23

5. Carefully slide the foam element off the paper element

(Fig. 26).

Cleaning the Foam Element

1. Wash the foam element in liquid soap and warm water.

2. When the element is clean, rinse it thoroughly.

3. Dry the element by squeezing it in a clean cloth.

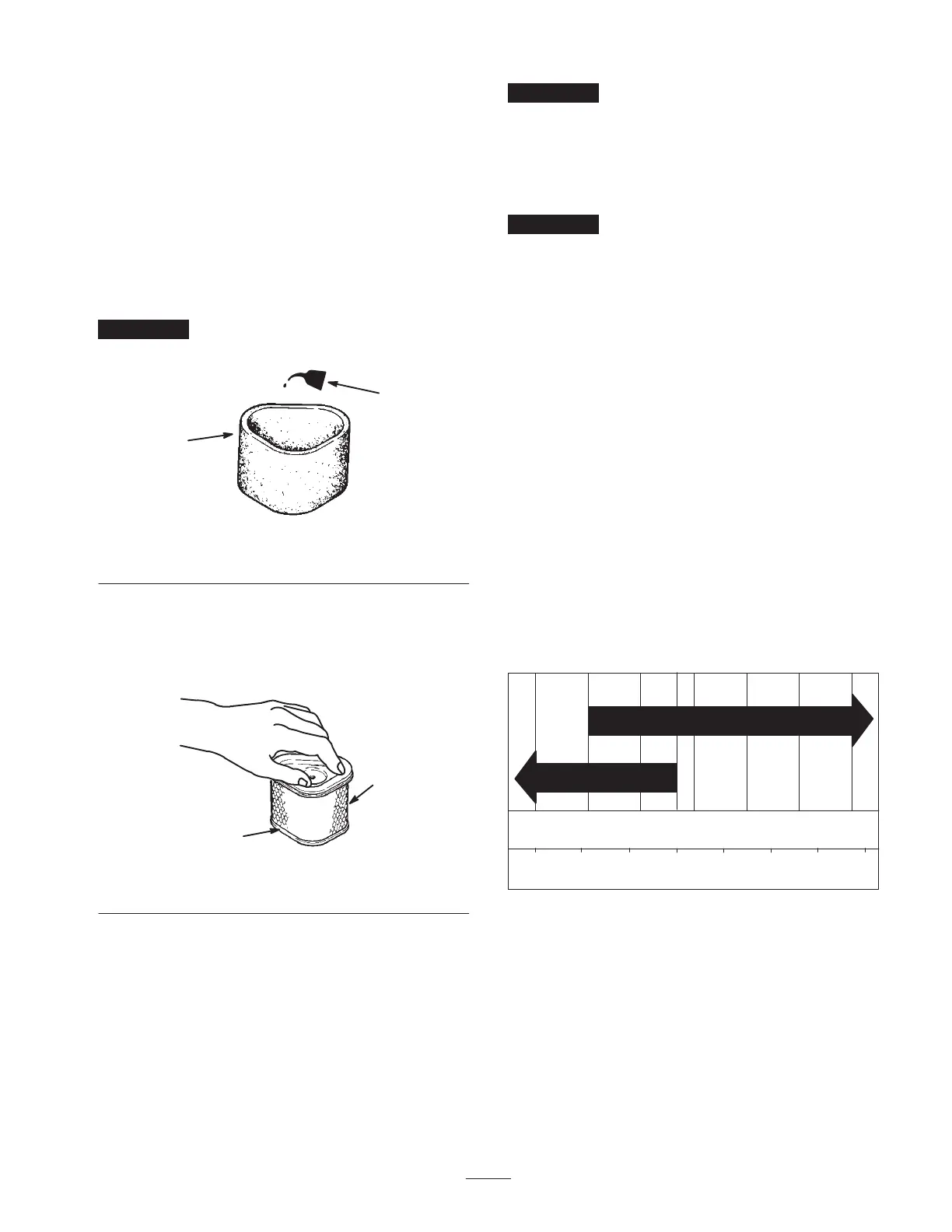

4. Put one or two ounces of oil on the element (Fig. 27).

5. Squeeze the element to distribute the oil.

Important Replace the foam element if it is torn or

worn.

2

m–5193

1

Figure 27

1. Foam element 2. Oil

Cleaning the Paper Element

1. Lightly tap the element on a flat surface to remove

dust and dirt (Fig. 28).

1

m–5192

2

Figure 28

1. Paper element 2. Rubber seal

2. Inspect the element for tears, an oily film, and damage

to the rubber seal.

Important Never clean the paper element with

pressurized air or liquids, such as solvent, gas, or

kerosene. Replace the paper element if it is damaged or

cannot be cleaned thoroughly.

Installing the Foam and Paper Elements

Important To prevent engine damage, always operate

the engine with the complete foam and paper air cleaner

assembly installed.

1. Carefully slide the foam element onto the paper air

cleaner element (Fig. 26).

2. Place the air cleaner assembly onto the air cleaner base

(Fig. 26).

3. Install the air cleaner cover and secure it with the

cover nut (Fig. 26).

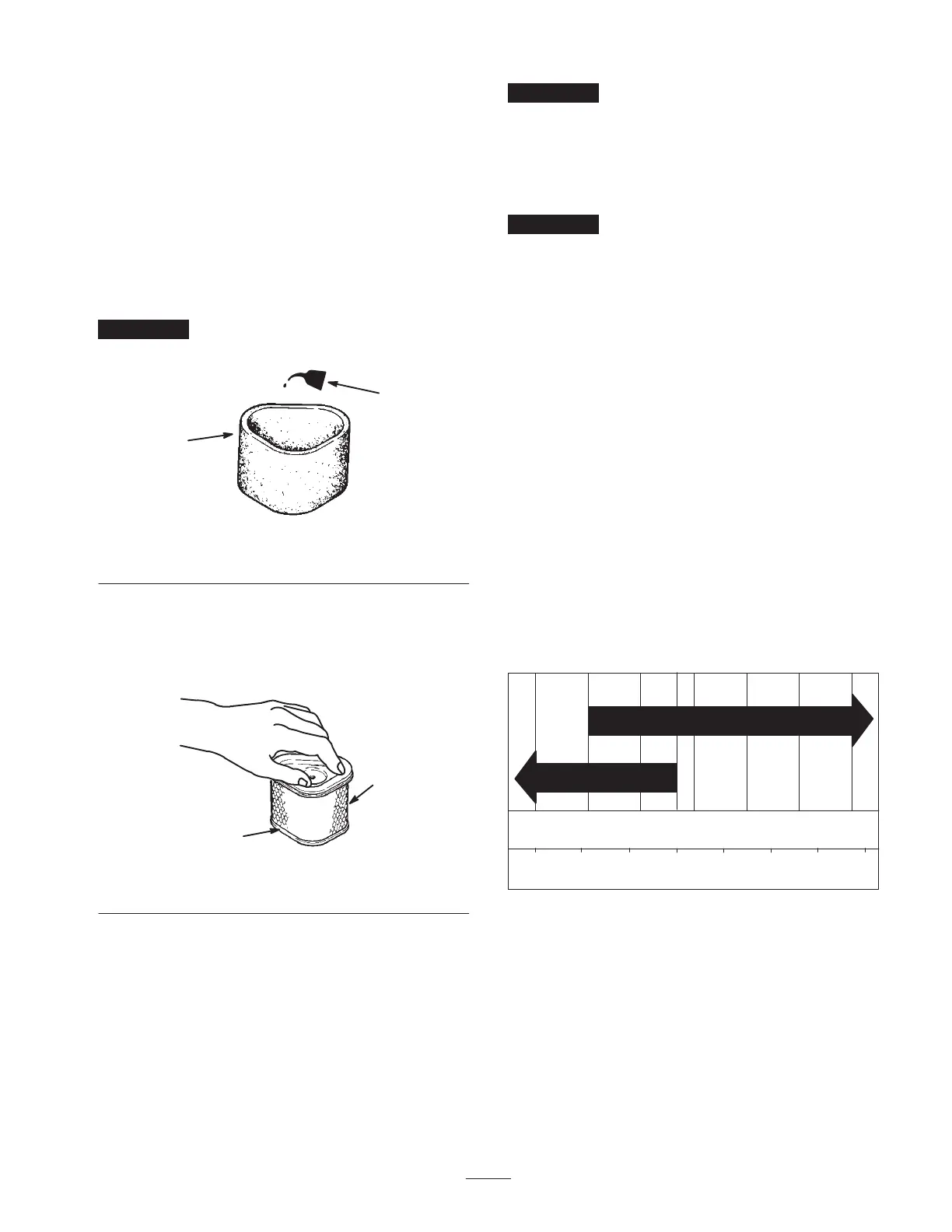

Servicing the Engine Oil

Change oil after the first 8 operating hours and then every

100 operating hours thereafter.

Note: Change oil more frequently when operating

conditions are extremely dusty or sandy.

Oil Type: Detergent oil (API service SF, SG or SH)

Crankcase Capacity: w/filter, 64 oz. (1.9 l)

Viscosity: See table below

F

–20 0 20

40 60

80 100

5

C

–30

5

–20 –10

01020

30 40

Use these SAE viscosity oils:

32

10W-30, 10W-40

5W-20, 5W-30

Checking the Engine Oil Level

1. Park the machine on a level surface, disengage the

blade control (PTO), set the parking brake, stop the

engine, remove the key, and disconnect the spark plug

wire from the spark plug.

Loading...

Loading...