shar pen the blades; refer to Shar pening the

Blades .

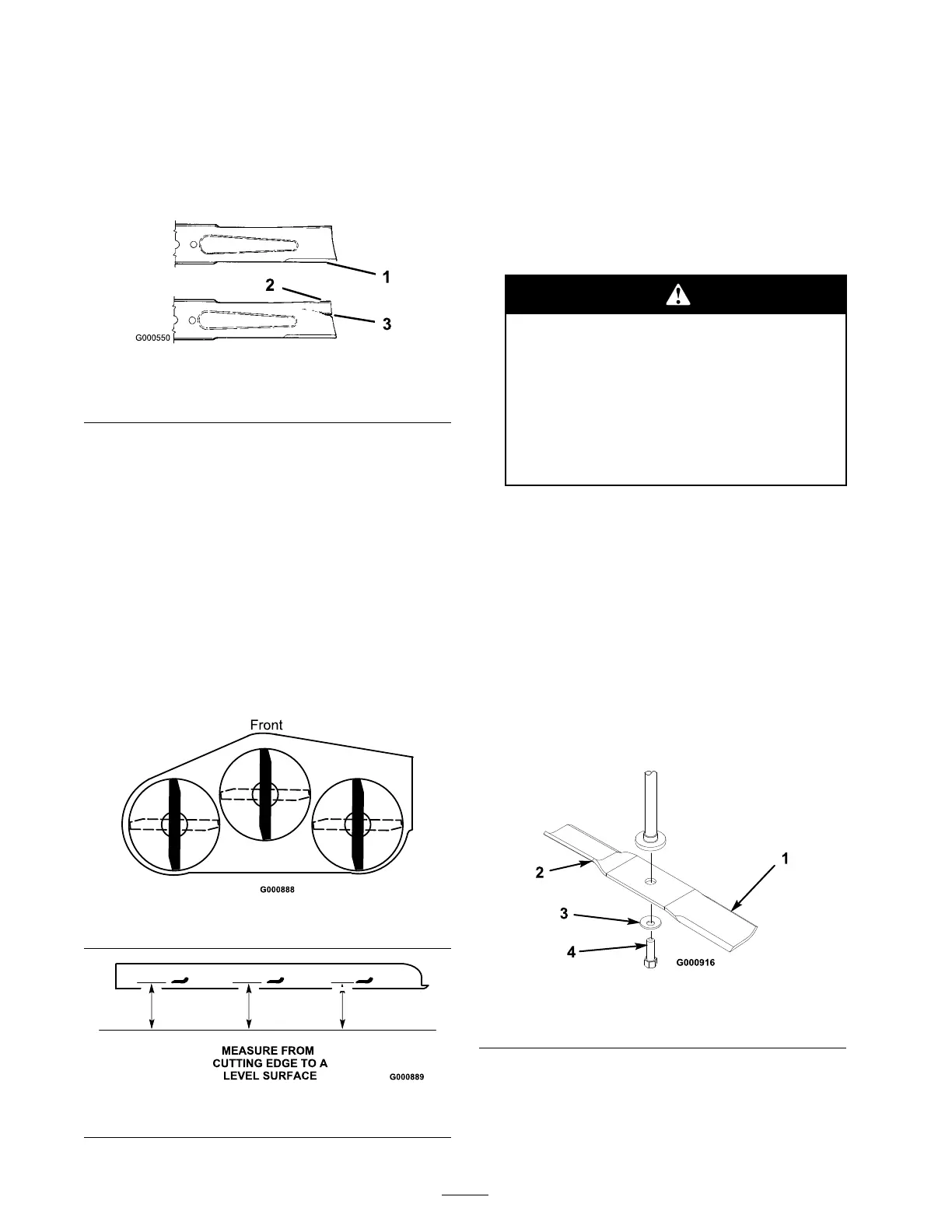

2. Inspect the blades , especially the cur v ed area

( Figure 35 ). If y ou notice any damag e , w ear , or

a slot for ming in this area (item 3 in Figure 35 ),

immediately install a new blade .

Figure 35

1. Cutting edge 3. Wear/slot forming

2. Curved area

Checking for Bent Blades

1. Diseng ag e the blade control switc h and mo v e

the control lev ers to the neutral loc k ed position

and apply the parking brak e .

2. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

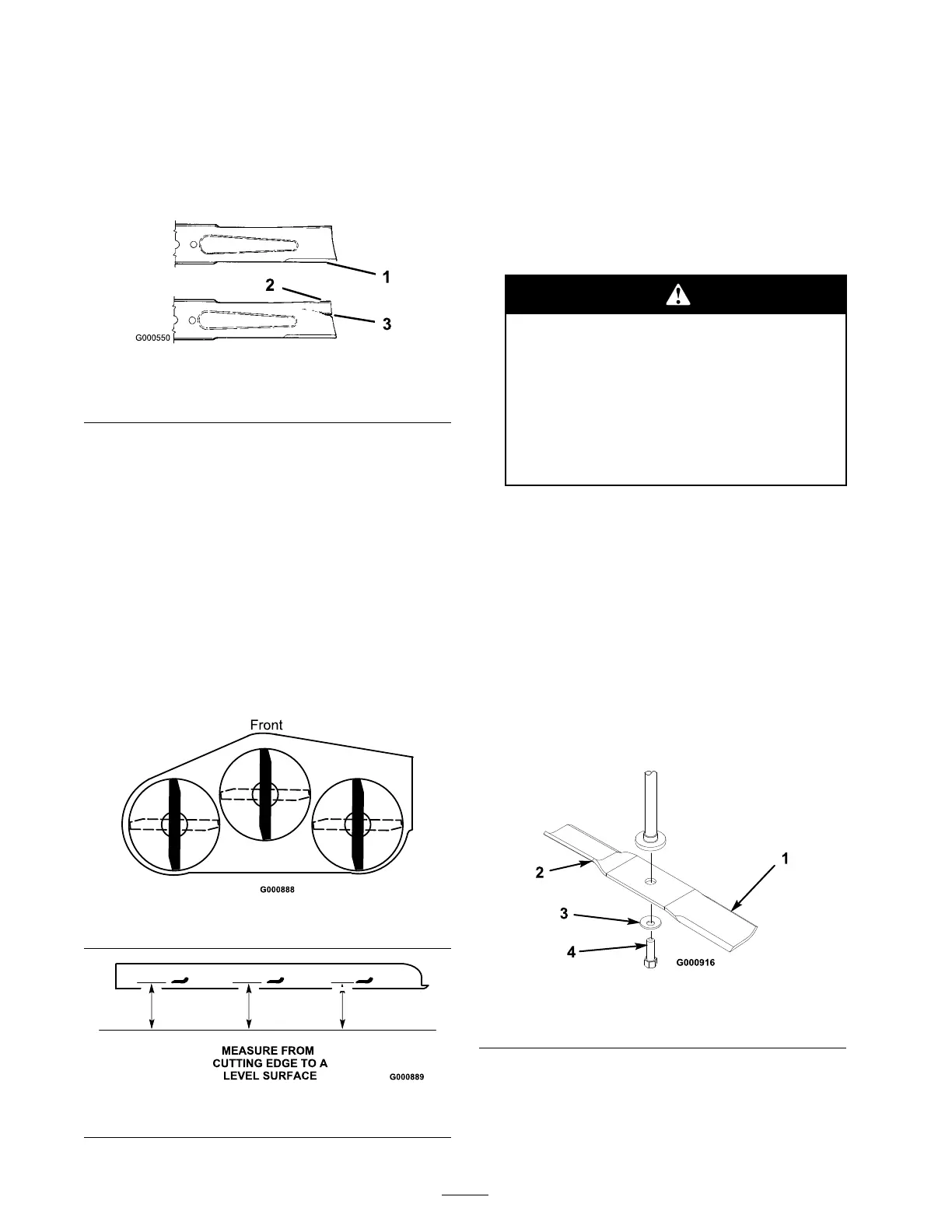

3. R otate the blades until the ends face forw ard

and bac kw ard ( Figure 36 ). Measure from a

lev el surface to the cutting edg e of the blades

( Figure 37 ). Note this dimension.

Figure 36

Figure 37

4. R otate the opposite ends of the blades forw ard.

5. Measure from a lev el surface to the cutting

edg e of the blades at the same position as

in ste p 3 abo v e . T he difference betw een the

dimensions obtained in ste ps 3 and 4 m ust not

ex ceed 1/8 inc h (3 mm). If this dimension

ex ceeds 1/8 inc h (3 mm), the blade is bent

and m ust be re placed; refer to R emo ving the

Blades and Installing the Blades .

A blade that is bent or dama ged could

br eak apar t and could seriousl y injur e or

kill y ou or bystander s.

• Al w ays r eplace bent or dama ged

blade with a new blade.

• Nev er file or cr eate shar p notches in

the edges or surf aces of blade.

Removing the Blades

T he blades m ust be re placed if a solid object is

hit, if the blade is out of balance , or the blade

is bent. T o ensure optim um perfor mance and

contin ued safety confor mance of the mac hine , use

g en uine T oro re placement blades . R e placement

blades made b y other man ufacturers ma y result in

non-confor mance with safety standards .

Hold the blade end using a rag or thic kly-padded

glo v e . R emo v e the blade bolt, cur v ed w asher , and

blade from the spindle shaft ( Figure 38 ).

Figure 38

1. Sail area of blade 3. Curved washer

2. Blade 4. Blade bolt

Sharpening the Blades

1. Use a file to shar pen the cutting edg e at both

ends of the blade ( Figure 39 ). Maintain the

30

Loading...

Loading...