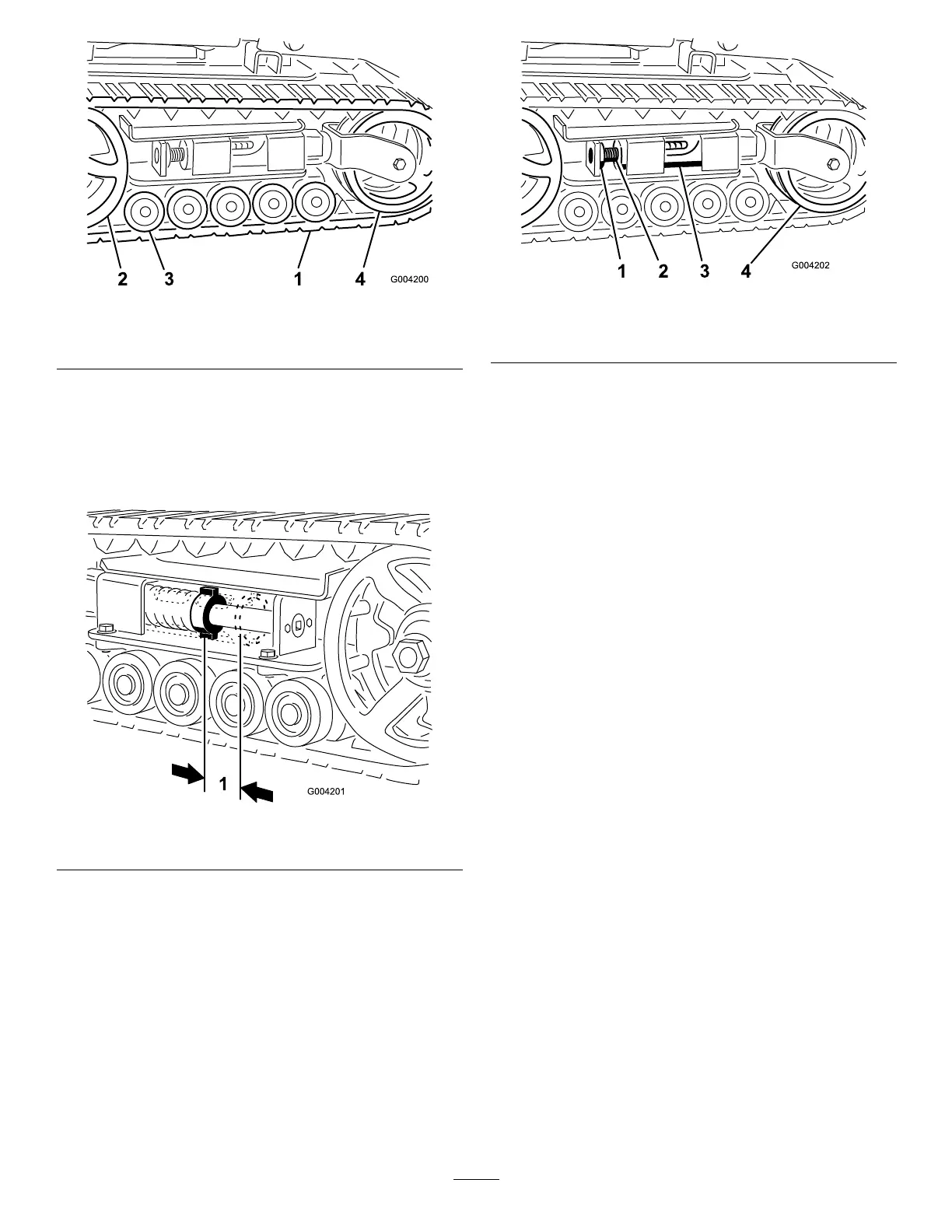

3.Removethelockingboltandnut(Figure41).

Figure41

1.Lockingbolt3.Tensiontube

2.Tensioningscrew4.Tensionwheel

4.Usinga1/2inchdrivesocketwrench(Figure42),

turnthetensioningscrewcounter-clockwiseuntilthe

distancebetweenthetensionnutandthebackofthe

tensiontube(Figure40)is2-3/4inches(7cm).

5.Aligntheclosestnotchinthetensionscrewtothe

lockingboltholeandsecurethescrewwiththe

lockingboltandnut(Figure41).

6.Lowerthetractionunittotheground.

ReplacingtheTracks(Models22321

and22321G)

Whenthetracksarebadlyworn,replacethem.

1.Lowertheloaderarms,stoptheengine,andremove

thekey.

2.Lift/supportthesideoftheunittobeworkedon

sothatthetrackis3to4inches(7.6to10cm)off

oftheground.

3.Removethelockingboltandnut(Figure41).

4.Usinga1/2inchdrivesocketwrench,release

thedrivetensionbyturningthetensioningscrew

clockwise(Figure41andFigure42).

32

Loading...

Loading...