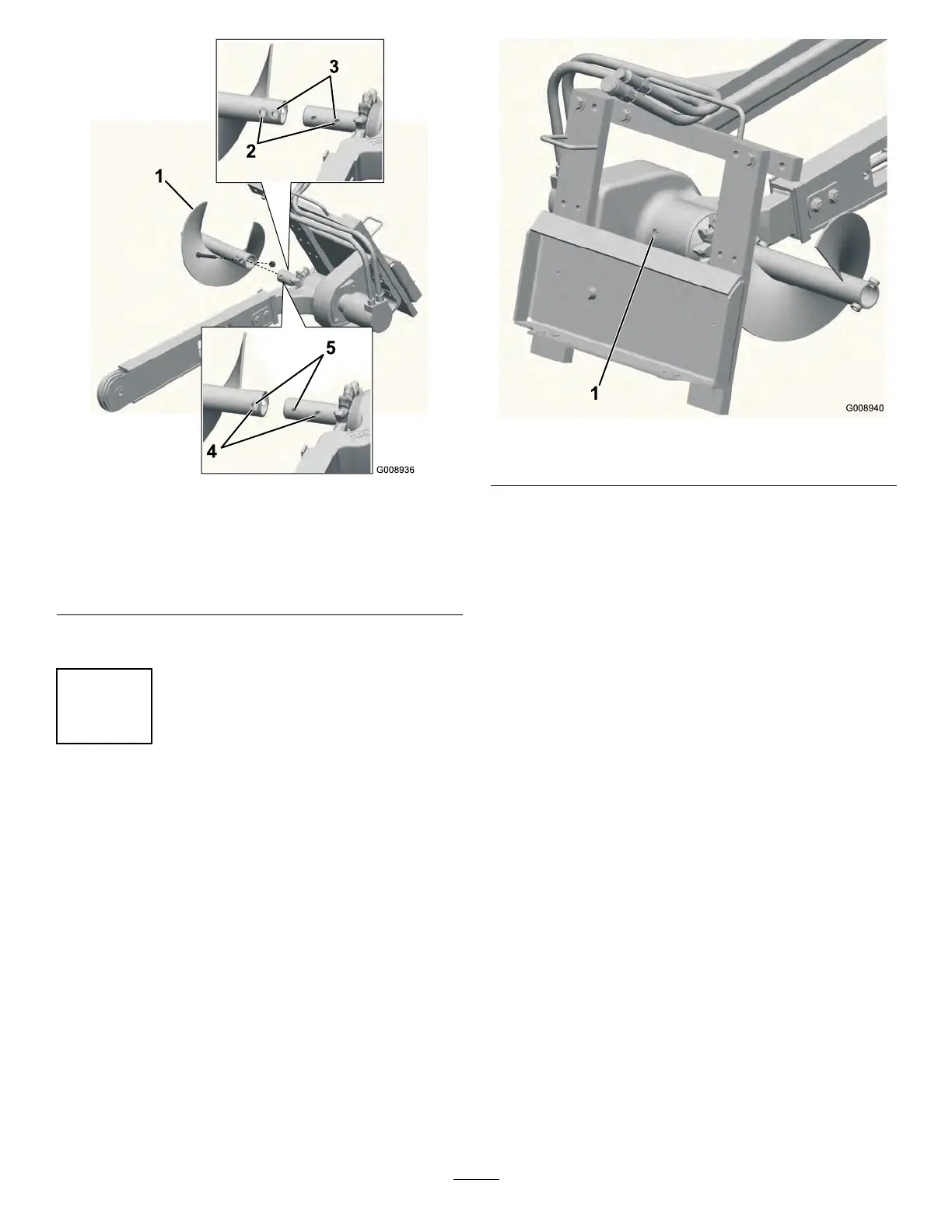

Figure5

1.Auger

2.Connecttheseholesfora4inch(10cm)chain

3.Connecttheseholesfora6inch(15cm)chain

4.Connecttheseholesfora8inch(20cm)chain

5.Connecttheseholesfora12inch(30cm)chain

2.Torquetheboltandnutto75ft-lb(101N-m).

4

CheckingtheBearingCase

LubeLevel

NoPartsRequired

Procedure

Beforeoperatingthetrencher,checktoensurethatthe

bearingcaseislledwithgearlube.

1.Lowerthetrenchertothegroundonaat,level

surfaceandtiltitsothattheboomisparallelwith

theground.

2.Stoptheengineandremovethekey.

3.Cleantheareaaroundthebearingcasellholeplug

(Figure6).

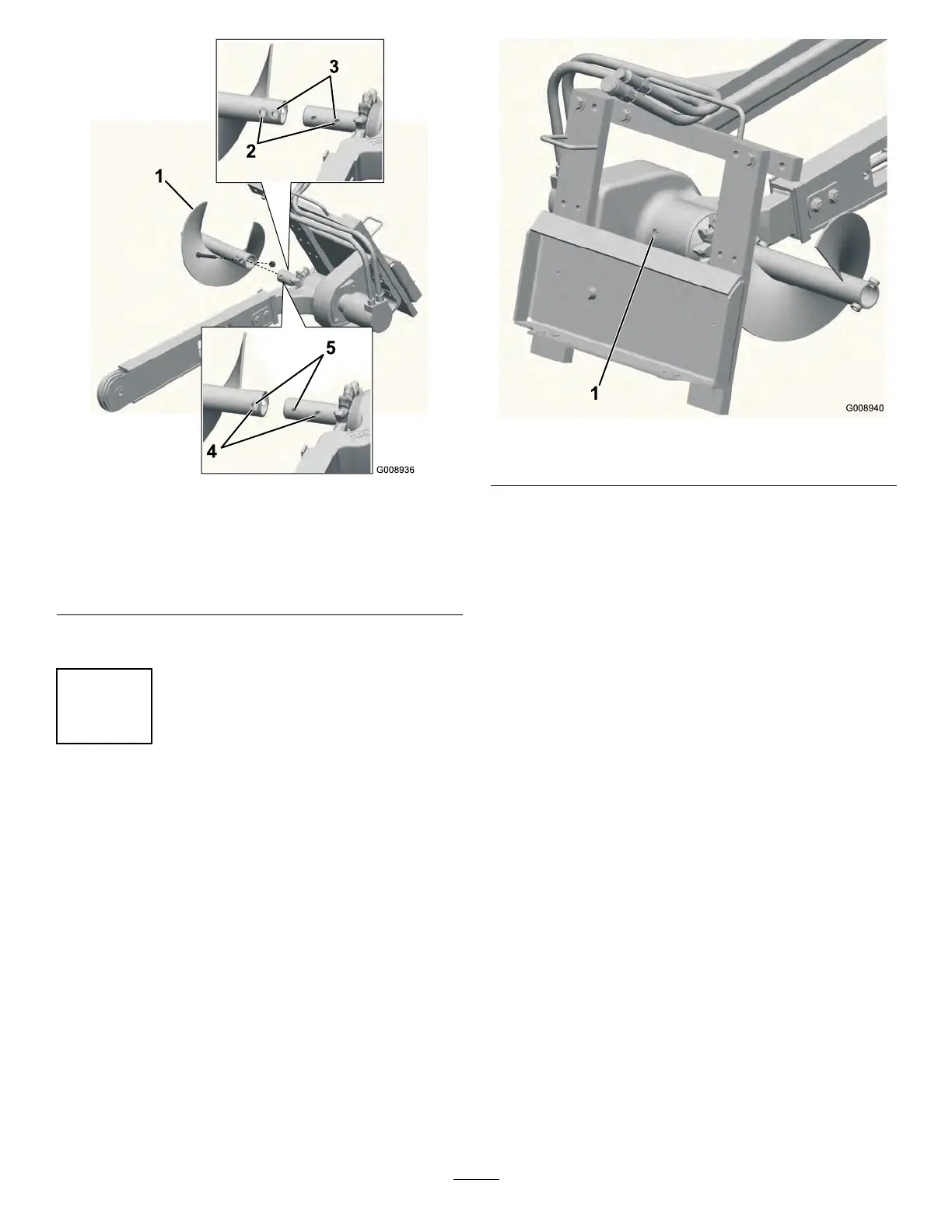

Figure6

1.Bearingcasellholeplug

4.Removetheplugfromthebearingcasellhole

(Figure6).

5.Lookinthehole,thelevelshouldbeuptothe

bottomofthehole;ifnotaddgearlubeuntilit

comesoutofthehole.

6.Replacetheplugandtorqueitto15to17ft-lb(20

to23N-m).

8

Loading...

Loading...