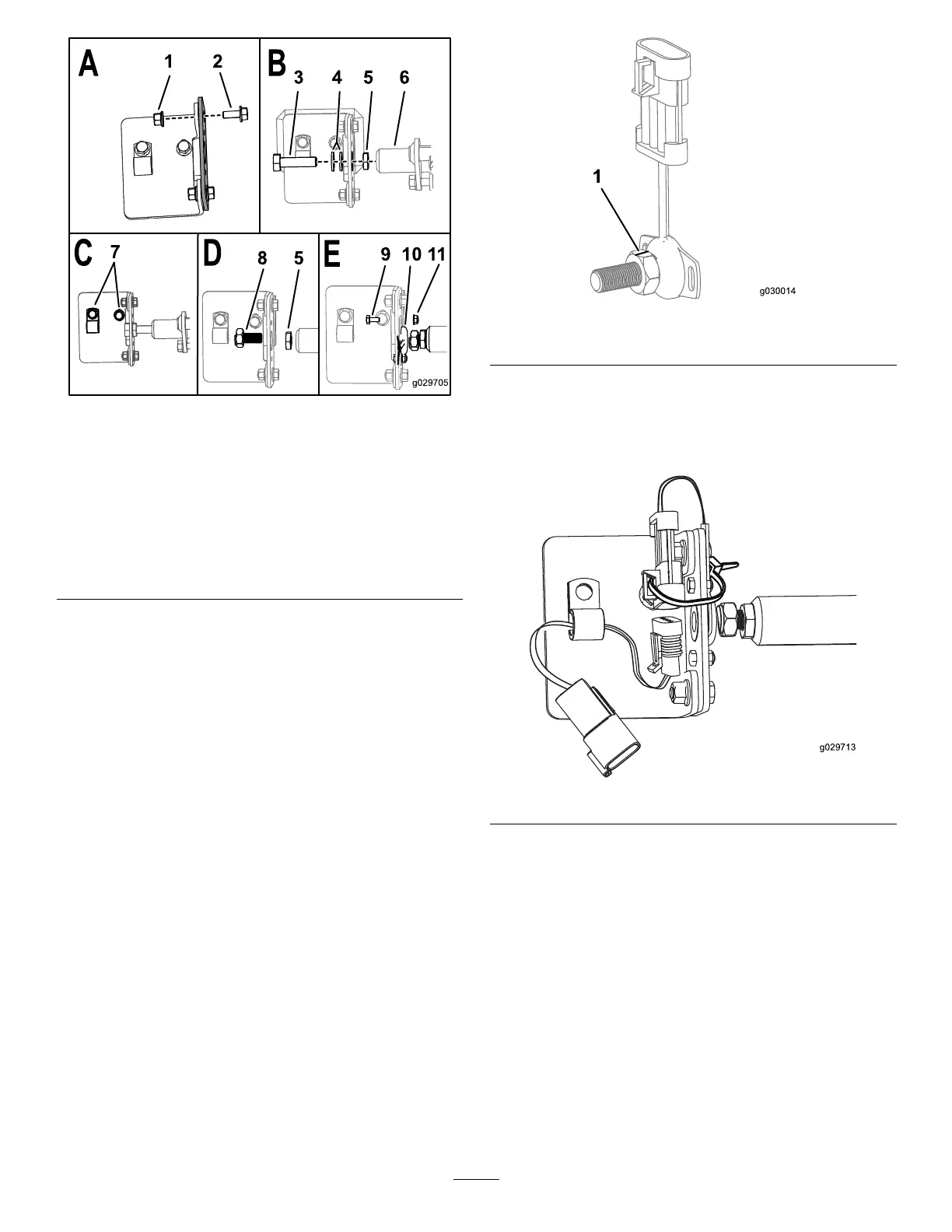

Figure7

1.Flangenut7.Applythread-locking

compoundwhen

tighteningthesebolts.

2.Bolts(M6–1x16mm)8.Sensor-magnetbolt

3.Bolt(M10–10x40mm)9.Bolt(M4x10mm)

4.Flatwashers

10.Sensor

5.Hexnut

11.Nut(M4)

6.Pivotpin

3.Installthebolt(M10-1x40mm),2atwashers,and

thehexnut(M10)ontothebracketplateandpivotpin

asshownBoxBofFigure7.

Note:Usethewasherstocenterthebracketandplate.

4.Tightenallofthehardwarethatissecuringthebrackets

tothemachine(BoxCofFigure7).

5.Torquetheboltsto972to1198N-cm(86to106in-lb).

6.Torquethebolts(M6)to972to1198N-cm(86to106

in-lb).

7.Removethebolt(M10–1x40mm),2atwashers,and

thehexnutfromthebracketplateandpivotpin(Box

BofFigure7).

8.Installthesensormagnetboltandhexnutintothe

pivotassemblyasshowninBoxDofFigure7.

9.Installthesensorontothebracketusing2bolts(M4

x10mm)and2nuts(M4–0.7inch)asshowninBox

EofFigure7.

Note:Usethread-lockingcompoundontheboltsif

thelocknutsarenotnylonlocknuts.

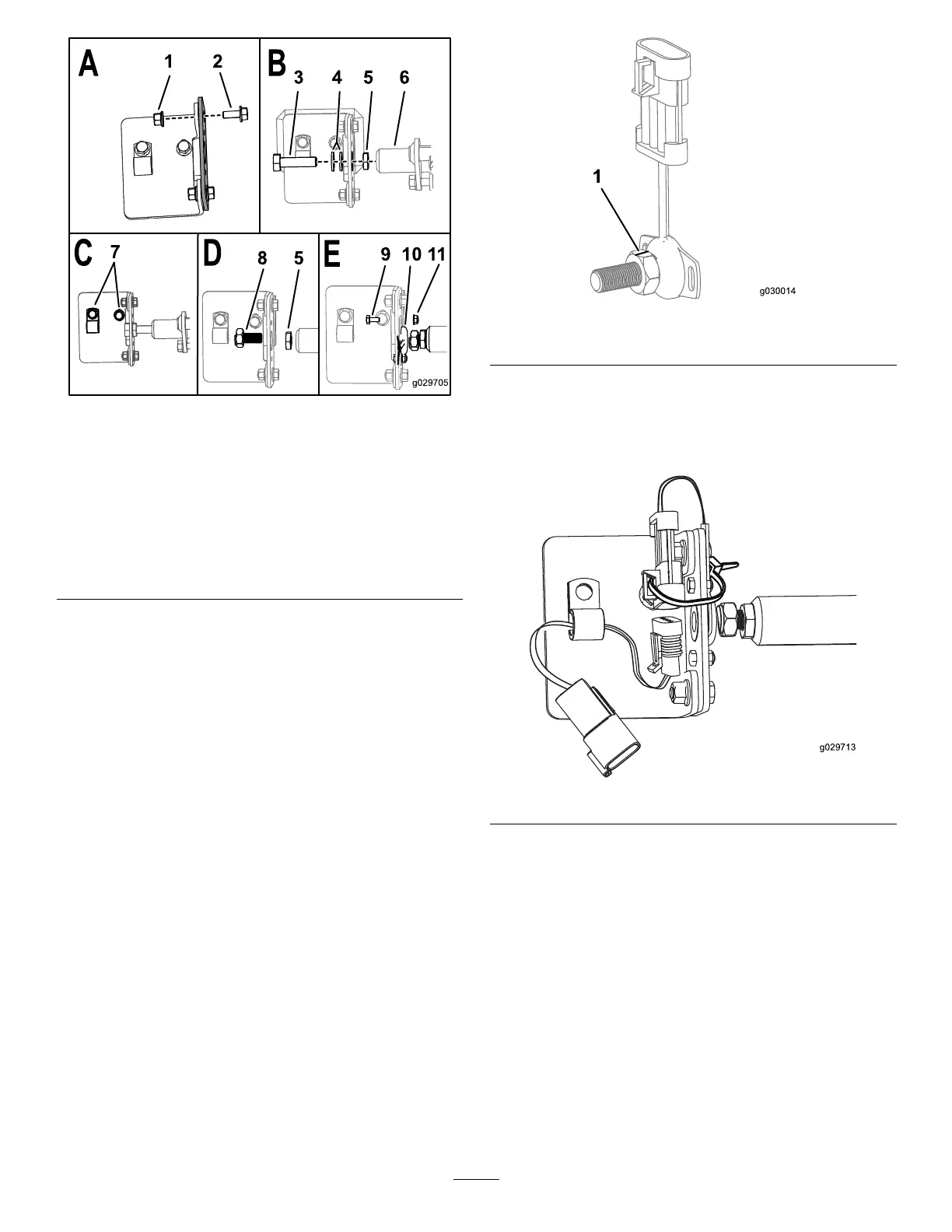

10.PlacethecamassemblyintheHOMEpositionand

ensurethatthenotchinthemagneticsensorboltis

linedupwiththewiresonthesensorasshownin

Figure8.

Figure8

1.Notch

11.Ensurethatthegapbetweenthemagneticsensorbolt

andthesensoris0.12to0.24inch.

12.Securethesensortothebracketwithacabletieas

showninFigure9.

Figure9

13.Torquethebolts(M4)to2.2to2.7N-m(19to23ft-lb).

14.Attachthesensor-harnessadaptertotheR-clampon

thebracketandattachtheadaptertothesensoras

showninFigure9.

15.Usethesensorharnessadaptertoconnectthesensor

tothewiringharnessofthemachine.

4

Loading...

Loading...