5 6

Standard specifications

■Common specification

Sinusoidal PWM control

Digital setting: within ±0.01% of the max. frequency (-10 to +60°C)

Analog setting: within ±0.5% of the max. frequency (25°C ±10°C)

Potentiometer on the front panel, external frequency potentiometer (connectable to a potentiometer with a rated impedance

of 1 - 10kΩ), 0 - 10Vdc (input impedance: VIA/VIB=30kΩ), 4 - 20mAdc (Input impedance: 250Ω).

The characteristic can be set arbitrarily by two-point setting. Possible to set individually for three functions: analog input (VIA and VIB) and communication command.

Three frequencies can be set. Setting of the jump frequency and the range.

Upper-limit frequency: 0 to maximum frequency, lower-limit frequency: 0 to upper-limit frequency

Adjustable within a range of 2.0 to 16.0Hz (default: 12kHz).

Setting of proportional gain, integral gain, differential gain and control wait time. Checking whether the amount of processing amount and the amount of feedback agree.

The RUN and STOP keys on the operation panel are used to start and stop operation. The switching between forward run and

reverse run can be done from one of the three control units: operation panel, terminal board and external control unit.

In the event of a momentary power failure, the inverter reads the rotational speed of the coasting motor and outputs a frequency appropriate

to the rotational speed in order to restart the motor smoothly. This function can also be used when switching to commercial power.

Switching between standard motor and constant-torque VF motor, switching between motors 1 and 2, setting of overload

trip time, adjustment of stall prevention levels 1 and 2, selection of overload stall

Stores data on the past four trips: number of trips that occurred in succession, operation frequency, direction of rotation, load current, input

voltage, output voltage, information on input terminals, information on output terminals, and cumulative operation time when each trip occurred.

Lamps indicating the inverter status by lighting, such as RUN lamp, MON lamp, PRG lamp, % lamp, Hz lamp, frequency

setting potentiometer lamp, UP/DOWN key lamp and RUN key lamp. The charge lamp indicates that the main circuit

capacitors are electrically charged.

Function of resetting by closing contact 1a or by turning off power or the operation panel. This function is also used to save and clear trip records.

Stall prevention, overvoltage, overload, under-voltage, setting error, retry in process, upper/lower limits

Indoor, altitude: 1000m (Max.), not exposed to direct sunlight, corrosive gas, explosive gas / vibration (less than 5.9m/s

2

) (10 to 55Hz)

-10 to +60°C

Note 9,10)

-25 to +70°C

20 to 93% (free from condensation and vapor).

Stall prevention, current limitation, over-current, output short circuit, over-voltage, over-voltage limitation, undervoltage, ground fault, power supply phase

failure, output phase failure, overload protection by electronic thermal function, armature over-current at start-up, load side over-current at start-up, over-

torque, undercurrent, overheating, cumulative operation time, life alarm, emergency stop, braking resistor over-current/overload, various pre-alarms

Over-current, overvoltage, overheating, short-circuit in load, ground fault, overload on inverter, over-current through arm at start-up, over-

current through load at start-up, CPU fault, EEPROM fault, RAM fault, ROM fault, communication error. (Selectable: Over-current

through braking resistor/overload, emergency stop, under-voltage, low voltage, over-torque, motor overload, output open-phase)

Analog output (1mAdc full-scale DC ammeter or 7.5Vdc full-scale DC voltmeter/rectifier type AC voltmeter, 4 to 20mA/0

to 20mA output)

Operation frequency, operation frequency command, forward/reverse run, output current, voltage in DC section, output voltage, torque,

torque current, load factor of inverter, integral load factor of PBR, input power, output power, information on input terminals, information on

output terminals, version of CPU1, version of CPU2, version of memory, PID feedback amount, frequency command (after PID), integral

input power, integral output power, rated current, causes of past trips 1 through 4, information on life alarm, cumulative operation time

Frequency: inverter output frequency.

Alarm: stall alarm “C”, overvoltage alarm “P”, overload alarm “L”, overheat alarm “H”.

Status: inverter status (frequency, cause of activation of protective function, input/output voltage, output current, etc.) and parameter settings.

Free-unit display: arbitrary unit (e.g. rotating speed) corresponding to output frequency.

Possible to select from 76 functions, such as forward/reverse run signal input, jog run signal input, operation base signal

input and reset signal input, to assign to 8 input terminals. Logic selectable between sink and source.

Possible to select from 58 functions, such as upper/lower limit frequency signal output, low speed detection signal output, specified speed

reach signal output and failure signal output, to assign to FL relay output, open collector output and RY output terminals.

Capable of restarting automatically after a check of the main circuit elements in case the protective function is activated. 10 times (Max.) (selectable with a parameter)

Possible to write-protect parameters and to prohibit the change of panel frequency settings and the use of operation panel for operation, emergency stop or resetting.

Possible to keep the motor running using its regenerative energy in case of a momentary power failure.

When two or more inverters are used to operate a single load, this function prevents load from concentrating on one inverter due to unbalance.

The sum of two analog signals (VIA/VIB) can be used as a frequency command value.

1c-contact output: (250Vac-0.5A-cos

φ

=

0.4)

Braking start-up frequency: 0 to maximum frequency, braking rate: 0 to 100%, braking time: 0 to 20 seconds, emergency

DC braking, motor shaft fixing control

Selectable from among acceleration/deceleration times 1, 2 or 3 (0.0 to 3200 sec.). Automatic acceleration/deceleration function.

S-pattern 1 or 2, and S-pattern value adjustable. Forced rapid deceleration and dynamic rapid deceleration function.

Control and drive circuit is built in the inverter with the braking resistor outside (optional).

Jog mode, if selected, allows jog operation from the operation panel or the terminal board.

Base frequency + 15-speed operation possible by changing the combination of 4 contacts on the terminal board.

Adjustable within the range of 50 to 600V by correcting the supply voltage (not adjustable above the input voltage)

0.5 to 500.0Hz, default setting: 0.5 to 80Hz, maximum frequency: 30 to 500Hz

0.01Hz: operation panel setting, 0.1Hz: analog input (when the max. frequency is 100Hz).

V/f constant, variable torque, automatic torque boost, vector control, automatic energy-saving, dynamic automatic energy-

saving control. Auto-tuning. Base frequency (25 - 500Hz) adjusting to 1 or 2, torque boost (0 - 30%) adjusting to 1 or 2,

adjusting frequency at start (0.5 - 10Hz)

Principal control functionsOperation specificationsProtective functionDisplay function

Environments

Control system

Rated output voltage

Output frequency range

Minimum setting steps of frequency

Frequency accuracy

Voltage/frequency characteristics

Frequency setting signal

Terminal board base frequency

Frequency jump

Upper- and lower-limit frequencies

PWM carrier frequency

PID control

Acceleration/deceleration time

DC braking

Dynamic braking

Input terminal function

(programmable)

Output terminal functions

(programmable)

Forward/reverse run

Jog run

Preset speed operation

Retry operation

Various prohibition settings

Regenerative power ride-through control

Auto-restart operation

Drooping function

Override function

Failure detection signal

Protective function

Electronic thermal characteristic

Reset function

Alarms

Causes of failures

Monitoring function

Past trip monitoring function

Output for frequency meter

4-digit 7-segments LED

Indicator

Use environments

Ambient temperature

Storage temperature

Relative humidity

SpecificationItem

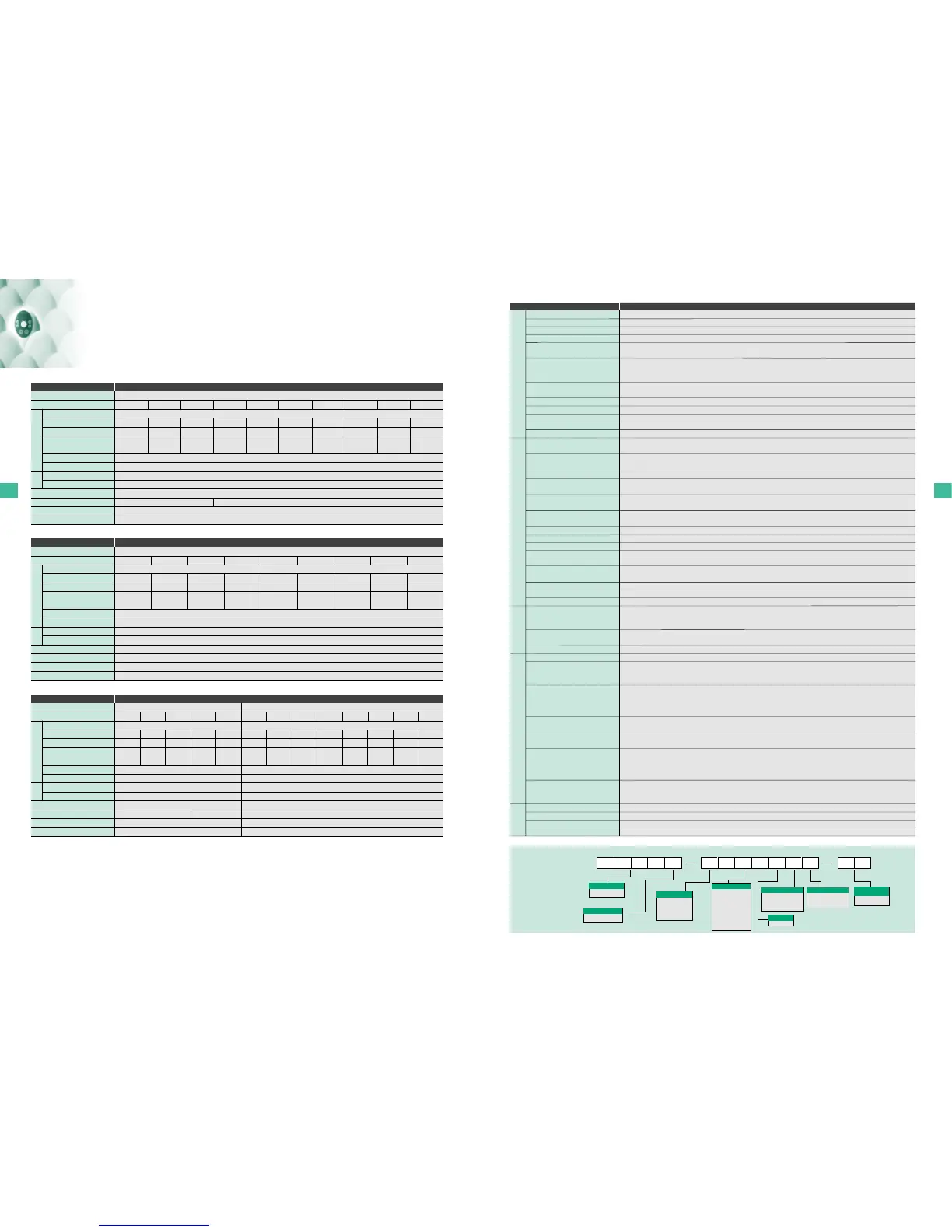

■3-phase 240V

■1-phase 240V ■3-phase 600V

Item Specification

3-phase 240V

VFS11

3-phase 200V to 240V

150%-60 seconds, 200%-0.5 second

Note 4)

3-phase 200V to 240V - 50/60Hz

Voltage + 10%, -15%

Note 5)

, frequency ±5%

IP20 Enclosed type (JEM1030)

Munsel 5Y-8/0.5

Self-cooling

Basic filter

Note 7)

Forced air-cooled

3.3

(3.3)

4.8

(4.4)

8.0

(7.9)

17.5

(16.4)

27.5

(25.0)

33

(33)

54

(49)

66

(60)

2004PM

1.3

2007PM

1.8

2015PM

3.0

2037PM

6.7

2055PM

10

2075PM

13

2110PM

21

2150PM

25

0.4

3.7

(3.3)

2005PM

1.4

0.55 0.75 1.5

11.0

(10.0)

2022PM

4.2

2.2 4.0 5.5 7.5 11 15

Input voltage class

Applicable motor (kW)

Protective method

Cooling method

Color

Built-in filter

Type

Form

Capacity (kVA)

Note 1)

Output voltage

Note 3)

Overload current rating

Voltage-frequency

Allowable fluctuation

Rated output current

(A)

Note 2)

Rating

Power

supply

Item

Note 1.

Note 2.

Note 3.

Note 4.

Note 5.

Note 6.

Note 7.

Note 8.

Note 9.

Note

10

.

Capacity is calculated at 220V for the 240V class, at 440V for the 500V class and at 575V for the 600V models.

Indicates rated output current setting when the PWM carrier frequency (parameter F300) is 4kHz or less.

When exceeding 4kHz, the rated output current setting is indicated in the parenthesis. When the input power voltage of the 500V class model exceeds 480V, it is necessary to further reduce the setting. The default

setting of the PWM carrier Frequency is 12kHz.

Maximum output voltage is the same as the input voltage.

May differ according to voltage and model.

±10% when the inverter is used continuously (load of 100%).

If you are using 600V model, be sure to connect an input reactor (ACL).

Built-in standard filter: Core and capacities With RFI noise filter option: Complies EN55011 Class A Group 1(Max.5m*) and Class B Group 1(Max.1m*)

* Length of motor connecting cable.

Built-in high-attenuation EMI filter: Complies EN55011 Class A Group 1(Max.5m*) With RFI noise filter option : Complies EN55011 Class B Group 1(Max.20m*) and Class A Group 1(Max.50m*)

* Length of motor connecting cable.

Above 40°C : Remove the protective seal from the top of the inverter. Above 50°C: Remove the seal from the top of the inverter and use the inverter with the rated output current reduced.

If inverters are installed side by side (with no sufficient space left between them) installation: Remove the seal from the top of each inverter.

When installing the inverter where the ambient temperature will rise above 40°C, remove the seal from the top of the inverter and use the inverter with the rated output current reduced.

■3-phase 500V

Item

Standard specifications

Input voltage class

Applicable motor (kW)

Protective method

Cooling method

Color

Built-in filter

Type

Form

Capacity (kVA)

Note 1)

Output voltage

Note 3)

Overload current rating

Voltage-frequency

Allowable fluctuation

Rated output current

(A)

Note 2)

Rating

Power

supply

Input voltage class

Applicable motor (kW)

Protective method

Cooling method

Color

Built-in filter

Type

Form

Capacity (kVA)

Note 1)

Output voltage

Note 3)

Overload current rating

Voltage-frequency

Allowable fluctuation

Rated output current

(A)

Note 2)

Rating

Power

supply

IP20 Enclosed type (JEM1030)

3-phase 500V

3-phase 380V to 500V

150%-60 seconds, 200% -0.5 second

Note 4)

3-phase 380V to 500V - 50/60Hz

Voltage + 10%, -15%

Note 5)

, frequency ±5%

0.75 1.5 2.2 4.0 5.5 7.5 11 15

4007PL

1.8

2.3

(2.1)

0.4

4004PL

1.1

1.5

(1.5)

4015PL

3.1

4.1

(3.7)

4022PL

4.2

5.5

(5.0)

4037PL

7.2

4055PL

11

4075PL

13

4110PL

21

4150PL

25

9.5

(8.6)

14.3

(13.0)

17.0

(17.0)

27.7

(25.0)

33

(30)

Forced air-cooled

Munsel 5Y-8/0.5

High-attenuation EMI filter

Note 8)

Specification

VFS11

1-phase 240V 3-phase 600V

Note 6)

VFS11S VFS11

3-phase 200V to 240V

1-phase 200V to 240V – 50/60Hz 3-phase 525V to 600V – 50/60Hz

3-phase 525V to 600V

0.2 0.4 0.75 1.5 2.2

2002PL

0.6

1.5

(1.5)

2004PL

1.3

3.3

(3.3)

2007PL

1.8

4.8

(4.4)

2015PL

3.0

8.0

(7.9)

2022PL

4.2

11.0

(10.0)

0.75

6007P

1.7

1.7

(1.5)

1.5

6015P

2.7

2.7

(2.4)

2.2

6022P

3.9

3.9

(3.5)

4.0

6037P

6.1

6.1

(5.5)

5.5

6055P

9.0

9.0

(8.1)

7.5

6075P

11

11.0

(9.9)

11

6110P

17

17.0

(15.3)

15

6150P

22

22.0

(19.8)

Self-cooling

Forced air-cooled Forced air-cooled

IP20 Enclosed type (JEM1030)

150%-60 seconds, 200%-0.5 second

Note 4)

Voltage + 10%, -15%

Note 5)

, frequency±5%

Munsel 5Y-8/0.5

IP20 Enclosed type (JEM1030)

150%-60 seconds, 200%-0.5 second

Note 4)

Voltage + 10%, -15%

Note 5)

, frequency±5%

Munsel 5Y-8/0.5

High-attenuation EMI filter

Note 8)

No filter

Specification

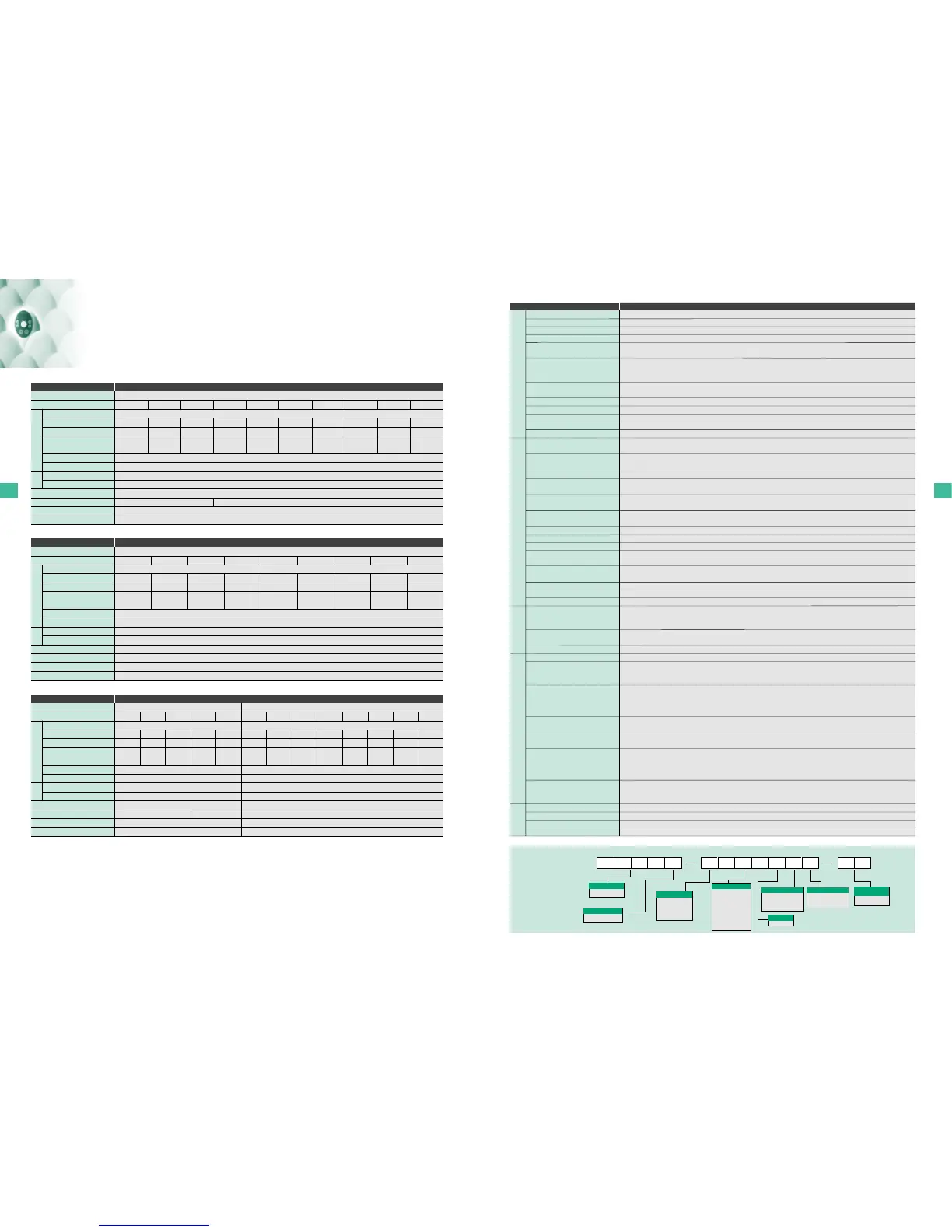

Type Form

SVF 11S 2007PLE WN

TOSVERT

VF-S11 Series

S: 1-phase

None: 3-phase

2: 240V class

(200 to 240V)

4: 500V class

(380V to 500V)

6: 600V class

(525V to 600V)

None: No filter

L: High-attenuation EMI

filter inside

M: Basic filter inside

WN: Sink(Negative)

WP: Source(Positive)

P: Provided

Note) Interface logic can be

switched by slide switch easily.

002: 0.2kW

004: 0.4kW

005: 0.55kW

007: 0.75kW

015: 1.5kW

022: 2.2kW

037: 4.0kW

055: 5.5kW

075: 7.5kW

110: 11kW

150: 15kW

Model name

Number of power phases

Input voltage

Applicable motor capacity

Additional functionsⅠ

None: Standard type

E: Totally enclosed type

U: Open type

Additional functionsⅡ

Interface logic

(Shipment setting)

Operation panel

Contents of the product code

Standard specifications

Loading...

Loading...