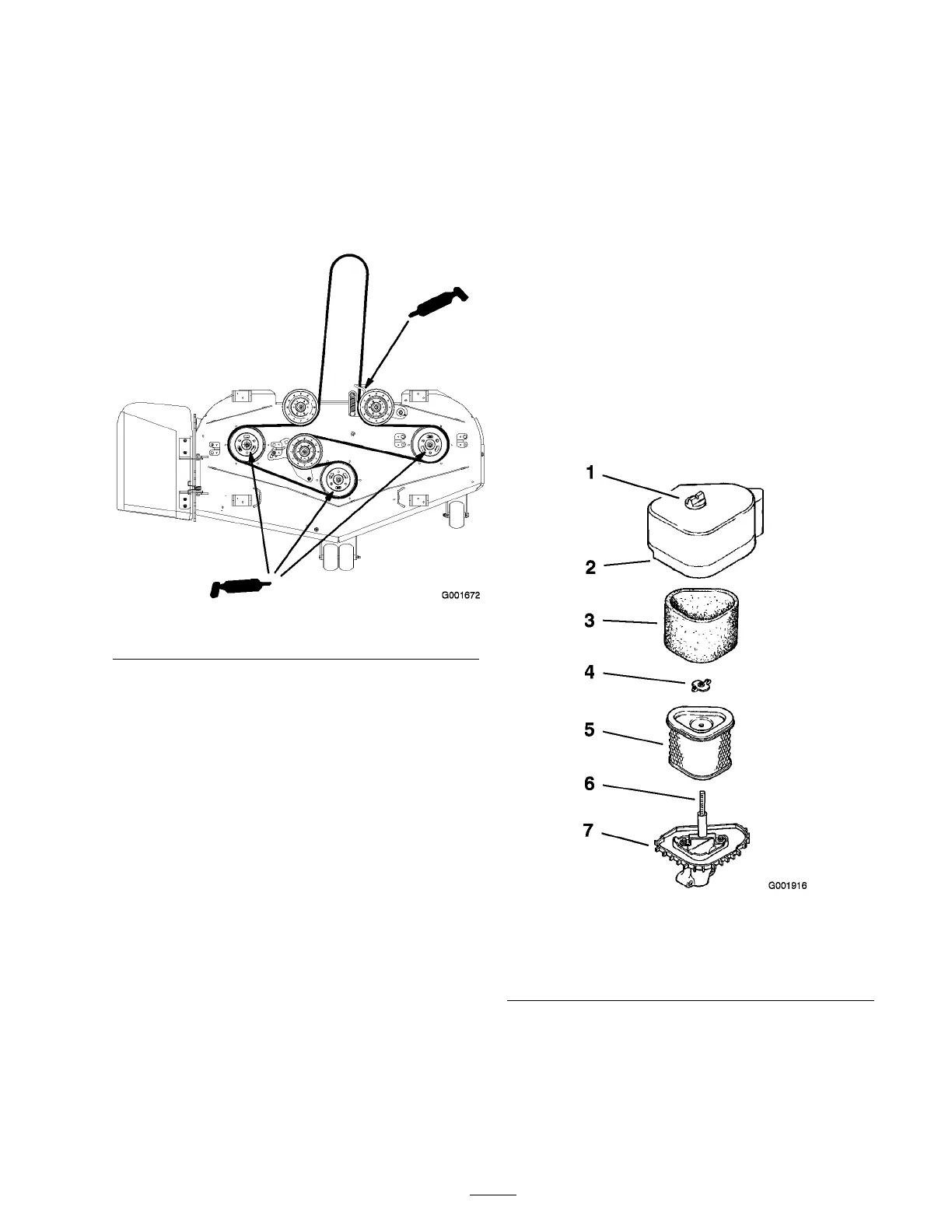

4. Grease the three spindle bearings under the

pulleys until g rease comes out the lo w er seals

( Figure 27 ).

5. Grease the idler ar m on the mo w er dec k

( Figure 27 ).

6. Grease the fittings on the push ar ms

( Figure 27 ).

Figure 27

Engine Maintenance

Servicing the Air Cleaner

Service Interval/Specication

F oam element: Clean it after ev er y 25 operating

hours .

P aper element: Chec k it after ev er y 50 operating

hours . R e place it after ev er y 200 operating hours

or yearly , whic h ev er comes first.

Inspect the foam and paper elements and re place

them if they are damag ed or ex cessi v ely dir ty .

Note: Ser vice the air cleaner more frequently

(ev er y few operating hours) if the operating

conditions are extremely dusty or sandy .

Important: Do not oil the f oam or paper

element.

Removing the Foam and Paper

Elements

1. Diseng ag e the PTO and set the parking brak e .

2. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

3. Clean around the air cleaner to prev ent dir t

from g etting into the engine and causing

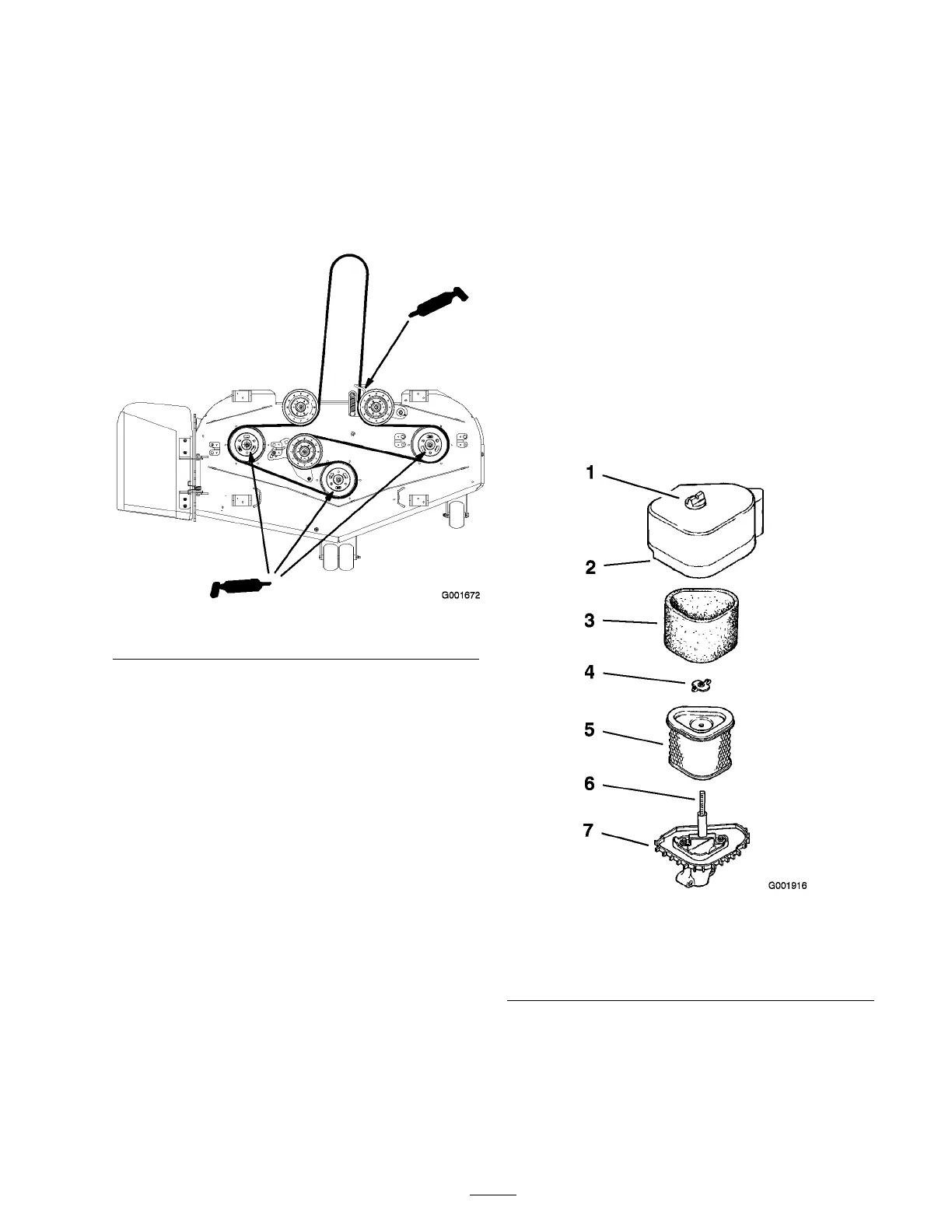

damag e ( Figure 28 ).

4. Unscrew the co v er knob and remo v e the air

cleaner co v er ( Figure 28 ).

5. R emo v e the wing n ut and remo v e the air

cleaner assembly ( Figure 28 ).

6. Carefully pull the foam element off the paper

element ( Figure 28 ).

Figure 28

1. Cover knob 5. Paper element

2. Cover

6. Stud

3. Foam element

7. Engine

4. Wing nut

Cleaning the Foam Air Cleaner

Element

1. W ash the foam element in liquid soap and

w ar m w ater . W hen the element is clean, rinse

it thoroughly .

27

Loading...

Loading...