AdjustingtheElectricClutch

ServiceInterval:Every500hours—Checktheelectric

clutch.

Theclutchisadjustabletoensureproperengagementand

properbraking.

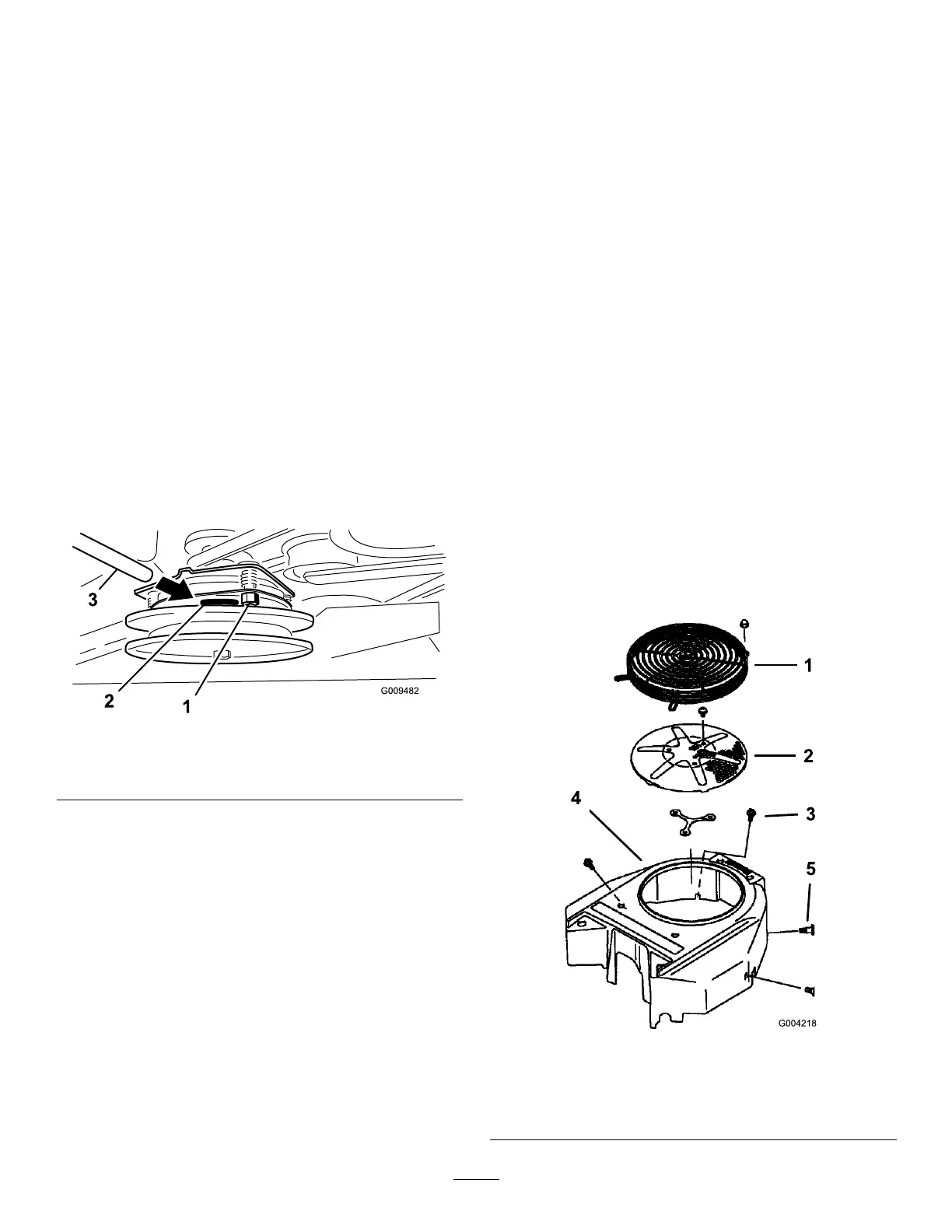

1.Inserta0.38to0.53mm(0.015–0.02inch)feelergauge

throughoneinspectionslotinthesideoftheassembly.

Note:Makesureitisbetweenthearmatureandthe

rotor-frictionsurfaces.

Note:Thegapneedstobeatleast0.38mm(0.015

inch),andnotmorethan0.53mm(0.02inch).

2.Ifadjustmentisneeded,thensetat0.38mm(0.015

inch)foreachofthethreeadjustmentslotpositions.

3.Tightenthelocknutsuntilthereisaslightbindingon

thefeelergauge,butitcanbemovedeasilywithinthe

airgap(Figure54).

4.Repeatthisfortheremainingslots.

5.Checkeachslotagainandmakeslightadjustmentsuntil

thefeelergaugebetweentherotorandarmaturewith

veryslightcontactbetweenthem.

Figure54

1.Adjustingnut3.Feelergauge

2.Slot

CoolingSystem

Maintenance

CleaningtheEngineScreen

ServiceInterval:Beforeeachuseordaily

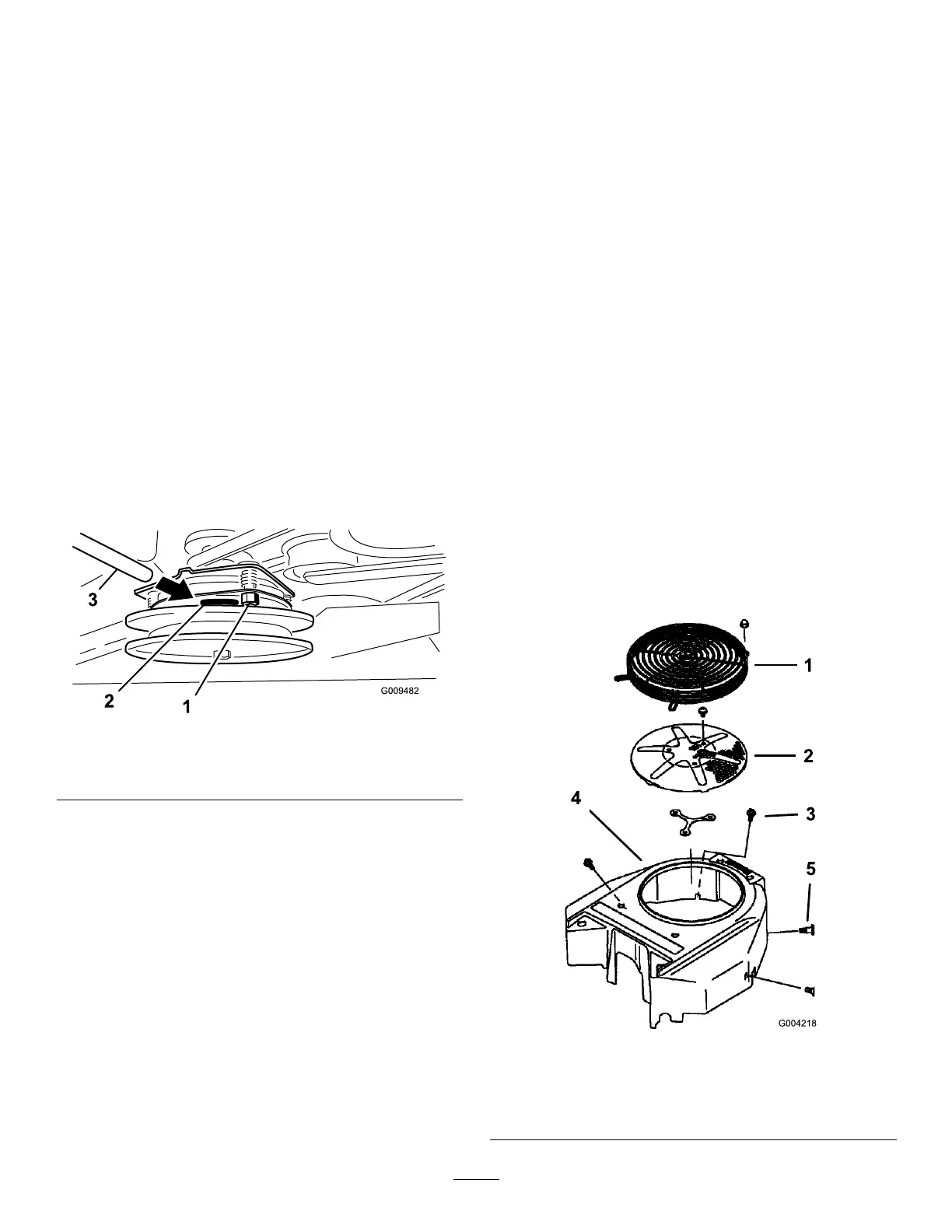

Beforeeachuseremoveanybuild-upofgrass,dirtor

otherdebrisfromtheenginescreen.Thiswillhelpinsure

adequatecoolingandcorrectenginespeedandwillreduce

thepossibilityofoverheatingandmechanicaldamagetothe

engine(Figure55).

CleaningtheEngineCooling

FinsandShrouds

ServiceInterval:Every100hours/Yearly(whichevercomes

rst)

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removetheairintakescreen,recoilstarterandfan

housing(Figure55).

4.Cleanthedebrisandgrassfromtheengineparts.

5.Installairintakescreen,recoilstarterandfanhousing

(Figure55).

Figure55

1.Engineguard4.Fanhousing

2.Engineairintakescreen

5.Screw

3.Bolt

42

Loading...

Loading...