Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Beforeeachuseordaily

•Greasethetrencher.

•Inspectthediggingteethandchainforexcessivewear.

Every25hours

•Checkthegearlubelevel.

•Adjustthediggingchaintension.

•Inspecttheboomforwear.

Every200hours

•Changethegearlube.

Beforestorage

•Greasethetrencher.

•Checkthegearlubelevel.

•Paintchippedsurfaces.

Ifyouleavethekeyintheignitionswitch,someonecouldstarttheengine.Accidentalstartingofthe

enginecouldseriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionswitchbeforeyoudoanymaintenance.

GreasingtheTrencher

ServiceInterval:Beforeeachuseordaily

Beforestorage

Grease2ttings,asshowninFigure8andFigure9,

everydayandimmediatelyaftereverywashing.

GreaseType:General-purposegrease

1.Stoptheengineandremovethekey.

2.Cleanthegreasettingswitharag.

3.Connectagreaseguntoeachtting.

4.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

5.Wipeupanyexcessgrease.

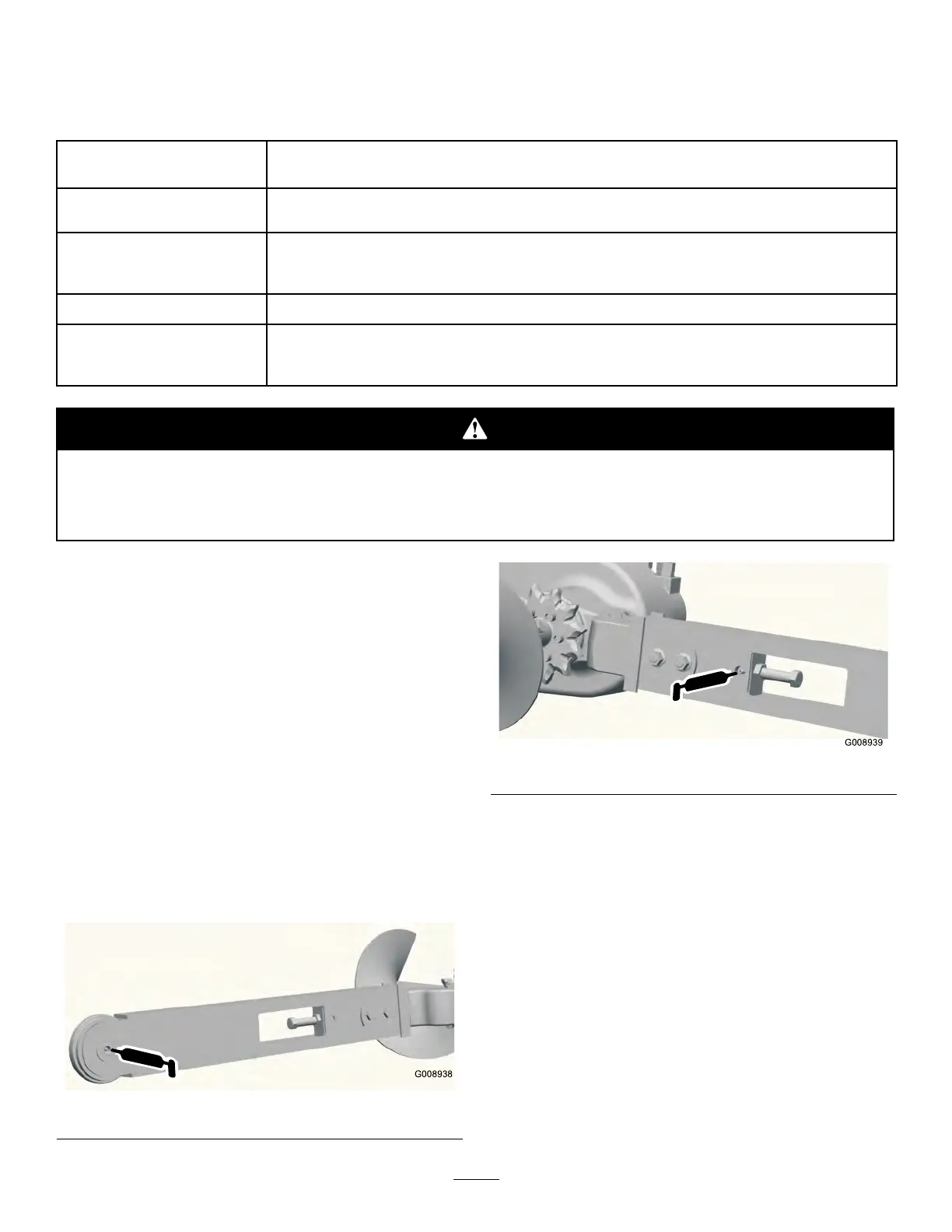

Figure8

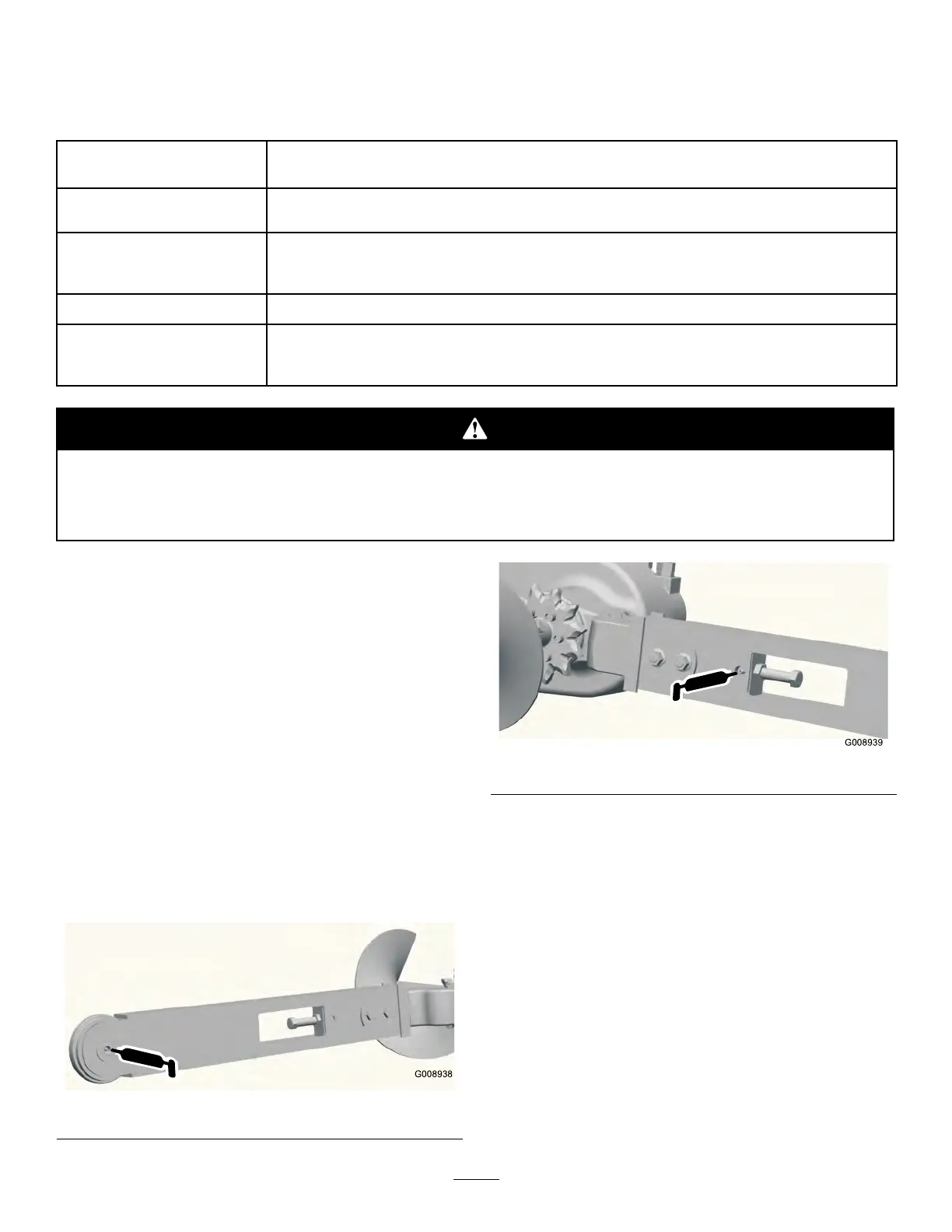

Figure9

ServicingtheBearingCase

Lube

ServiceInterval:Every25hours

Every200hours

Beforestorage

Gearlubetype:SAE90-140APIserviceGL-4orGL-5

Rellcapacity:1pint(1/2l).

CheckingtheBearingCaseLube

1.Lowerthetrenchertothegroundonaat,level

surfaceandtiltitsothattheboomisparallelwith

theground.

11

Loading...

Loading...