33

IMPORTANT! Check fuel lines and connections

every 400 hours. Inspect for deterioration,

damage, or loose connections.

FUEL FILTERS (Fig. 29)

The MULTI PRO

®

5500 is equipped with two fuel

filters. One is an in-line type located between the

fuel tank and fuel pump. The other is a threaded

filter located between the fuel pump and

carburetor. Replace filters every 400 hours of use.

In-line:

1. Remove the inlet and outlet hose clamps.

2. Disconnect the hoses and discard the filter.

3. Install new filter by connecting the hose from

the fuel tank to the inlet side and the hose from

the fuel pump to the outlet side.

4. Position the hose clamps and tighten.

Threaded:

1. Loosen and slide hose clamp down the fuel

line. Remove the line from the filter.

2. Use 15/16" wrench to remove filter from elbow

and discard old filter.

3. Thread new filter and tighten securely. DO

NOT OVERTIGHTEN.

4. Install fuel line to new filter and secure with

hose clamp.

Note: After replacing fuel filters start the engine

and check for leaks.

WARNING

Servicing the vehicle while the engine is

running or vehicle is not properly secured,

could result in personal injury or death.

Before servicing or making adjustments

to the vehicle, set parking brake, stop

engine, and remove key from the switch.

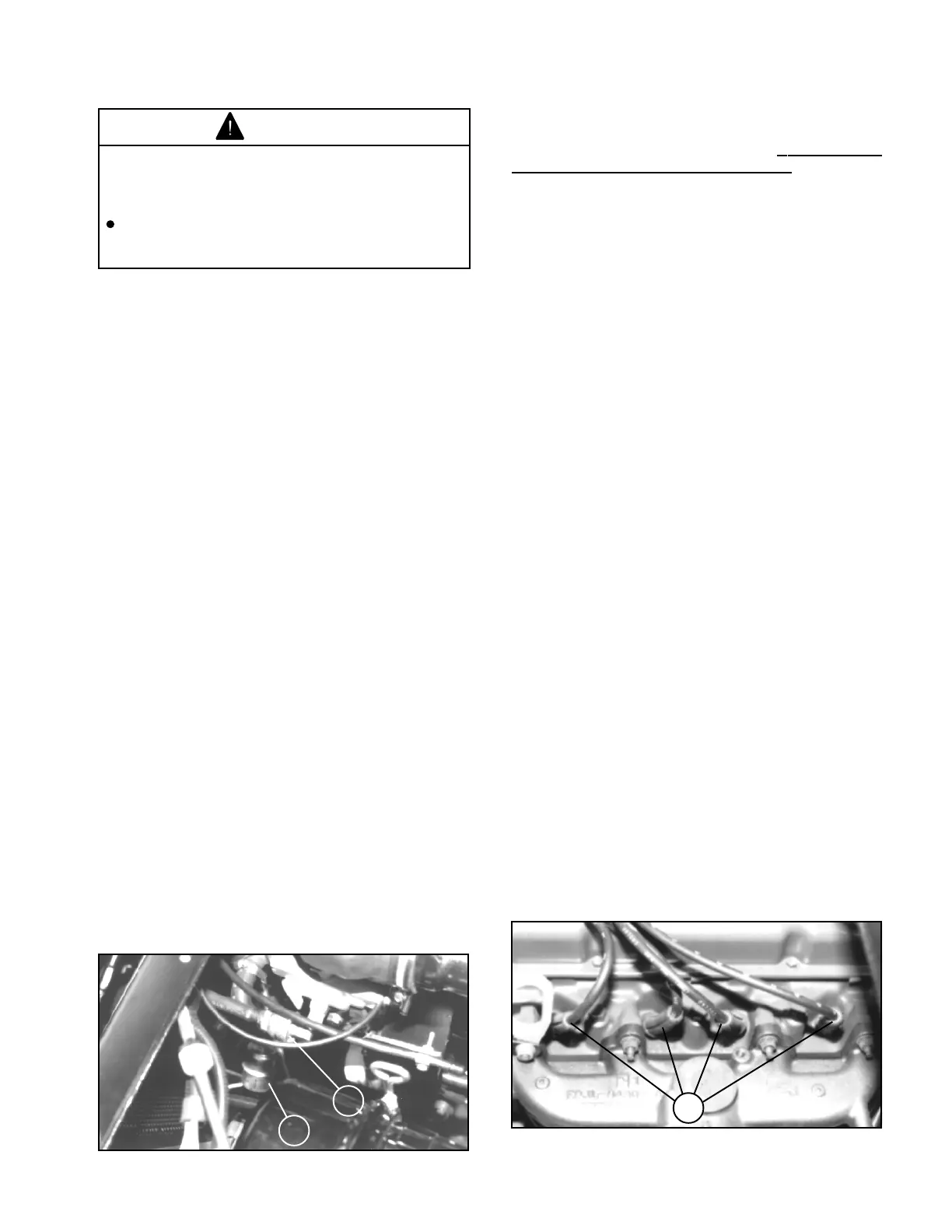

Figure 30

SPARK PLUGS (Fig. 30)

1. Spark Plugs

For specifications refer to the Ford Engine

Maintenance and Operator's Manual. (Supplied

with vehicle)

Replace spark plugs at recommended intervals.

Maintenance of spark plugs is an important factor

in assuring proper engine performance and

reducing the exhaust emission level.

The MULTI PRO

®

5500 uses Motorcraft-AGSF 22C

or AGRF22 or equivalent Spark Plugs with air gap

set as specified.

1. Remove wires from each Spark Plug by

grasping, twisting, and then pulling the molded

boot of the wire only. Do not pull directly on the

wire because the wire connection inside the boot

may become separated.

2. After loosening each Spark Plug one or two

turns, clean the area around each Spark Plug port

with compressed air, then remove Spark Plugs.

3. Check condition of side electrode, center

electrode, and center electrode insulator. Replace

spark plugs if damage is evident.

IMPORTANT! A CRACKED, FOULED, DIRTY,

OR OTHERWISE MALFUNCTIONING SPARK

PLUG MUST BE REPLACED. DO NOT

ATTEMPT TO SAND BLAST, SCRAPE, OR

CLEAN ELECTRODES WITH A WIRE BRUSH

BECAUSE GRIT MAY EVENTUALLY RELEASE

FROM THE PLUG AND CAUSE ENGINE

DAMAGE.

4. Set gap between center and side electrodes

as specified. Install correctly gapped Spark Plug

and torque (tighten) plug as specified.

5. Connect Spark Plug wires securely.

NOTE: Do not overtighten plugs. The gap may

change considerably due to the distortion of

the plug outer shell.

1. Inline filter 2. Threaded filter

Figure 29

ENGINE MAINTENANCE

Loading...

Loading...