Maintaintheairpressureinthefrontandreartiresat

13psi(90kPa).Uneventirepressurecancauseuneven

cut.Checkthetireswhentheyarecoldtogetthemost

accuratepressurereading(Figure39).

Figure39

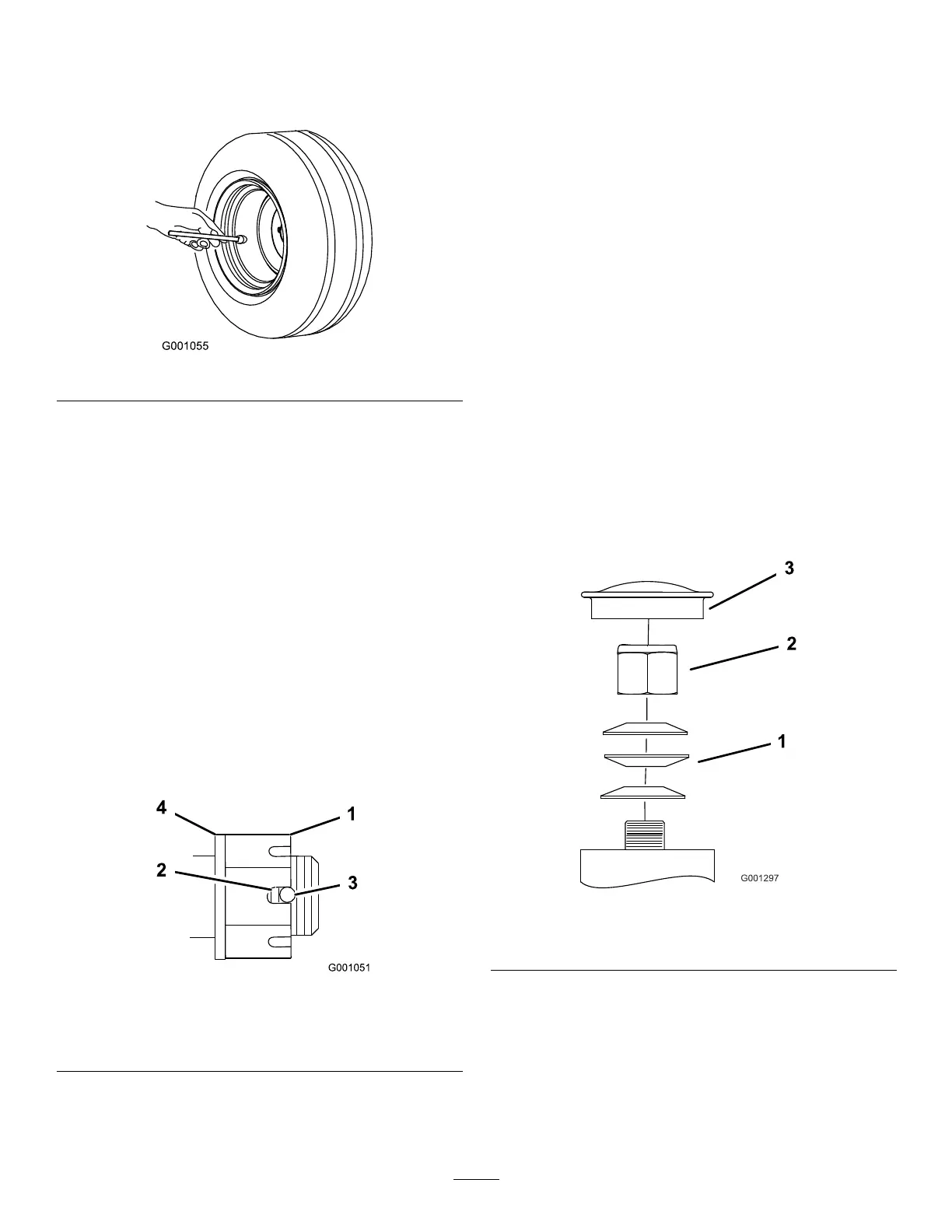

CheckingtheWheelHub

SlottedNut

ServiceInterval:Every100hours

Theslottednutneedstobetorquedto125ft-lb

(170N⋅m).

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removethecotterpin.

4.Torquetheslottednutto125ft-lb(170N⋅m)

(Figure40).

Figure40

1.SlottedNut3.Holeinthreadedshaft

2.Twothreadsorless

showing

4.Washer(ifneeded)

5.Checkthedistancefrombottomofslotinnutto

insideedgeofhole.Twothreadsorlessshouldbe

showing(Figure40).

6.Ifmorethantwothreadsareshowingremovenut

andinstallwasherbetweenhubandnut.

7.Torquetheslottednutto125ft-lb.(170N⋅m)

(Figure40).

8.Tightenthenutuntilthenextsetofslotslineupwith

theholeintheshaft(Figure40).

9.Replacethecotterpin.

AdjustingtheCasterPivot

Bearing

ServiceInterval:Every500hoursoratstorage,which

evercomesrst.

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removethedustcapfromcasterandtightenlock

nut(Figure41).

Figure41

1.SpringWashers3.DustCap

2.LockNut

4.Tightenthelocknutuntilthespringwashersareat

andthenbackoffa1/4turntoproperlysetthe

pre-loadonthebearings(Figure41).

Important:Makesurespringwashersare

installedcorrectlyasshowninFigure41.

5.Installthedustcap(Figure41).

34

Loading...

Loading...