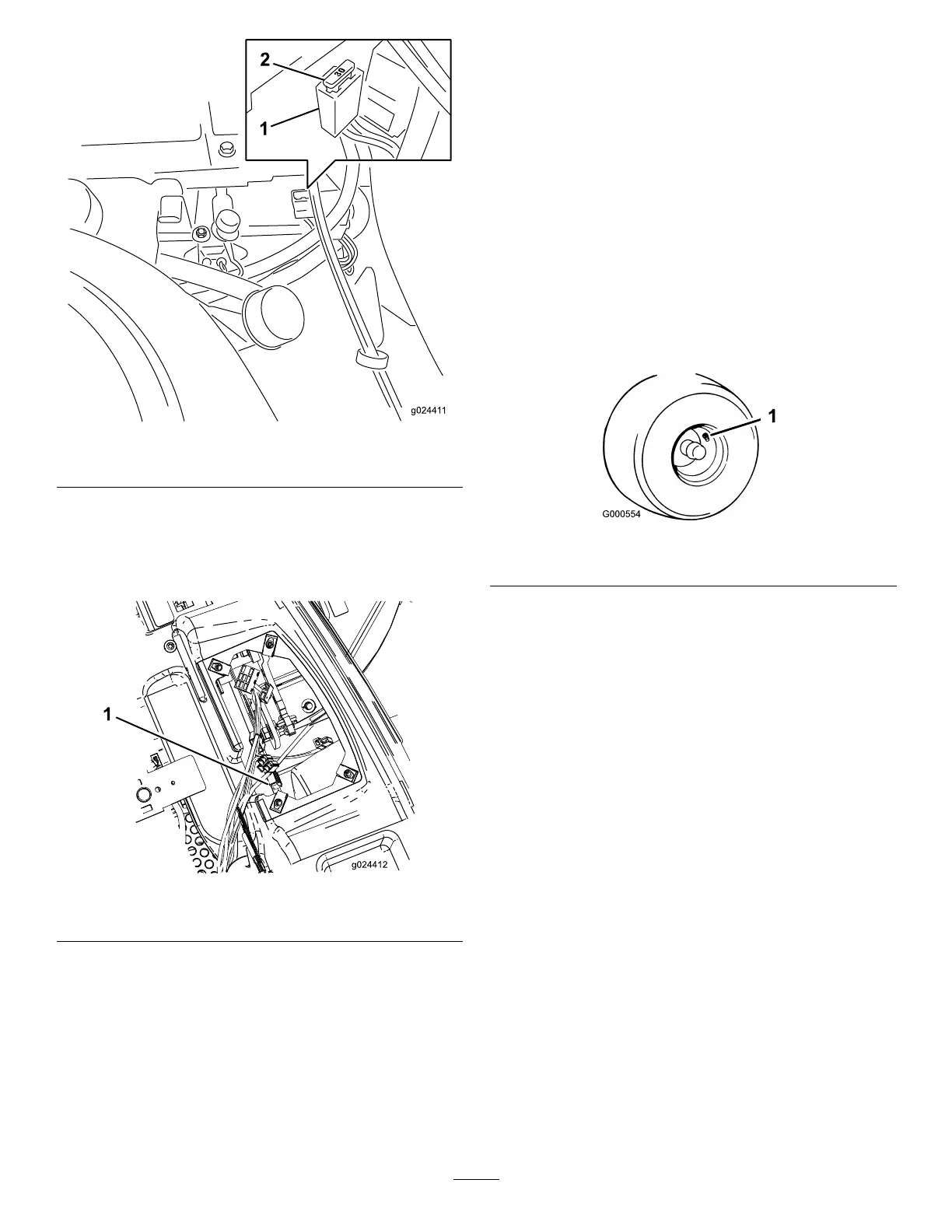

Figure47

1.Fuseblock2.Main—30A

Important:Ensurethatthenewfusesarethe

sametypeandamperageasthefusesremoved.

2.Toreplacetheenginefuse,removetheconsolefrom

theplasticfender.

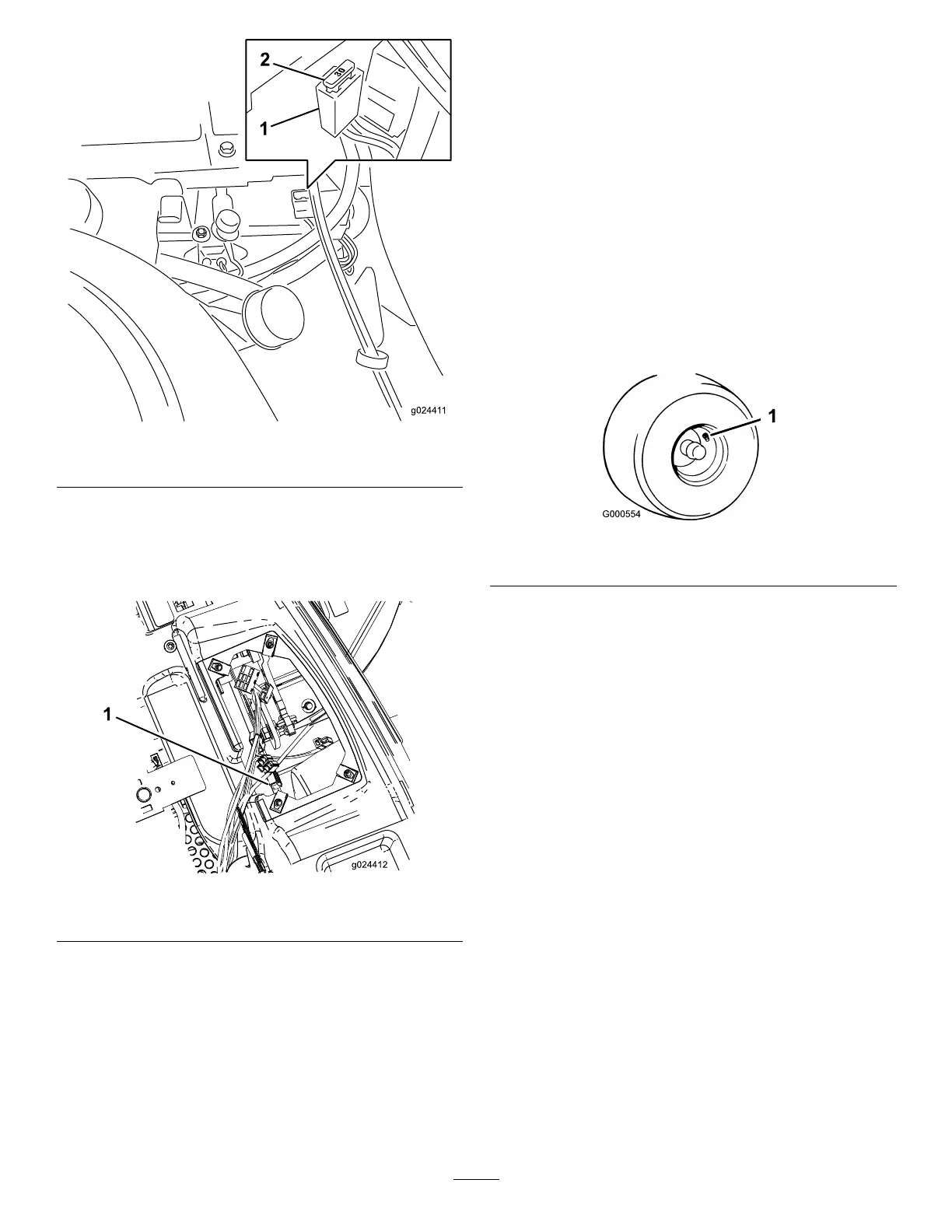

Figure48

1.Enginefuse—25A

3.Grasptheenginefuseandpullitstraightandaway

fromthefuseblock(Figure48).

4.Alignanewfusewiththeslotinthefuseblock(Figure

47).

5.Pushthefuseintothefuseblockuntilthefuseisseated

(Figure47).

DriveSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.Check

thepressureatthevalvestem(Figure49).Checkthetires

whentheyarecoldtogetthemostaccuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrivewheeltiresto90kPa(13psi).

Figure49

1.Valvestem

37

Loading...

Loading...