Figure36

4.Installthebatteryinthemachineandconnectthe

batterycables;refertoInstallingtheBattery.

Note:Donotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance,however,ifafuseblowscheck

component/circuitformalfunctionorshort.

Thefusesareasfollows:

•MainF1-30amp,blade-type

•AlternatorF2-25amp,blade-type

1.Unlatchtheseatandraisetheseattogainaccessto

fuseholder(Figure37).

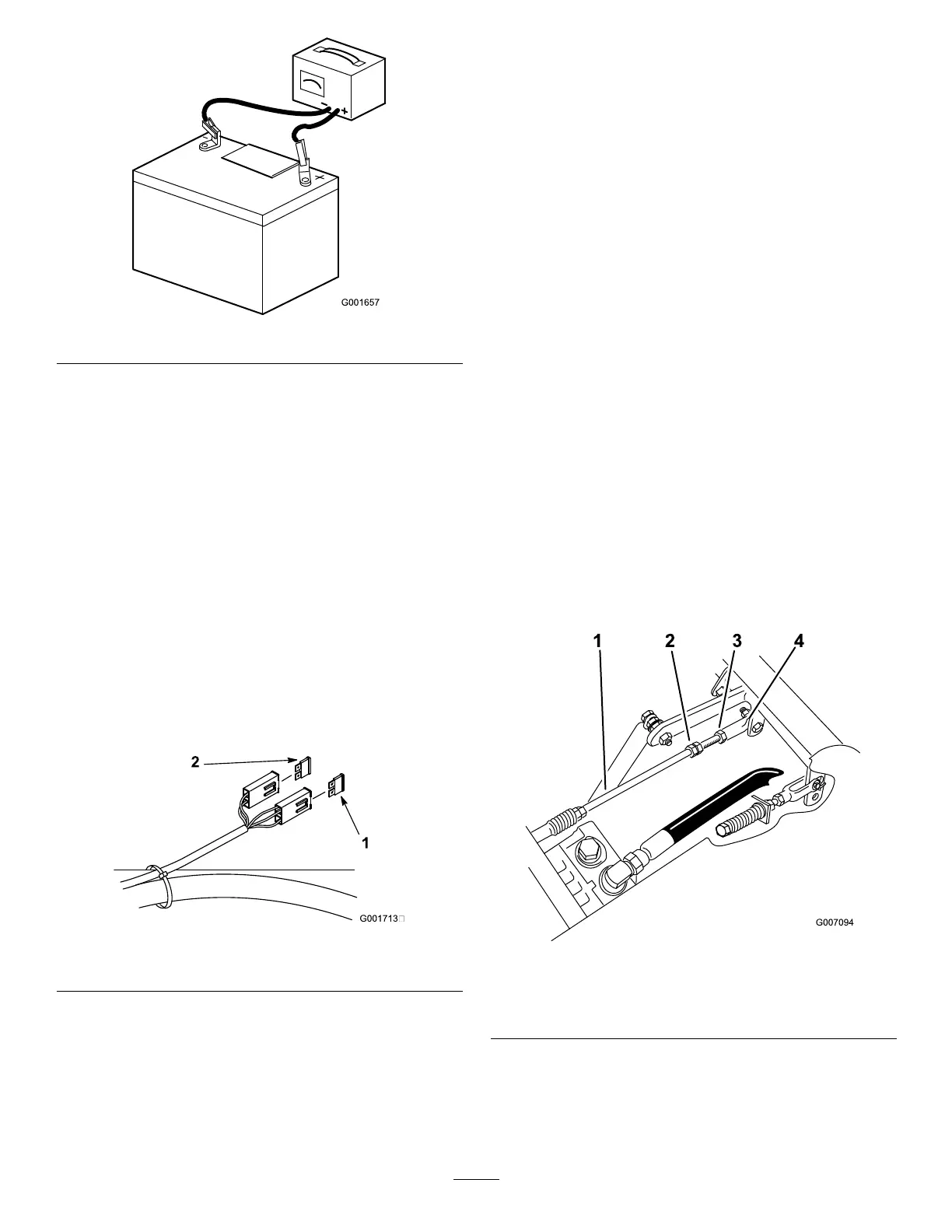

Figure37

1.MainF1-30amp2.AlternatorF2-25amp

2.Toreplacethefuses,pulloutonthefusetoremove

it.

3.Installanewfuse(Figure37).

DriveSystem

Maintenance

AdjustingtheTracking

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Note:Adjustthehandleneutralandhydraulicpump

neutralbeforeadjustingthetracking.RefertoAdjusting

theHandleNeutralandAdjustingtheHydraulicPump

Neutral.

1.Pushbothcontrolleversforwardthesamedistance.

2.Checkifthemachinepullstooneside.Ifitdoes,

stopthemachineandsettheparkingbrake.

3.Unlatchtheseatandtiptheseatuptoaccessthe

pumpcontrolrod.

4.Loosenthelocknutattheballjointonrighthand

pumpcontrolrod(Figure38).

•Tomakethemachinegoright,rotatethedouble

nutsonrodtotherightsideofthemachine.

•Tomakethemachinegoleft,rotatethedouble

nutsonrodtotheleftsideofthemachine.

5.Tightenthelocknutattheballjointandtestthe

tracking(Figure38).

6.Repeatthisadjustmentuntilthetrackingiscorrect.

Figure38

1.Righthandpumpcontrol

rod

3.Locknut

2.Doublenuts4.Balljoint

CheckingtheTirePressure

ServiceInterval:Every50hoursormonthly,whichever

occursrst.

33

Loading...

Loading...