ControlsSystem

Maintenance

AdjustingtheControl-Handle

Position

Thereare2heightpositionsforthecontrollevers—highand

low .Removetheboltstoadjusttheheight.

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

andsettheparkingbrake.

2.Shutofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

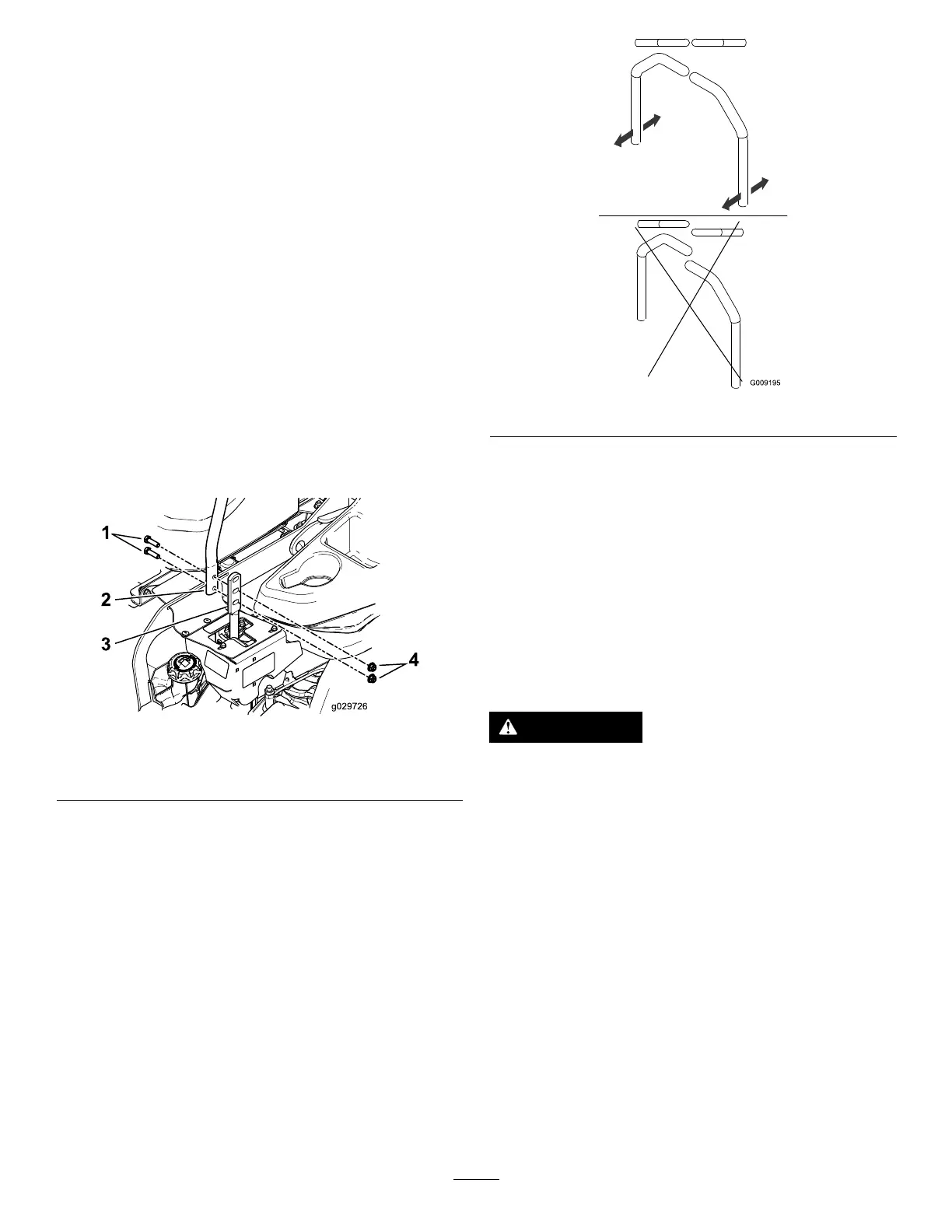

3.Loosentheboltsandangenutsinstalledinthelevers

(Figure83).

4.Aligntheleversinthefront-to-rearpositionbybringing

theleverstogethertotheNEUTRALposition,slidethem

untiltheyarealigned,andtightenthebolts(Figure83).

Figure83

1.Bolt

3.Controllever

2.Handle4.Nut

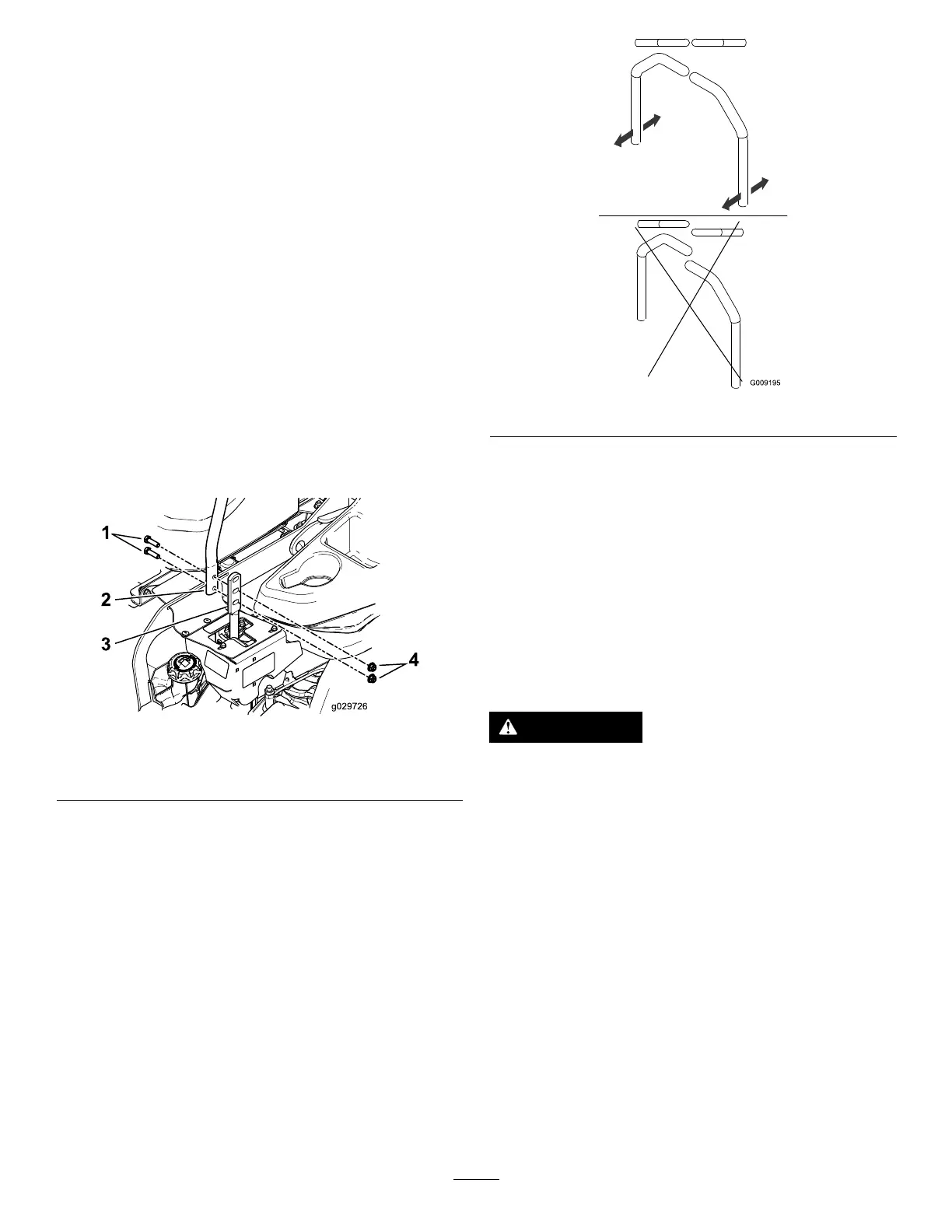

Figure84

5.Iftheendsofthelevershitagainsteachother,refer

toAdjustingtheMotion-ControlNeutral-LockPivot

(page58).

AdjustingtheMotion-Control

Linkage

Thepump-controllinkagesarelocatedoneithersideofthe

fueltank,belowtheseat.Rotatethepumplinkagewitha1/2

inchwrenchforne-tuningadjustmentssothatthemachine

doesnotmoveinneutral.Makeanyadjustmentsforneutral

positioningonly.

WARNING

Theenginemustberunningandthedrivewheels

mustbeturning,sothemotion-controladjustment

canbeperformed.Contactwithmovingpartsor

hotsurfacesmaycausepersonalinjury.

Keepyourngers,hands,andclothingclearof

rotatingcomponentsandhotsurfaces.

1.Priortostartingtheengine,pushthedeck-liftpedal,

removetheheight-of-cutpin,andlowerthedeckto

theground.

2.Raisetherearofmachineandsupportitwithjack

stands(orequivalentsupport)justhighenoughto

allowthedrivewheelstoturnfreely.

3.Removetheelectricalconnectionfromtheseatsafety

switch,locatedunderthebottomcushionoftheseat.

Note:Theswitchisapartoftheseatassembly.

4.Temporarilyinstallajumperwireacrosstheterminals

intheconnectorofthemainwireharness.

56

Loading...

Loading...