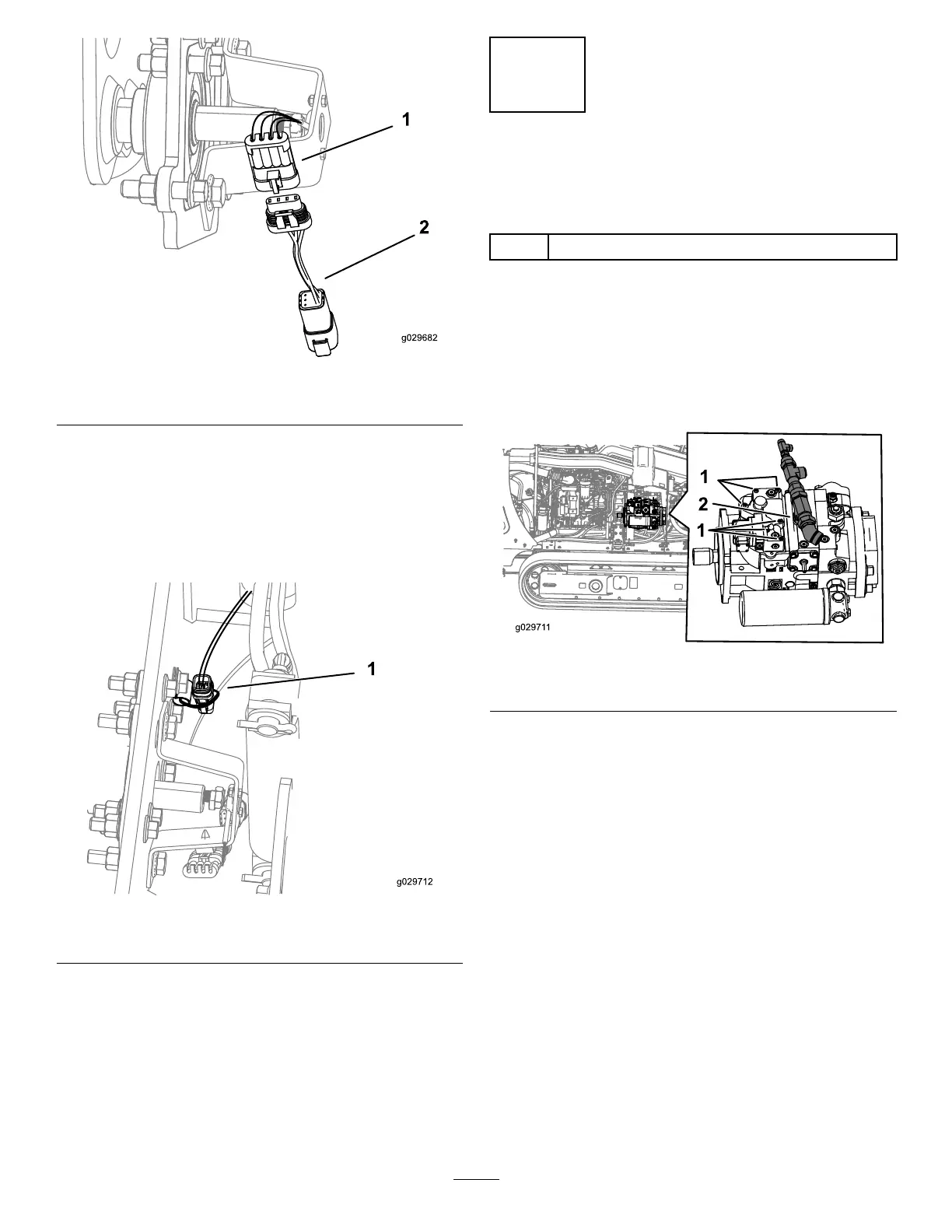

Figure16

1.Sensor2.Sensor-harnessadapter

16.Attachthesensor-harnessadaptertothesensoras

showninFigure16.

17.Connectthesensor-harnessadaptertothewiring

harnessonthemachine.

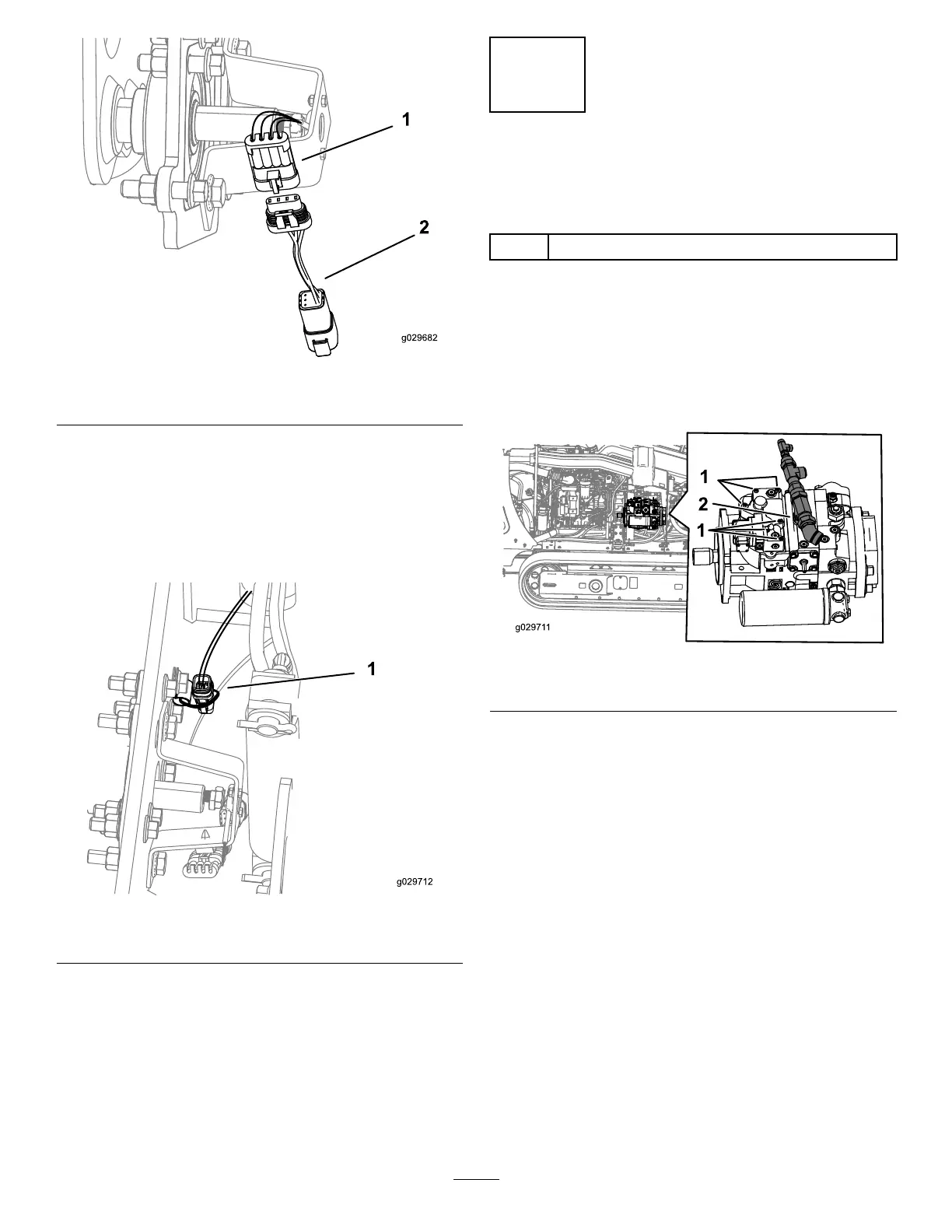

18.SecurethewiringharnesstotheR-clampwithacable

tieasshowninFigure17.

Figure17

1.Wiringharness(existing)

19.Torquetheboltsto2.2to2.7N-m(19to23in-lb).

20.Installtheelevatorcylinderwiththe2cotterpins

includedinthiskitasshowninBoxCofFigure13.

21.Usethesensorharnessadaptertoconnectthesensor

tothemachineswiringharness.

4

RemovingtheRotaryPump

SupplyandDrainOrices

Partsneededforthisprocedure:

1

Gasket

Procedure

Important:Allowtheenginetocool.

1.Placeadrainpanundertheyrotarypump

2.Capoffthecasedrainlinefromtherotarypumpto

minimizehydraulicuidloss.

Figure18

1.Boltstoberemoved

2.Capoffthecasedrainline

3.Cleantheexternalsurfaceoftherotarypump.

4.Unplugthewiringharnessfromthepumpcontrol.

5.Removethe6boltsasshowninFigure18.

6.Removethecontrolfromthepumphousing.

Note:Oilwilldrainfromthecasewhenthehousing

isremoved.

7.Useneedlenoseplierstopulltheretainingclip(T40)

fromthecontrol(Figure19).

7

Loading...

Loading...