2. Dr y the element b y squeezing it in a clean cloth.

Do not wring it as this ma y cause damag e .

3. Put oil on the element and squeeze it to

distribute the oil.

Important: R eplace the f oam element

if it is tor n or w or n.

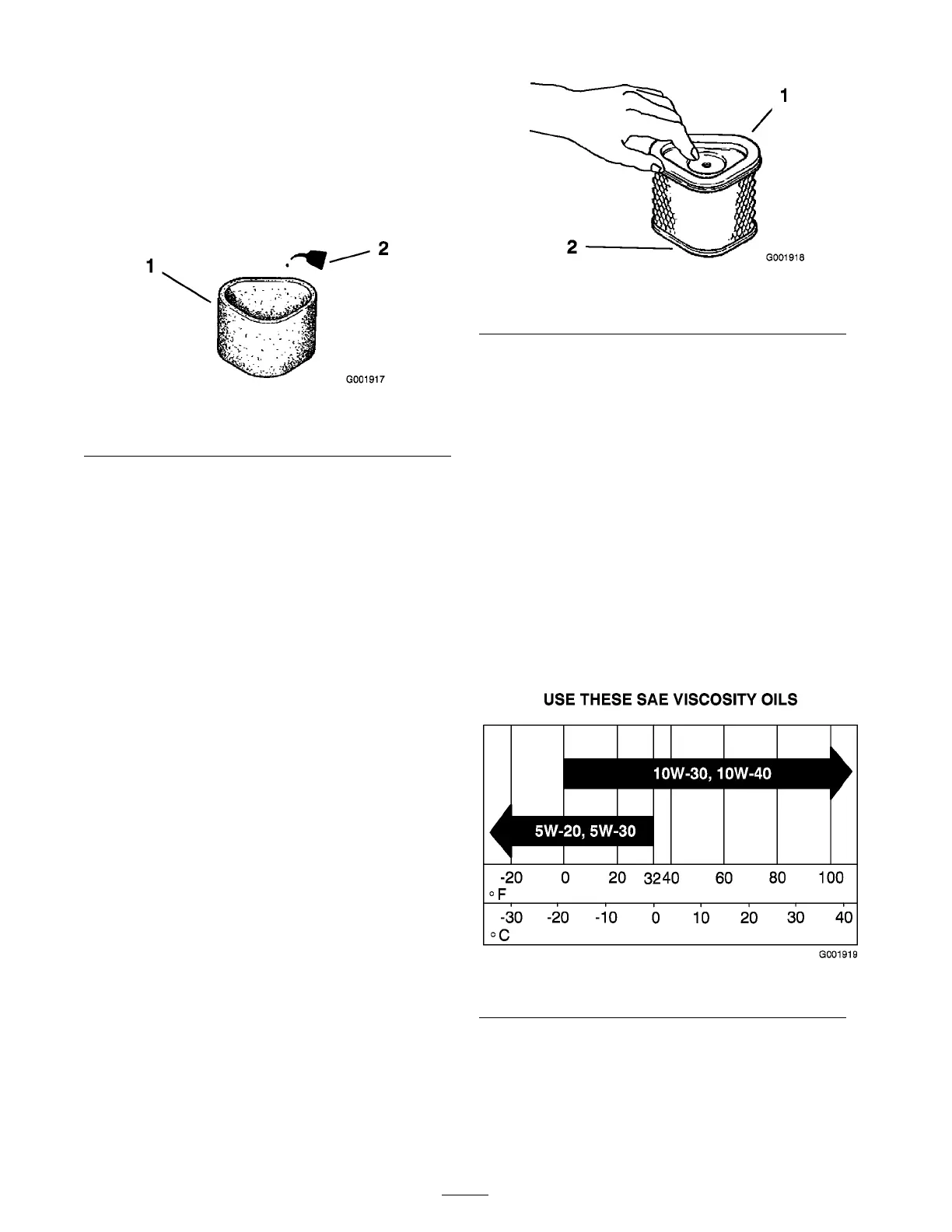

Figure 29

1. Foam element 2. Oil

Servicing the Paper Air Cleaner

Element

1. Do not clean the paper filter . R e place it after

100 operating hours ( Figure 28 ).

2. Inspect the element for tears , an oily film, or

damag e to the r ubber seal.

3. R e place the paper element if it is damag ed.

Installing the Foam and Paper

Elements

Important: T o pr ev ent engine dama ge,

al w ays operate the engine with the complete

f oam and paper air cleaner assembl y installed.

1. Carefully slide the foam element onto the

paper air cleaner element ( Figure 28 ).

2. Place the air cleaner assembly onto the air

cleaner base and secure it with the wing n ut

( Figure 28 ).

3. Place the air cleaner co v er into position and

tighten the co v er knob ( Figure 28 ).

Figure 30

1. Paper element 2. Rubber seal

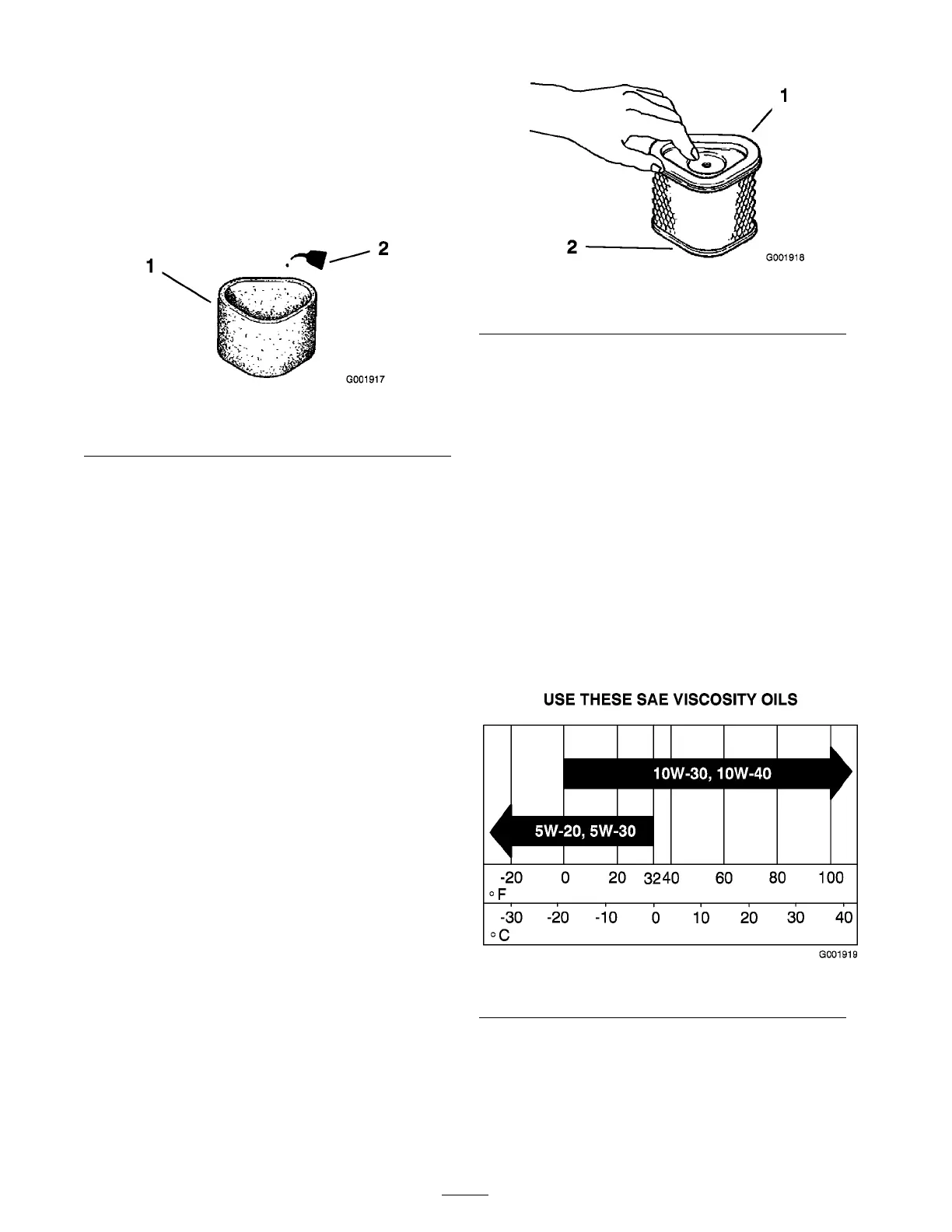

Servicing the Engine Oil

Service Interval/Specication

Chang e the engine oil as follo ws after ev er y

100 operating hours .

Note: Chang e the oil more frequently when the

operating conditions are extremely dusty or sandy .

Oil T ype: Deterg ent oil (API ser vice SF , SG , SH,

or SJ)

Crankcase Capacity: 64 ounces (1.9 liter) with the

filter .

Viscosity: R efer to the table belo w

Figure 31

Checking the Engine Oil Level

1. P ark the mac hine on a lev el surface .

2. Diseng ag e the PTO , tur n the ignition k ey to

off , and remo v e the k ey .

28

Loading...

Loading...