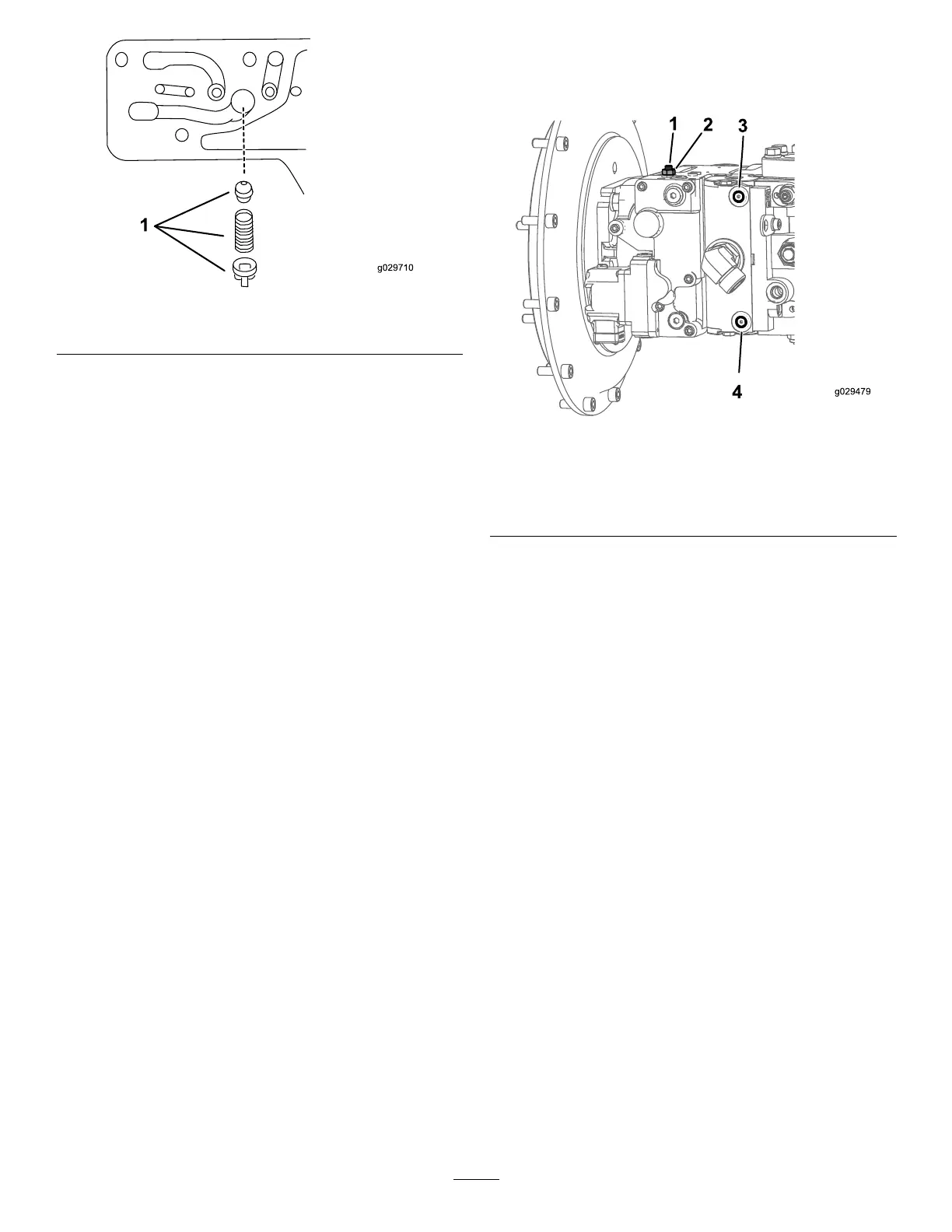

Figure19

1.T40,T30,andT20orices

8.Removethespring(T30)andsupplyorice(T20)from

thecontrol(Figure19).

9.Cleanthesealingsurfacesofthepumphousingand

controlhousing

10.Installthecontrolhousingontothepumpusingthe

newgasket.

Important:Thecontrollinkagepinonthecontrol

mustbeinsertedintotheswash-platelinkinthe

pump.

Note:Usepetroleumjellytohelpholdtheswash-plate

linkinplacewhilethecontrolisinstalled.

Note:Therewillberesistancewhenthefrontedge

ofthecontrolistiltedawayfromthepumphousingif

thecontrollinkagepinisinsertedintotheswash-plate

linkcorrectly.

Note:Ifthecontrollinkagepinisnotproperly

insertedintotheswash-platelink,thepumpwillnot

returntoneutralandtherotarymotorwillspinupon

enginestartup.

11.Installthe6retainingbolts;torquetheboltsto16N-m

(12lb-ft).

12.Connectthecasedrainlineandchecktheyhydraulic

uidlevel;refertotheOperator’sManualforthemachine.

13.Connectthewiringharnesstotherotarypumpcontrol.

14.Wipeupanyspilledoil.

15.Startthemachinetotesttherotarypump.

Note:Iftherotaryoutputspinswhenthemachine

isstartedbuttherotationcommandisnotgiven,the

controllinkagepinisnotproperlyinsertedintothe

swash-platelink.Removeandcapthecasedrainline

andrepeattheabovesteps.

CheckingtheNeutralAdjustment

1.Installa1000psigaugeineachofthedisplacement

controlports(M4andM5).

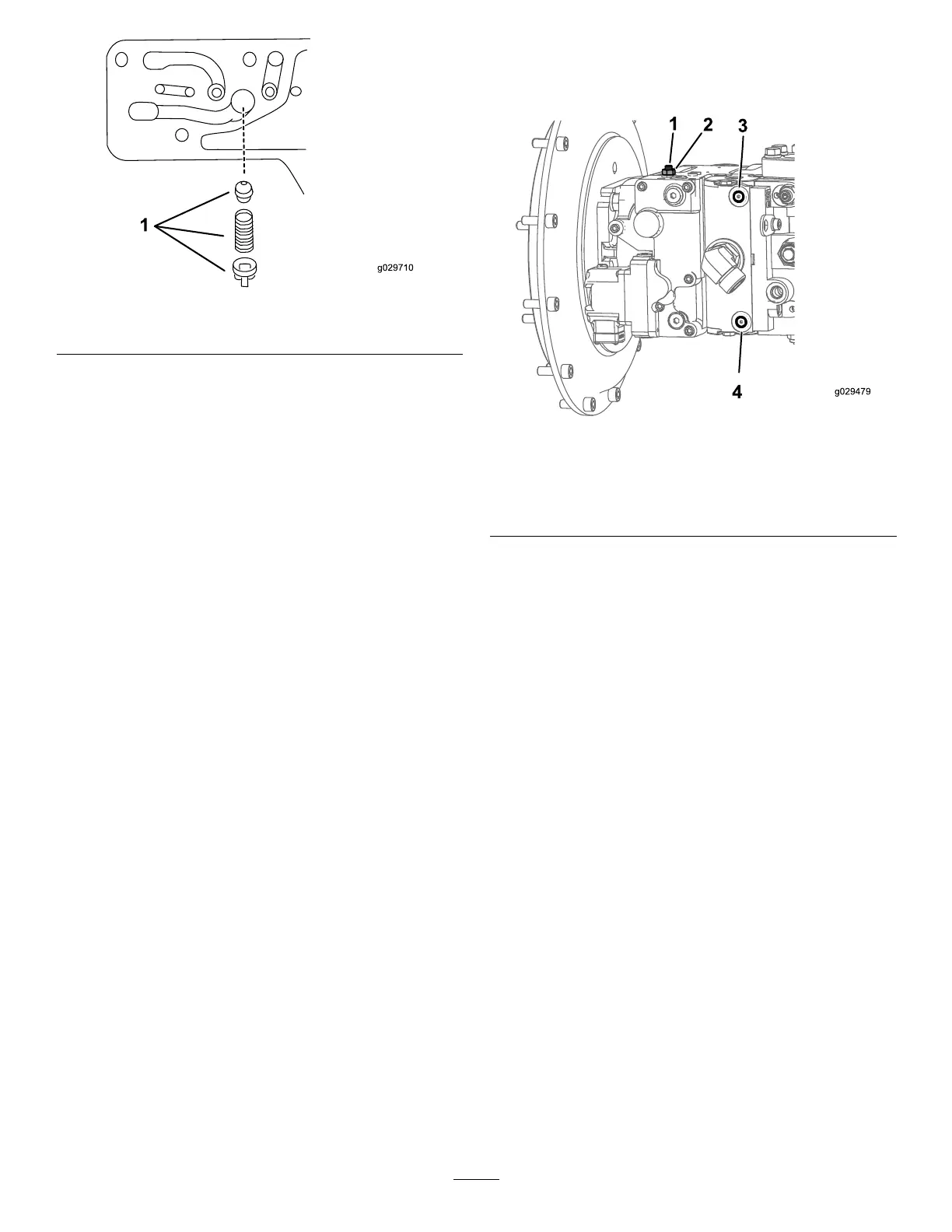

Figure20

1.M72port(adjustingscrew)3.M5port(displacement

controlport)

2.M90port(locknut)4.M4port(displacement

controlport)

2.Disconnecttheelectricalconnectorfromtherotary

pumpcontrol,startthemachine,andbringittohigh

idle.

3.Loosenthelocknut(M90)witha10mmand13mm

hexwrench.

4.Usinga3mmor4mminternalhexwrench,rotate

theadjustingscrew(M72)clockwiseuntilthepressure

increasesin1ofthepressuregauges.

Note:Notetheangularpositionofthewrench.

5.Rotatetheneutral-adjustingscrewcounterclockwise

untilthepressureincreasesbyanequalamountasthe

othergauge.

Note:Notethepositionofthewrench.

6.Rotatetheadjustingscrew(M72)clockwisehalfthe

distancebetweenthelocationnotedinstep(4or5).

Note:Thegaugesshouldreadthesamepressure(case

pressure),indicatingthatthecontrolisinitsNEUTRAL

position.

7.Holdtheneutral-adjustingscrewstationaryandtighten

theneutral-adjustinglocknutto7N-m(62lb-in)forthe

6mmscrewor13N-m(120lb-in)forthe8mmscrew .

8.OncetheNEUTRALpositionisset,stoptheengine,

removethegauges,andremovethegaugeports.

9.Connecttheelectricalconnectortotherotarypump

control.

8

Loading...

Loading...