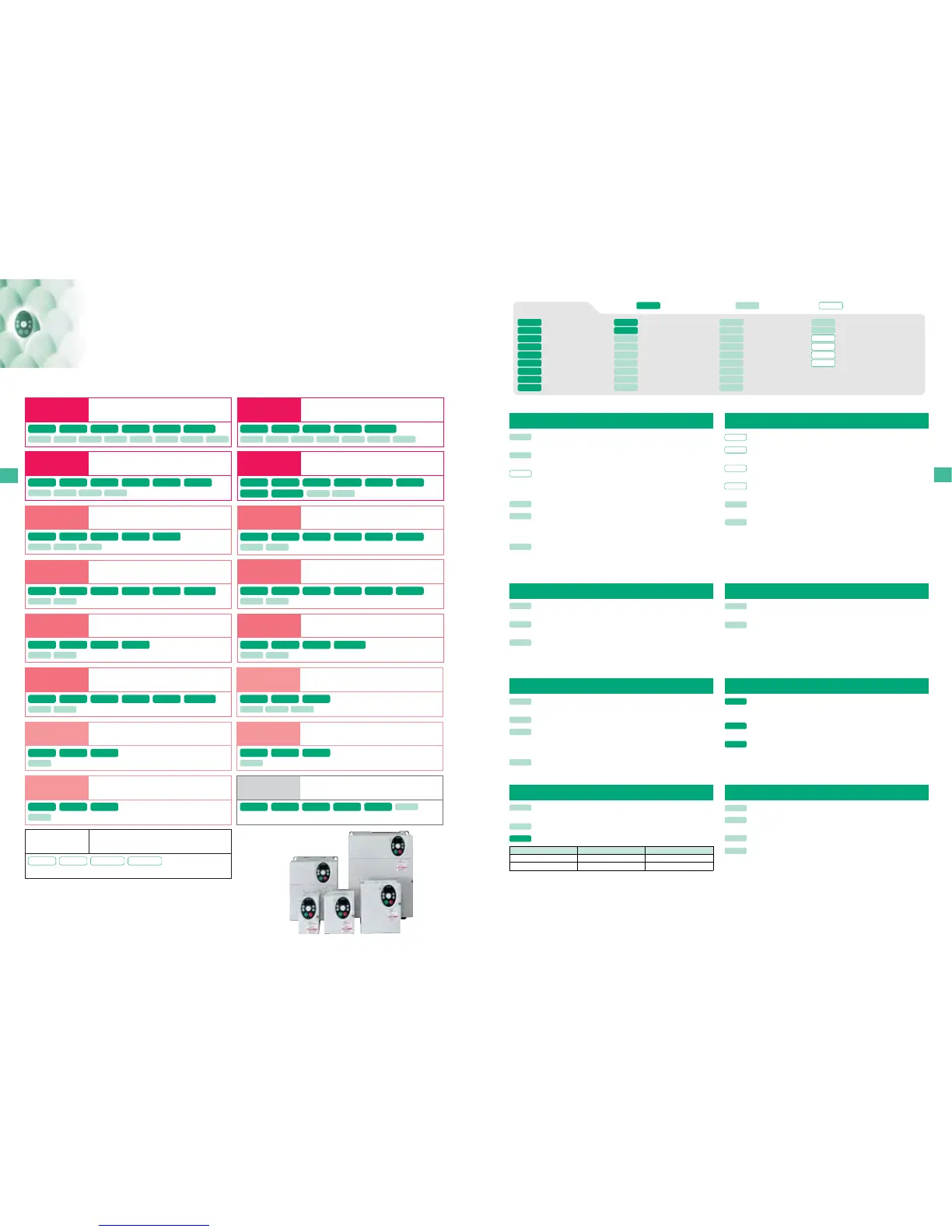

Applicable specification by each segment

3

Fan & Pumps

Air-conditioning systems, various fans, blowers, pumps,

plumbing/sewerage systems, clean rooms, driers

Noise filter

Energy savings

Deceleration

Restart Non-stop One-touch PID control

Ground capacitor

General

General related items, common items, other

History Log details

28 monitors Storage

Applicable specification by each segment

The VF-S11 is provided with a wide range of useful functions

for machinery and facilities in various industrial sectors and applications.

Replacement alarm

Life 10 years

60C˚

Capacity range

Standards

Conveyance

machinery

Conveyors, automatic vertical storage units, hoists, lifts,

dumbwaiters

High torque

Braking resistance

8 inputs

2 output functions

Step width Free unit

Speed control

Standards

Compact

Side-by-side

Amusement

machinery

Batting machines, pinball feeders, game machines

High torque

Braking resistance

Ground capacitor

Noise filter

Compact

Side-by-side

60C˚

Totally enclosed

Commercial ironing boards, car washing machines,

raw garbage disposal, dust collectors

Lumber machinery, woodworking machinery,

plywood making machinery

High torque

Braking resistance

Ground capacitor

Noise filter

Compact

Side-by-side

Communications

Capacity range

Side-by-side

60C˚

Totally enclosed

Printing

machinery

Platemakers, binding machines, printing presses

High torque

Step width Free unit

Compact

Side-by-side

Capacity range

Agricultural

machinery

Rice and wheat milling machines,

fruit selection machines

High torque

Braking resistance

Ground capacitor

Noise filter

Compact

Machine

tools

Lathes, drilling machines, hobbing machines,

grinding machines, boring machines

High torque

500 Hz

Compact

Capacity range

Chemical

machinery

Mixers, extruding machines, centrifugal separators,

painting machines, pulverizers

High torque

Restart

Compact

Capacity range

Textile

machinery

Weaving machines, knitting machines,

dyeing/finishing machines, sewing machine

Compact

500 Hz

Detachable

Communications

Food processing

machinery

Bread, confectionery, tea, and noodle making machines,

rice, wheat and powder milling machines, mixers, slivers,

and fruit selection machines

High torque

Totally enclosed box type

Deceleration

Braking resistance

8 inputs

Noise filter

Compact

Side-by-side

60C˚

Capacity range

Commercial

facility

equipment

Semiconductor

production

equipment

Metal

processing

machinery

Stairway elevators, nursing beds, Jacuzzis, health

equipment (treadmills), medical equipment

(X-ray machines)

High torque

Braking resistance

Free unit

Ground capacitor

Semiconductor production equipment,

LCD production equipment, electronic component

production and assembly machinery

High torque

Speed control

Ground capacitor

Noise filter

Compact

Side-by-side

Life 10 years

Capacity range

Noise filter

Compact

Side-by-side

Detachable

Control panels, special control panels

Panel

manufacturer

Compact

Side-by-side

60C˚

Detachable

Capacity range

Ground capacitor

Totally enclosed

Capacity range

Totally enclosed

Totally enclosed

Packaging

machinery

Trimming machines, packing machines,

wrapping machines, band tighteners

High torque

Deceleration

Braking resistance

Noise filter

Capacity range

Compact

Side-by-side

Detachable

Communications

High torque

500 Hz

Power voltage

Non-stop Pulse train

Various rolling and shearing machinery,

mechanical pressing, winding and take-up machines

High torque

Braking resistance

Compact

Capacity range

Compact

Capacity range

Woodworking

machinery

Totally enclosed

Medical

equipment

Semiconductor

production

equipment

Metal

processing

machinery

4

Applicable specification by each segment

High torque (1 Hz - 200% or more)

Built-in noise filter

Small-sized, compact

Side-by-side installation

Expected replacement period alarm for spare parts

Main circuit capacitor designed to have a life of 10 years

Possible installed in an ambient temperature 60°C

Detachable terminal block

Built-in communications options

Wide capacity range up to 15 kW.

Totally enclosed box type (IP54, IP55 compatible)

Dynamic energy saving function

Dynamic deceleration time reduction

Instantaneous power interruption restart (frequency scan system)

Instantaneous power interruption non-stop control function

One-touch fan replacement

PID control with wait time

Built-in braking resistor drive circuit

:Described pages 1 and 2.

:Described page 4. :Functions enabled on all models

Dynamic automatic energy savings: A new function exclusively for fans

and pumps in addition to the conventional energy savings mode. With this

function, you can expect considerable energy savings.

Dynamic deceleration time reduction control: Conventional deceleration time

reduction control has been further modified. With this function, you can

expect

a certain

amount of reduction in deceleration time even without the aid of a braking resistor.

Energy saving effect monitor: Besides monitoring of input/output power

(momentary values), the effect of energy savings can be easily checked as the

input/output watt-hour power (electric energy) can be monitored.

Instantaneous power interruption restart function: The inverter can be restarted

smoothly without any shock as it employs a frequency scan system.

Instantaneous power interruption restart function: The inverter can be

restarted smoothly without any shock as it employs a frequency scan system.

Instantaneous power interruption non-stop control: This function uses

the regenerative energy from the motor to continue inverter operation when a

power interruption occurs during operation. In the same way, regenerative

energy can be used to decelerate the motor to a stop without the inverter

running free and then stopping.

PID control: Conventional PID control functions have been enhanced for

even easier use. New functions are a wait time for applying a time period in

which PID control is disabled at startup and a function for resetting integrated

amounts.

Dynamic Automatic Energy Savings

Energy savings

Deceleration

28 monitors

Restart

Non-stop

PID control

Extensive monitor menus: 28 monitor values including load current and

torque current can be viewed in real time.

Monitor at trip: 28 momentary monitor values for when a trip occurs can

be viewed. Ten monitor values are stored in memory for the last four inverter

operations, which is effective in pin-pointing the cause of a trip.

Storage of user parameter settings: All parameter settings made by the

user can be stored in memory. Stored parameters can be immediately called

even they have been changed.

History function: This function is for displaying the latest five changes

made to parameter settings. This is displayed in the top menu (AUH), which is

handy when parameters are frequently changed or repeatedly adjusted.

Free unit display: Bias can also be set in addition to the multiplication

factor in the free unit display. This display shows speed of rotation, line speed

and other units in addition to frequency.

Variable step width setting: The change increment of the frequency

when an arrow key on the panel is pressed can be set as desired. For example,

this is convenient when you want to change the frequency in 10 Hz increments

each time that a key is pressed.

Full Lineup of Monitor and Display Functions

8 contact input terminals: Analog input terminals can be selected as

contact inputs. This means that up to eight contact inputs can be set to support

more complex settings.

76 menus: A variety of operation specifications are supported as

functions selected from 66 menus can be individually assigned to contact input

terminals.

Use of external power supply possible: A PLC terminal is provided for

input of an external +24 V power supply. This is convenient when the inverter is

connected to a programmable controller. A +24 V power supply is also

integrated into the inverter which can also be used for contact input.

Various Input Terminals

8 inputs

8 inputs

8 inputs

3 contact output terminals: Various outputs are provided on three

terminals, relay contact (1c) output, relay contact (1a) output, and open collector

output.

Pulse train output: Open collector output is insulated from other circuits

so that it can also be used as pulse train output.

58 menus: Functions selected from 58 menus can be individually

assigned to contact output terminals. Moreover, two menus can be

simultaneously assigned to a single terminal. A hold function for holding the

state of an input once it turns ON is also provided. This enables inverter

compatibility with various operation specifications.

Analog output terminal: Any of 0 to 10 V, 0 to 1 mA and 4 to 20 mA can

be selected. Also, data can be selected from 20 menus.

Various Output Terminals

2 output functions

Pulse train

2 output functions

2 output functions

Compatibility with main standards: All models are compatible with the

World's Main Standards (EC Directive (CE marking), UL, and CSA. Some of C-

tick complied models are also available.

Sink/source logic switching: Sink or source (i.e. positive - negative) on

input terminals can be easily switched by the bit switch on the circuit board.

Built-in noise filter: A noise filter is built into all models.

*1. A noise reduction filter (EU-compatible) compatible with the EMC Directive is available. See page 20.

Compatibility with World’s Main Standards

Standards

Sink/source

Noise filter

28 monitors

Log details

Storage

History

Free unit

Step width

One-touch fan replacement: The cooling fan, one of the service parts,

can be easily removed for replacement. The fan, of course, is designed to last a

long time as it has a temperature-based ON/OFF control function.

Ground capacitor disconnection switch: Even when current leakage is a

problem, it is possible to reduce current leakage easily with a ground condenser

cutoff switch. (Only on single-phase 240 V models and 3-phase 500 V models)

Safe Maintenance

One-touch

Ground capacitor

Wide power supply voltage range: 200 to 240 V range on 200 V class

models, and 380 to 500 V range on 400 V class models are supported.

Speed control accuracy: Speed control accuracy is improved by high

startup torque and current vector calculation control, a TOSHIBA proprietary

control system.

Output frequency: The VF-S11 can be used in a wide range of

applications as its maximum output frequency is 500 Hz.

Built-in braking resistor drive circuit: A drive circuit for an external

braking resistor is integrated into all models to enable large regenerative energy

loads to be stopped in a short time.

Other Features

Built-in communications option board: The detachable terminal block

board can be detached and swapped with various internal option boards.

Communications option boards including RS-485, DeviceNET and LonWorks

are available.

Communications protocol: TOSHIBA inverter protocol and Modbus-RTU

protocol are supported. The inverter can also be connected directly by

communications to touch panels made by Digital Electronics Corporation.

Block communications: Block read/write functions have been added on

as communications methods to simplify high-speed transmission of instructions

and monitoring. Inverter-to-inverter communications is also supported, which

enables master/slave control on just inverters without the aid of a host

controller.

Extensive Communication Functions

Detachable

Communications

Communications

Model Built-in Filter European EMC Directive

Single-phase models, 500 V models

3-phase240Vmodels

High-attenuation EMI filter

Standardfilter

Compatible on standard products

Optionally*compatible

High torque

Noise filter

Compact

Side-by-side

Replacement alarm

Life 10 years

60°C

Detachable

Communications

Capacity range

Totally enclosed

Energy savings

Deceleration

Restart

Non-stop

One-touch

PID control

Braking resistance

8 inputs

2 output functions

Step width

Free unit

500 Hz

Pulse train

Speed control

Power voltage

Ground capacitor

Standards

Sink/source

History

Log details

28 monitors

Storage

Compatible with main standards (CE, UL, CSA)

Sink/source logic switching

History function

Detailed information of past tripping

28 monitor functions (power, watt-hour power)

Storage of user parameter settings

8 logic inputs

2 output terminal functions are assigned.

Variable step width setting

Free unit multiplication factor, bias setting

Max. frequency 500 Hz

Pulse train output

Speed control accuracy

Wide power supply voltage range (240 V, 500 V)

Ground capacitor disconnection switch

Explanation of symbols

Power voltage

Speed control

500 Hz

Braking resistance

Loading...

Loading...