EngineMaintenance

EngineSafety

Shutofftheenginebeforecheckingtheoiloradding

oiltothecrankcase.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Check

theaircleanerfordirty,looseor

damagedparts.

Every50hours—Servicetheair-cleanerpaper

element(moreoftenunderextremelydusty,

dirtyconditions).

Every100hours—Replacetheair-cleaner

paperelement(moreoftenunderextremely

dusty,dirtyconditions).

Thisengineisequippedwithareplaceable,

high-densitypaperair-cleanerelement.Checkthe

aircleanerdailyorbeforestartingtheengine.Check

forabuildupofdirtanddebrisaroundtheair-cleaner

system.Keepthisareaclean.Also,checkforlooseor

damagedcomponents.Replaceallbentordamaged

air-cleanercomponents.

Note:Operatingtheenginewithlooseordamaged

air-cleanercomponentscouldallowunlteredairinto

theengine,causingprematurewearandfailure.

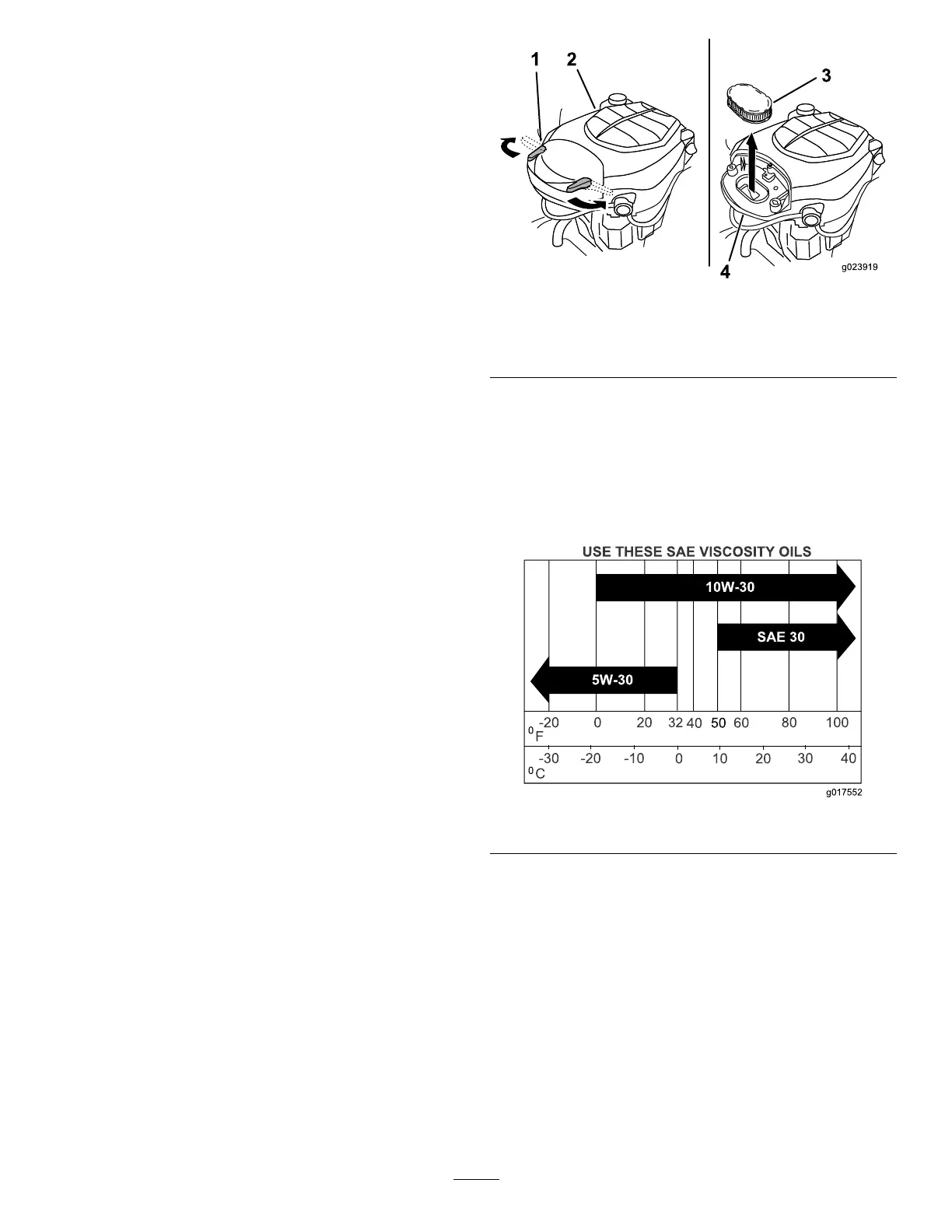

1.Rotatethelatchesoutward.

2.Removethecovertoaccesstheair-cleaner

element(Figure28).

3.Removetheelement,andgentlytaptheelement

todislodgedirt.

Note:Donotwashthepaperelementoruse

pressurizedair,asthiswilldamagetheelement.

Note:Replaceadirty,bent,ordamaged

element.Handlethenewelementcarefully;

donotuseifthesealingsurfacesarebentor

damaged.

4.Cleantheair-cleanerbaseasrequiredand

checkthecondition.

5.Installthepaperelementontotheair-cleaner

base.

6.Installthecoverandsecureitwiththelatches

(Figure28).

g023919

Figure28

1.Air-cleanerlatch3.Paperelement

2.Engine4.Air-cleanerbase

ServicingtheEngineOil

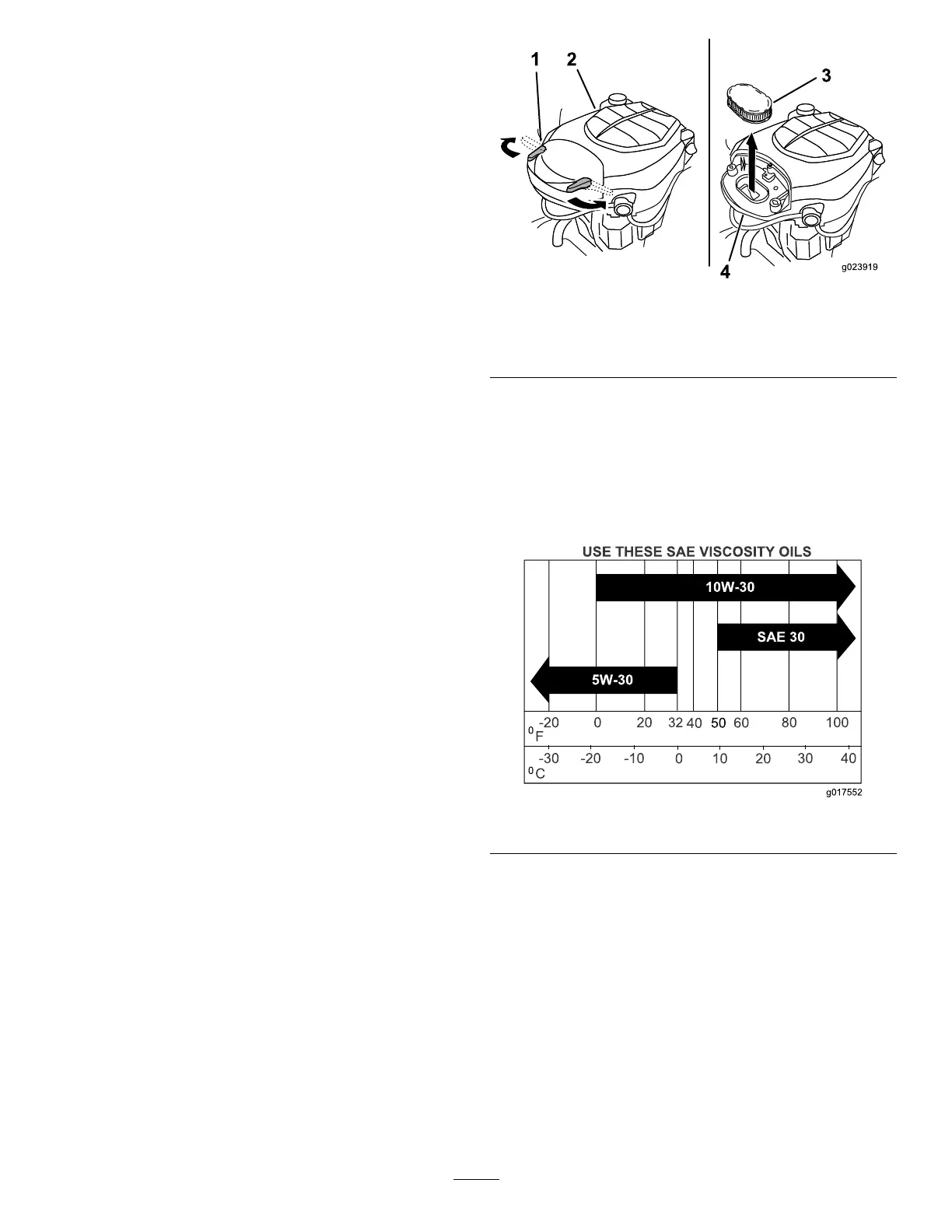

OilType:Detergentoil(APIserviceSJorhigher)

CrankcaseCapacity:1.9L(64oz)withtheoillter

Viscosity:Seethetablebelow.

g017552

Figure29

28

Loading...

Loading...