RemovingtheBlades

Bladesmustbereplacedifasolidobjectishit,ifthe

bladeisoutofbalance,orifthebladeisbent.Toensure

optimumperformanceandcontinuedsafetyconformance

ofthemachine,usegenuineTororeplacementblades.

Replacementbladesmadebyothermanufacturersmayresult

innonconformancewithsafetystandards.

1.Holdthebladeendusingaragorathicklypadded

glove.

2.Removethebladebolt,thecurvedwasher,andthe

bladefromthespindleshaft(Figure79).

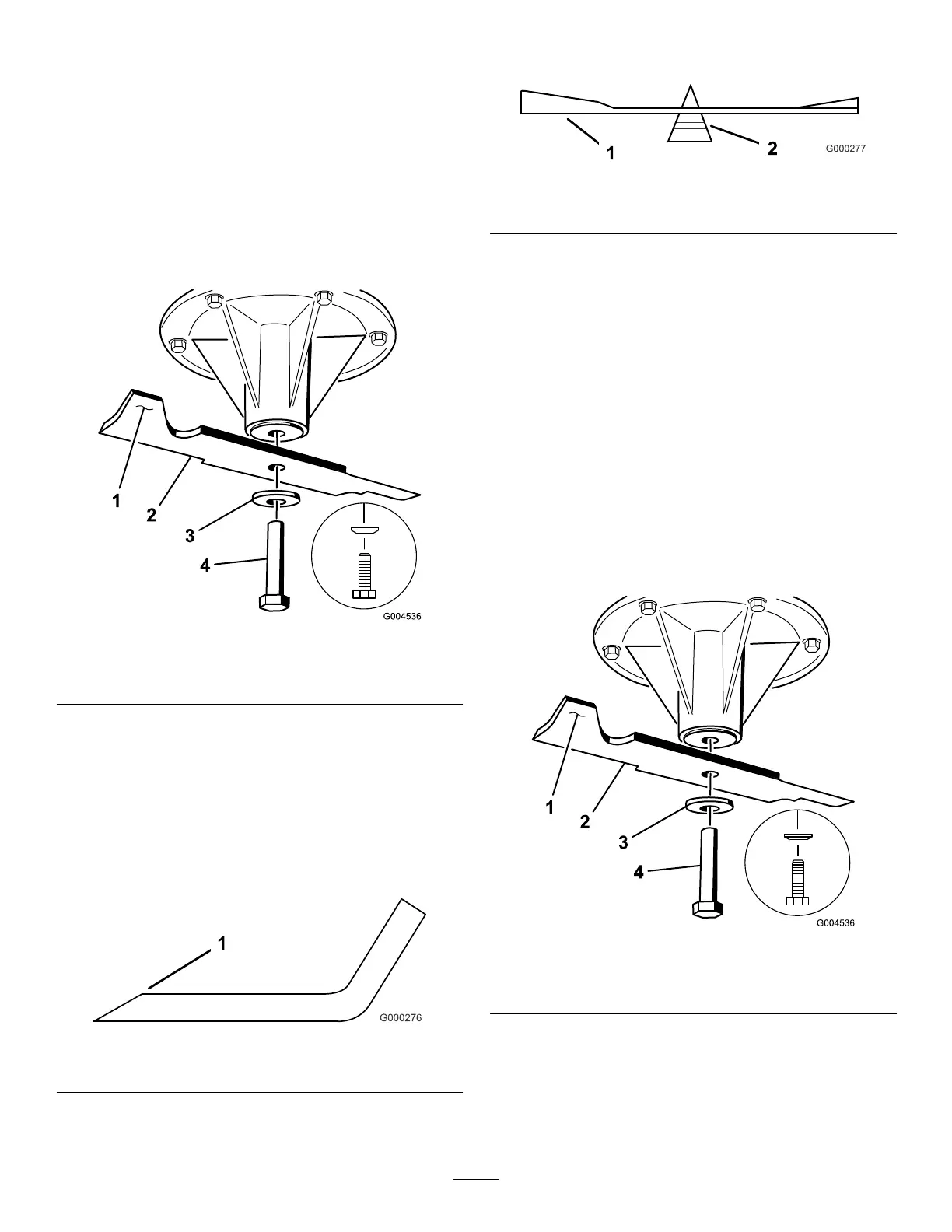

Figure79

1.Sailareaoftheblade3.Curvedwasher

2.Blade4.Bladebolt

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure80).

Note:Maintaintheoriginalangle.

Note:Thebladeretainsbalanceifthesameamount

ofmaterialisremovedfrombothcuttingedges.

Figure80

1.Sharpenattheoriginalangle

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure81).

Note:Ifthebladestaysinahorizontalposition,the

bladeisbalancedandcanbeused.

Figure81

1.Blade2.Balancer

3.Ifthebladeisnotbalanced,lesomemetalofftheend

ofthesailareaonly(Figure79).

4.Repeatthisprocedureuntilthebladeisbalanced.

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure82).

Important:Thecurvedpartoftheblademustbe

pointingupwardtowardtheinsideofthemowerto

ensurepropercutting.

2.Installthespringdiskandbladebolt(Figure82).

Note:Thespring-diskconemustbeinstalledtoward

thebolthead(Figure82).

3.Torquethebladeboltto115to150N-m(85to

110ft-lb).

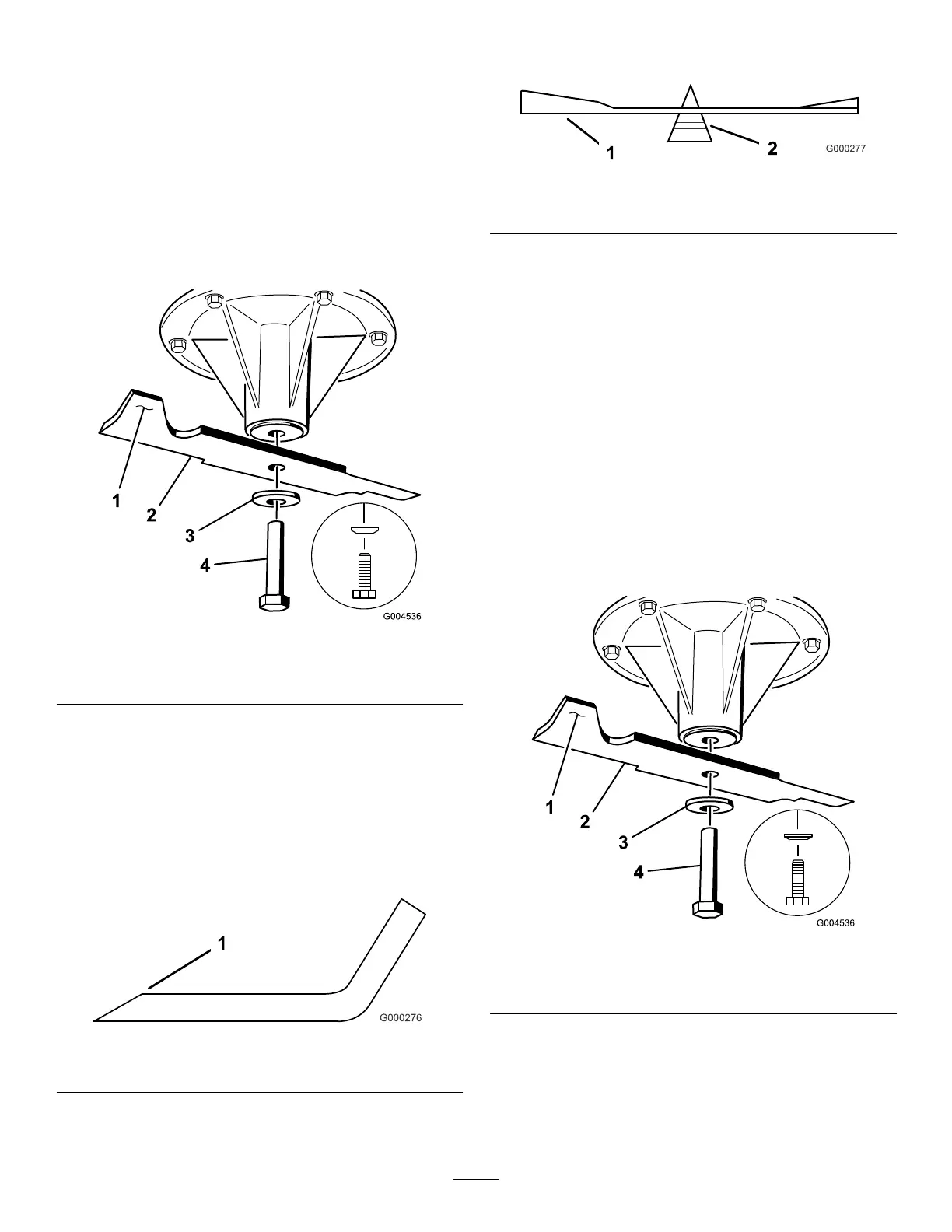

Figure82

1.Sailareaoftheblade3.Springdisk

2.Blade4.Bladebolt

53

Loading...

Loading...