Maintenance Service

Interval

Maintenance Procedure

Every 300 hours

• Check and adjust the valve clearance. Contact an Authorized Service Dealer .

Before storage

• Charge the battery and disconnect the battery cables.

• Perform all maintenance procedures listed above before storage.

• Paint any chipped surfaces.

Important: Refer to your engine owner's manual for additional maintenance procedures.

CAUTION

If you leave the key in the switch, someone could accidently start the engine and seriously

injure you or other bystanders.

Shut off the engine and remove the key from the switch before you perform any maintenance.

Pre-Maintenance

Procedures

Raising the Machine

Use jackstands to support the machine when you

raise it.

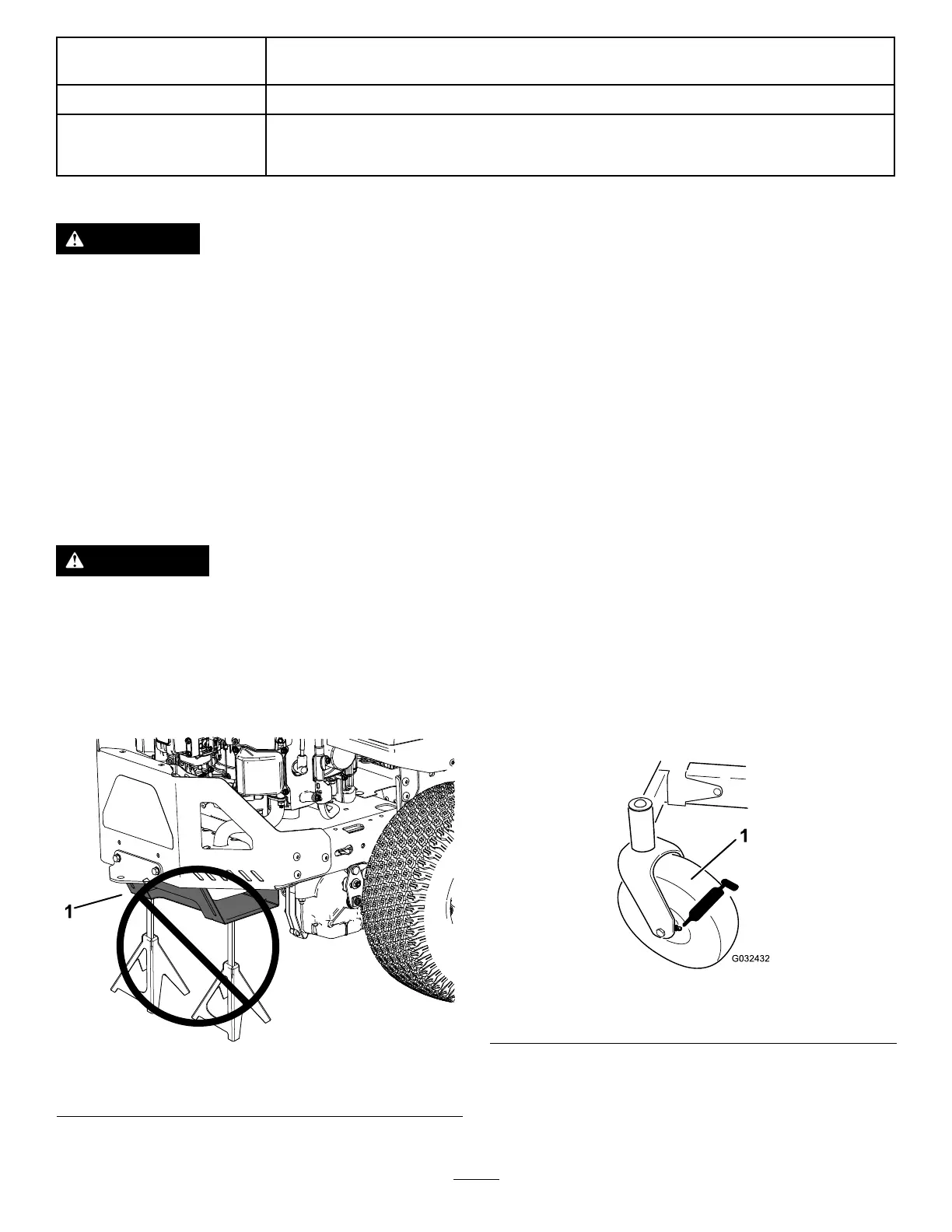

W ARNING

Supporting the machine on the lower mufer

shield ( Figure 32 ) may damage the shield and

cause the machine to fall, injuring you or

bystanders.

Do not use the lower mufer shield to lift or

support the machine.

g299647

Figure 32

1. Lower muf er shield

Lubrication

Greasing the Bearings

Service Interval : Every 25 hours —Grease the caster

wheel bearings (more often in sandy

soil conditions).

Grease T ype: No. 2 lithium grease

1. Park the machine on a level surface, disengage

the blade-control switch, and move the

motion-control levers outward to the P ARK

position.

2. Shut of f the engine, remove the key , and wait

for all moving parts to stop before leaving the

operating position.

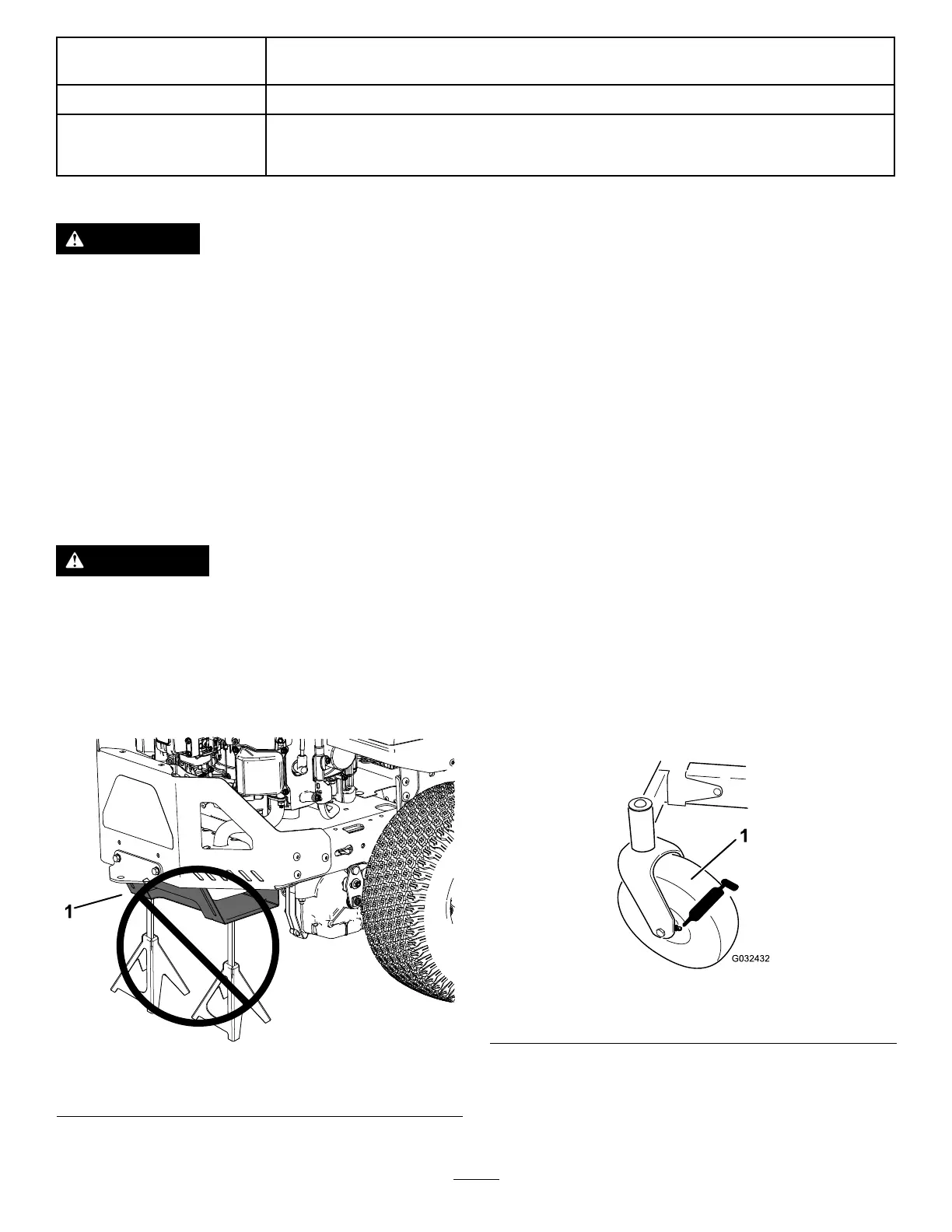

3. Clean the grease ttings ( Figure 33 ) with a rag.

Note: Scrape any paint of f the front of the

tting(s).

g032432

Figure 33

1. Front caster tire

4. Connect a grease gun to each tting ( Figure 33 ).

5. Pump grease into the ttings until grease begins

to ooze out of the bearings.

6. Wipe up any excess grease.

30

Loading...

Loading...