3

InstallingtheRollOver

ProtectionSystem(ROPS)

Partsneededforthisprocedure:

1Rollbar

2Rollbarsupport

4Pivotbracket

4Flatspacer

2Pivotpinwithhairpinandlanyard

2

Reinforcingbracket

4Largewasher

2

Bolt(1/2x4–1/2inches)

8

Bolt(1/2x3–1/2inches)

2

Cylindricalspacer

4

Flatwasher(1/2inch)

8

Flangelocknut(1/2inch)

2

Hexlocknut(1/2inch)

2

Flangelocknut(5/16inch,maybepre-installed)

2

Conicalrubberbumper(maybepre-installed)

2

Smallrubberbumper(maybepre-installed)

2

Bolt(5/16x3–3/4inch)

2

Flatwasher(5/16inch)

2

Flangelocknut(5/16inch)

InstallingtheRollbarSupports

Completethefollowingstepsforbothleftandright

rollbarsupports.

1.Locatethefactoryinstalledbraceattachedtothe

framebetweentheengineandtherearwheel(see

Figure3andFigure4).

Note:Ifpreferred,therearwheelsmayberemoved

foreasieraccesstothebrace.

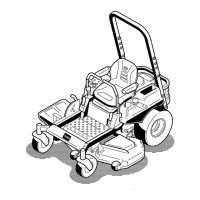

Figure3

Locationofthebraces

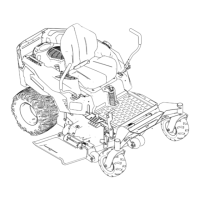

Figure4

1.Bolt(1/2x3–1/2inches)

(2)

9.Hexlocknut(1/2inch)(2)

2.Largewasher(4)10.Flangelocknut(1/2inch)

(2)

3.Rollbarsupport

11.Reinforcingbracket(2)

4.Cutoutfacestherear12.Bolt(1/2x4–1/2inch)(2)

5.Brace,existing

13.Bolt(5/16x3–3/4inch)(2)

6.Bolt(1/2x1–1/4inch)and

locknut(1/2inch),existing

14.Flatwasher(5/16inch)(2)

7.Seatbeltassembly,

existing

15.Flangelocknut(5/16inch)

(2)

8.Smallrubberbumper(2)

16.Engineguard

2.Loosenthelocknutthatsecuresthebracetothe

frame.Stopwhenthebraceswingsfreely(Figure4).

3.Attachtherollbarsupporttotheframeandthebrace

totherollbarsupportasshowninFigure4.Leave

theboltslooseenoughthatthepartsarefreetoshift

around.

Note:Ensurethatthecutoutatthetopofthe

supporttubefacestherearofthemachine.

Note:Notetheorientationofthereinforcing

bracket.

4.Attachtherollbarsupporttotheengineguardas

showninFigure4.

AttachingthePivotBrackets

Assemblethepivotbracketstotherollbarasshownin

Figure5.Leavetheboltslooseenoughthatthepartsare

freetoshiftaround.

Note:Ensurethatthelocknutsareontheinsideofthe

supporttube.

4

Loading...

Loading...